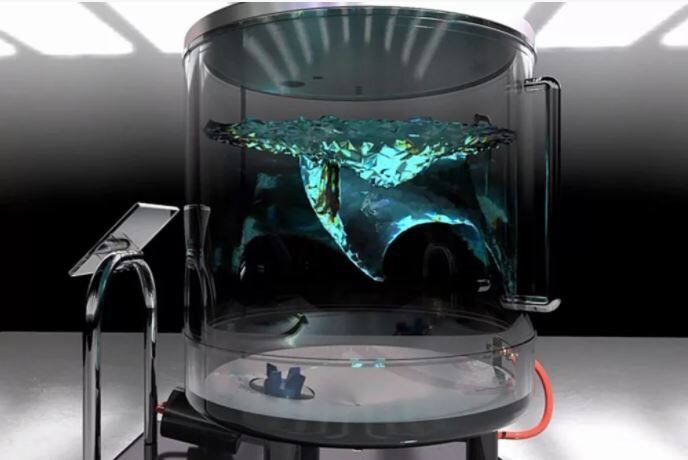

Mixing is crucial in the process industry, serving diverse applications to create customized products. Its primary goal is to blend multiple components into a uniform mixture. This ensures consistent product quality and maximizes downstream process efficiency.

Enhancing Product Quality through Effective Mixing Techniques

Mixing blends substances to create a consistent homogeneous mixture, critical in various industries. It ensures a uniform blend for consistent composition and quality in manufacturing and production processes.

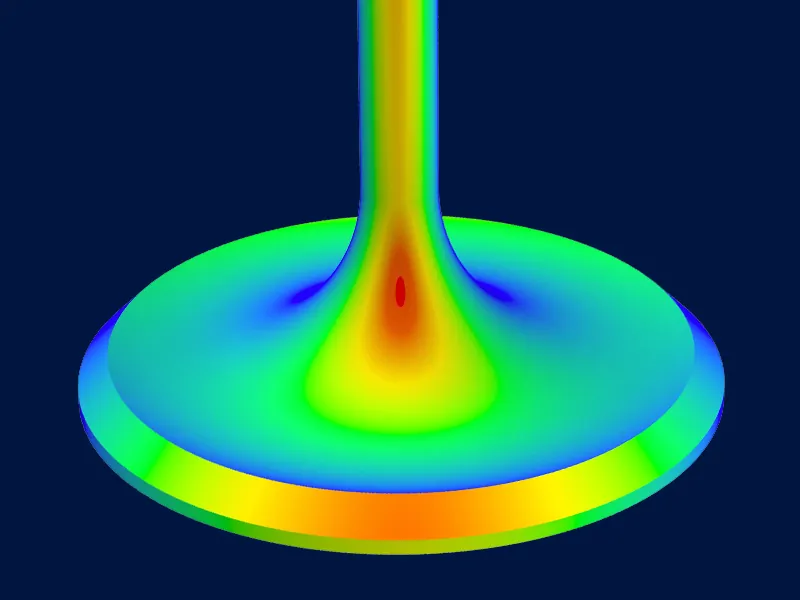

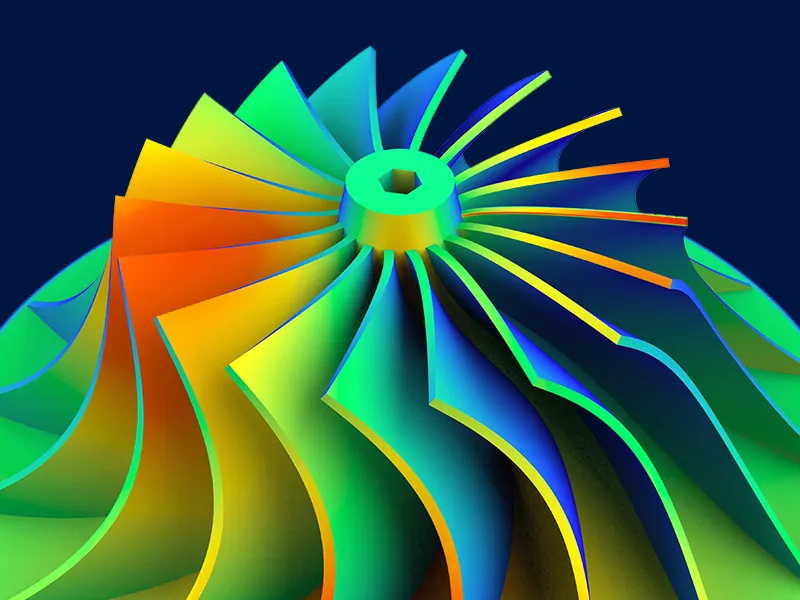

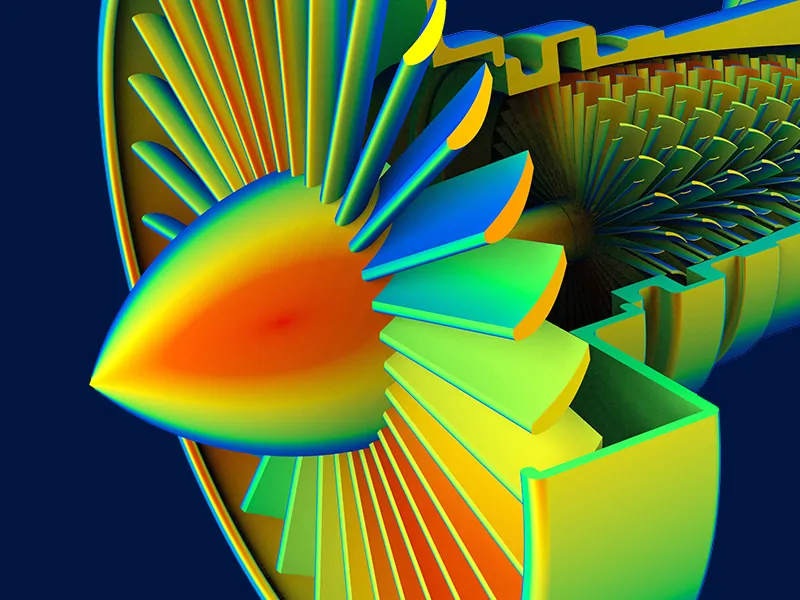

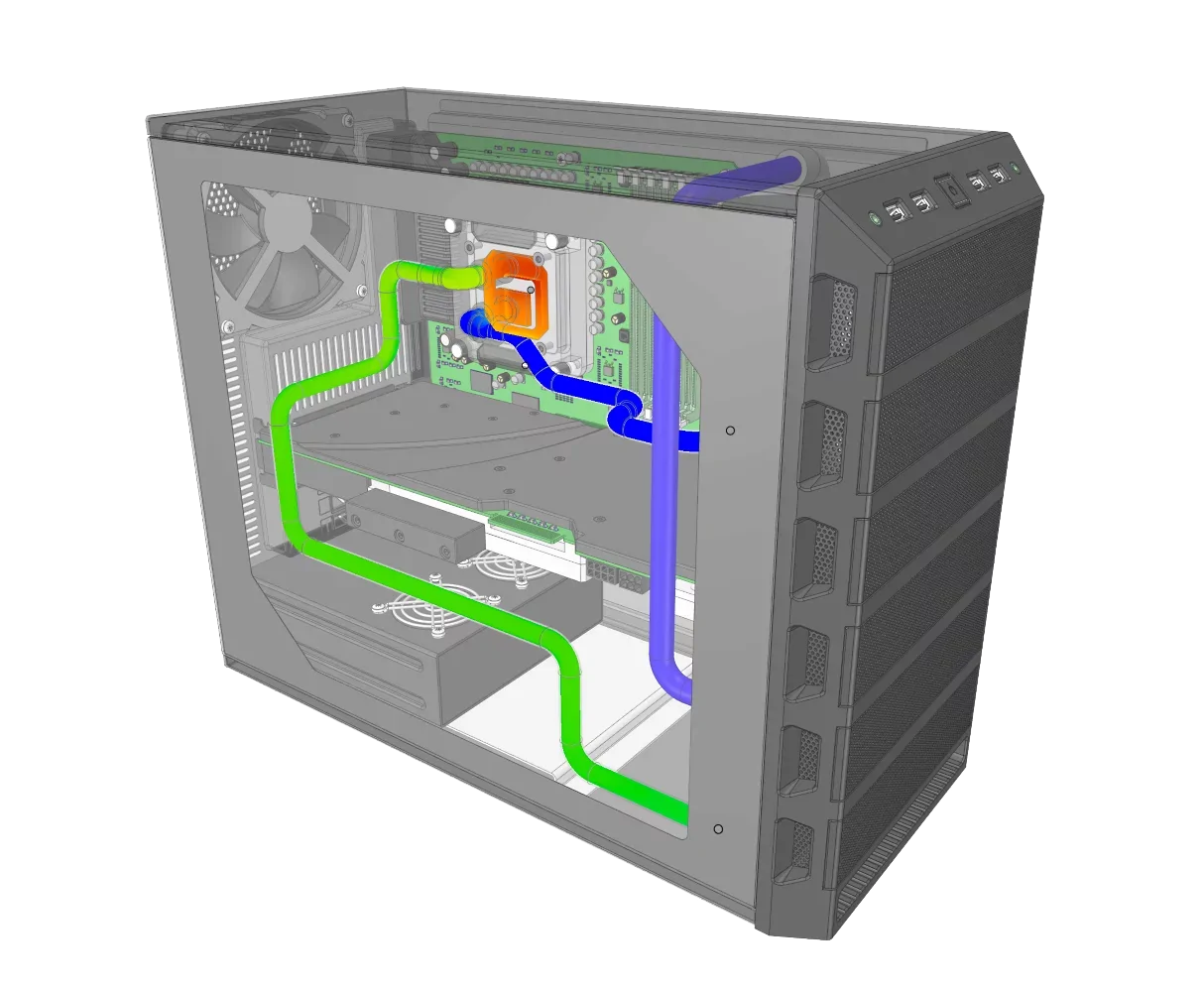

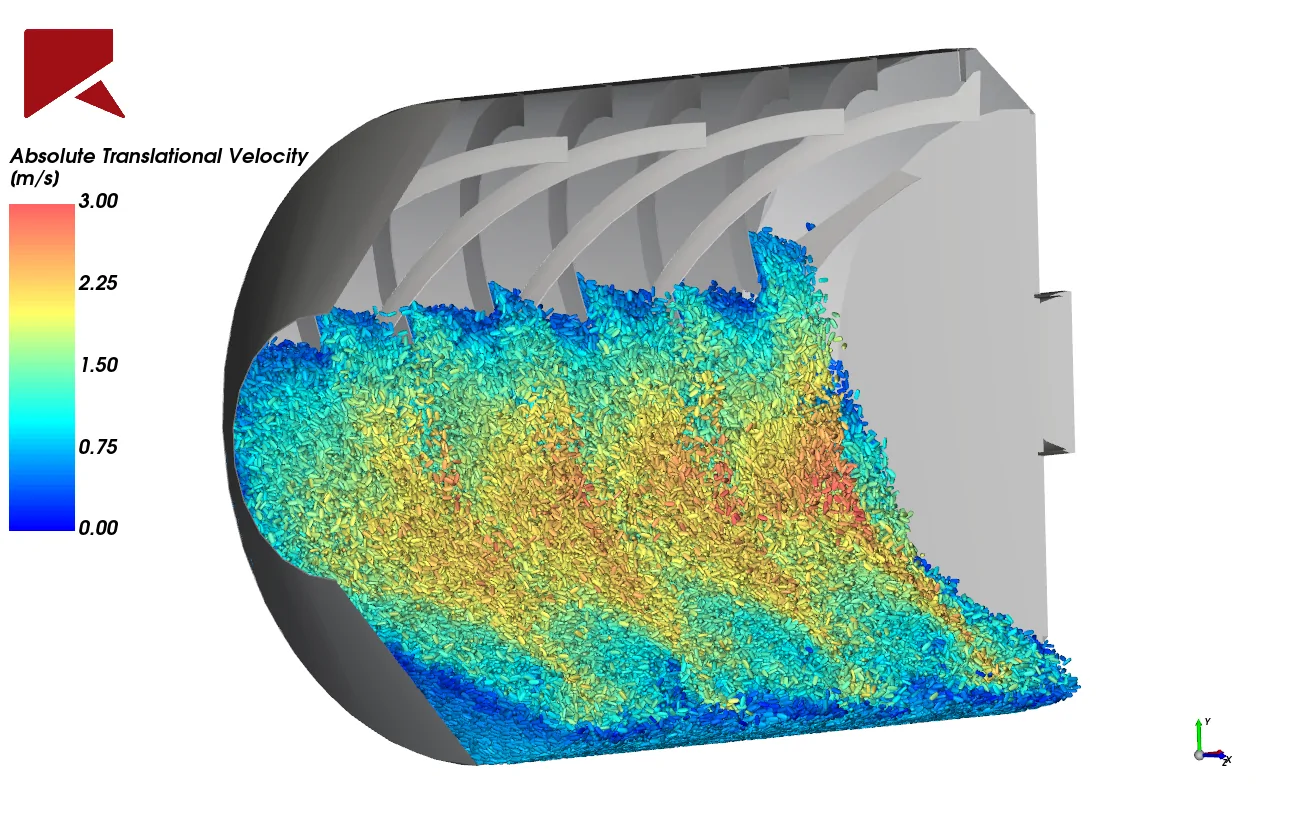

Mixing methods and equipment vary based on process requirements. Options include rotating or agitating impellers, turbines, propellers, or other mixing blades in a vessel. Mixing can also involve pumping substances through pipes or using static mixers with fixed elements for fluid blending.

- Physics models

- Data analytics

- Engineering know-how

- Physics models

- Data analytics

Benefits

White Paper

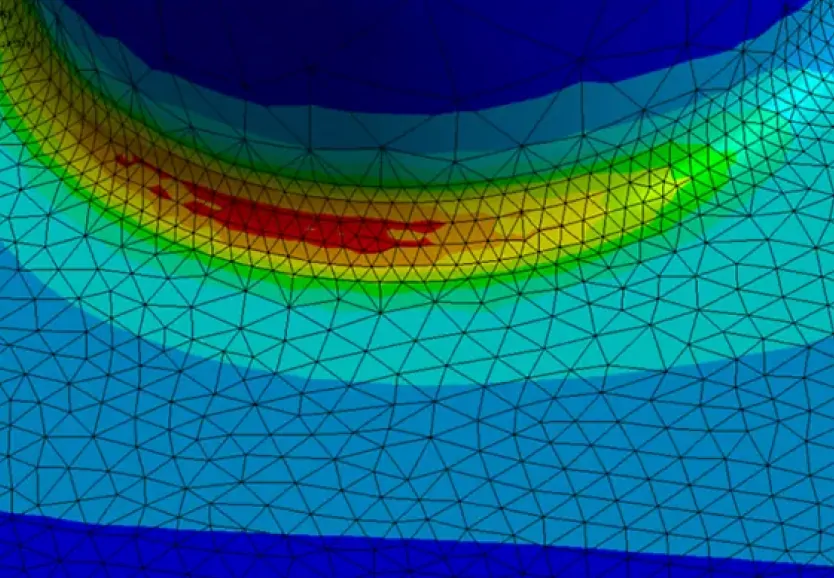

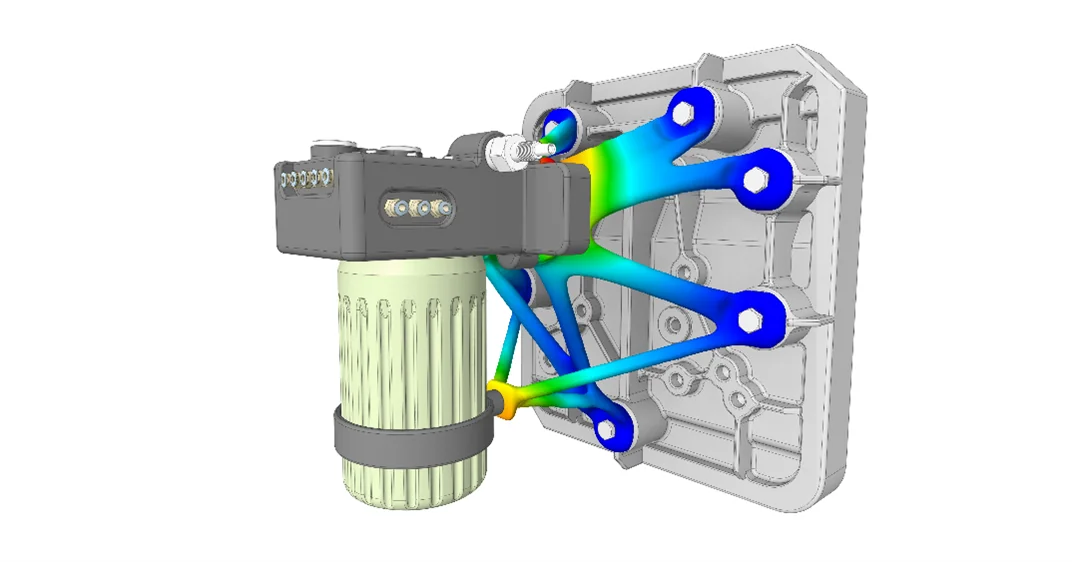

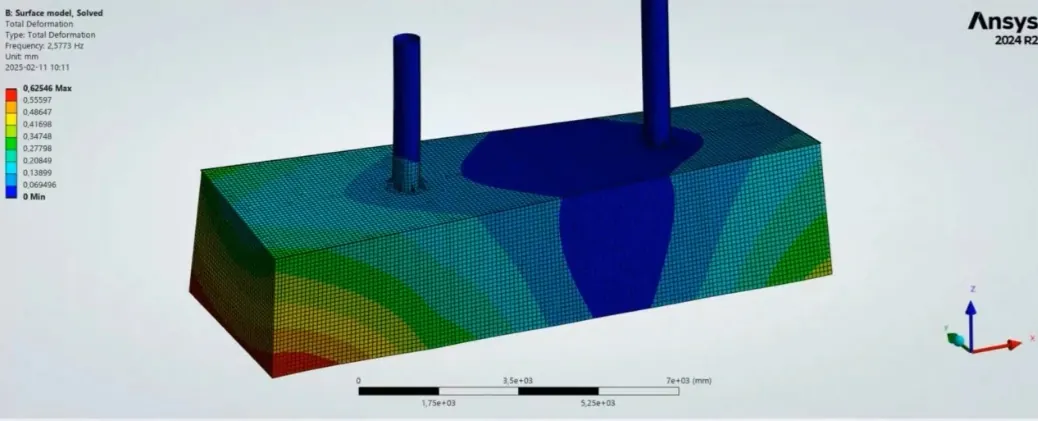

CFD simulation of stirred tank mixing processes using Ansys

This PDF provides an overview of using Ansys for CFD simulations of stirred tank mixing processes. Discover how this powerful software enables accurate modeling, analysis, and optimization of fluid flow behavior in stirred tanks. Enhance design, optimize processes, and improve efficiency with Ansys CFD simulations.

How We Can Help

We enable our customers design better products, reduce risk, and accelerate time to market. At EDRMedeso we are committed to driving innovation by providing leading simulation technologies powered by knowledge transfer.

We can help you utilize Ansys Fluid Mixing application by providing expert advice on simulation setup and analysis, as well as customized training to help you learn the software and improve your simulation skills. Our team can also assist you in developing customized workflows to solve complex fluid mixing problems specific to your industry or application.

Speak to an Expert

Reach out to our expert for help or advice

Over the years the focus has shifted from working primarily in the support team to the presales team, supporting the sales process. The sales process is also developing rapidly and instead of purely focusing on specific tools I promote the full portfolio of products that we utilize to assist the whole product development process.