Ansys and Siemens Energy Enable Rapid and Cost-Effective Additive Manufacturing for Customers

-Ansys and Siemens Energy are breaking down barriers to additive manufacturing (AM) accessibility, training engineering teams to explore AM solutions with less resources than ever before

-Siemens Energy’s innovative powder bed fusion (PBF) AM printing process will be interoperable with Ansys simulation technologies, helping designers reduce costly physical prototypes and increase product quality

PITTSBURGH, PA, February 18, 2021

Ansys (NASDAQ: ANSS) and Siemens Energy are partnering to offer an improved design process for creating additive manufacturing (AM) parts. The collaboration unites Siemens Energy’s powder bed fusion (PBF) AM printing process with Ansys simulation solutions — empowering AM designers to generate ultra-precise parts, significantly reduce production time and expedite products to market.

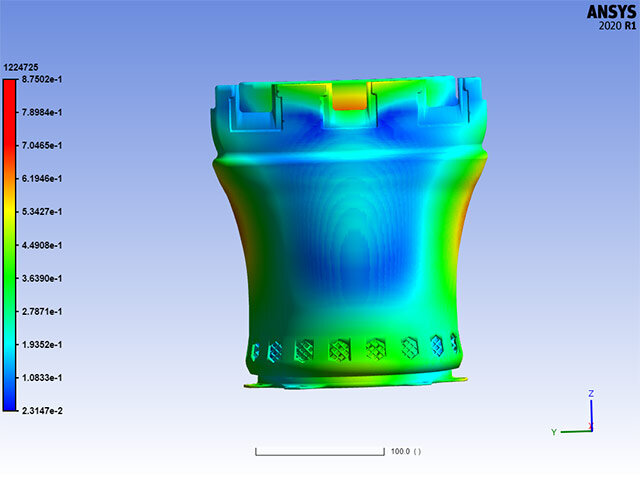

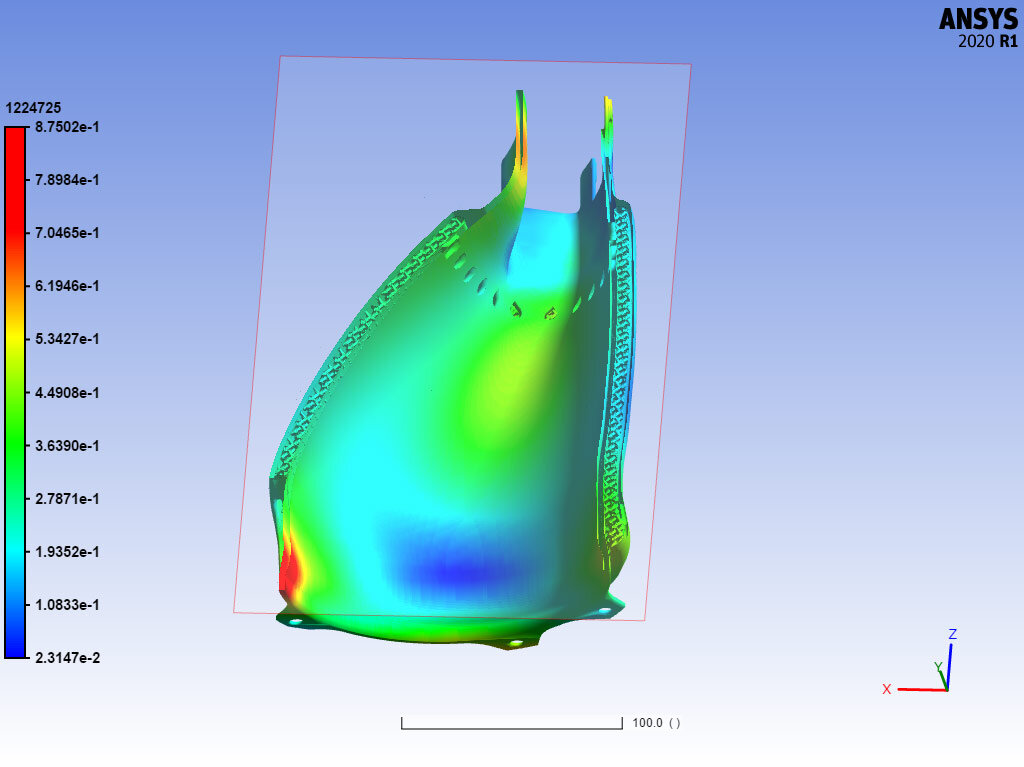

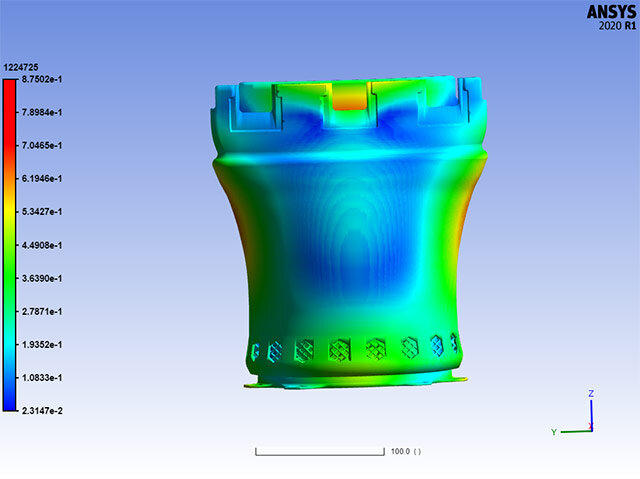

Homogenized lattice structure from Ansys Material Designer captures desired stress redistribution

While many companies across sectors employ AM within their engineering organizations, designers often lack expertise in AM manufacturing, print preparation and simulation tools. This typically results in the production of numerous physical prototypes, unnecessarily inflating budgets and development time. Together, Ansys and Siemens Energy will train engineers to decrease costly production rework and provide affordable next-generation AM printing solutions, so new products can be developed with increased speed and quality for global customers.

Ansys Additive accurately predicts transition print distortion validated post-print

The new partnership powers interoperability between Ansys and Siemens Energy AM technologies to help train designers to affordably produce highly complex parts that cannot be created by conventional manufacturing. Educated on this new AM design process, designers will harness Ansys simulation solutions to lessen the guesswork in product design and validate highly sophisticated part geometries. Leveraging more than a decade of AM experience on gas turbines and other rotating equipment, Siemens Energy can provide real-world application support across the entire design-to-manufacturing value chain for companies looking to bridge toward 3D print capabilities.

“Siemens Energy’s extensive expertise in functional AM printing applications, combined with Ansys’ game-changing AM design technologies improves how organizations of all sizes cost-efficiently produce highly complex parts. Engineering teams’ paramount goal is to print parts right the first time and this partnership makes training them on that task possible,” said Quan Lac, Head of Additive Manufacturing, Americas at Siemens Energy. “Together, we will train our joint customers to design and build products faster, ensuring customers receive new innovations with markedly greater speed.”

“Our partnership with Siemens Energy brings new AM capabilities to engineers across industries, delivering dynamic insights that will radically advance the AM industry and increase new product innovation,” said Shane Emswiler, senior vice president at Ansys. “By breaking the constraints of traditional manufacturing, we are training designers to turn their visions into reality and substantially improve productivity.”