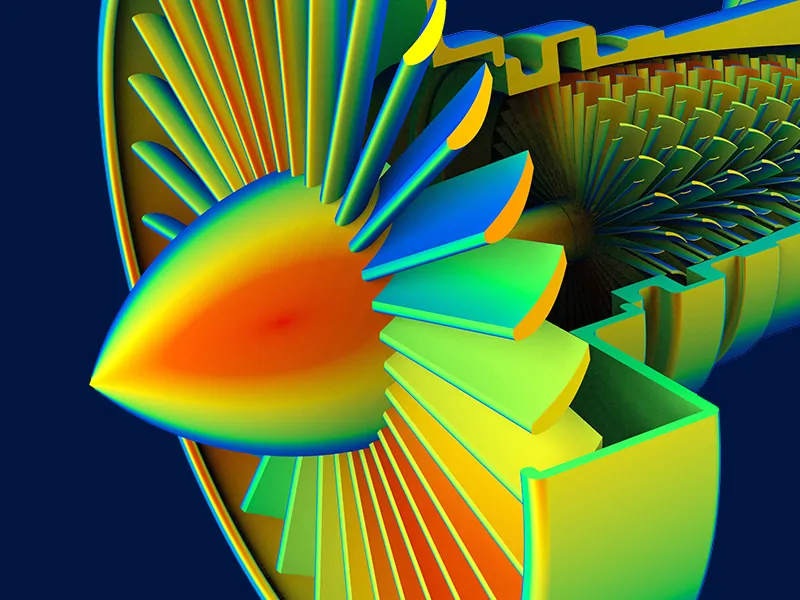

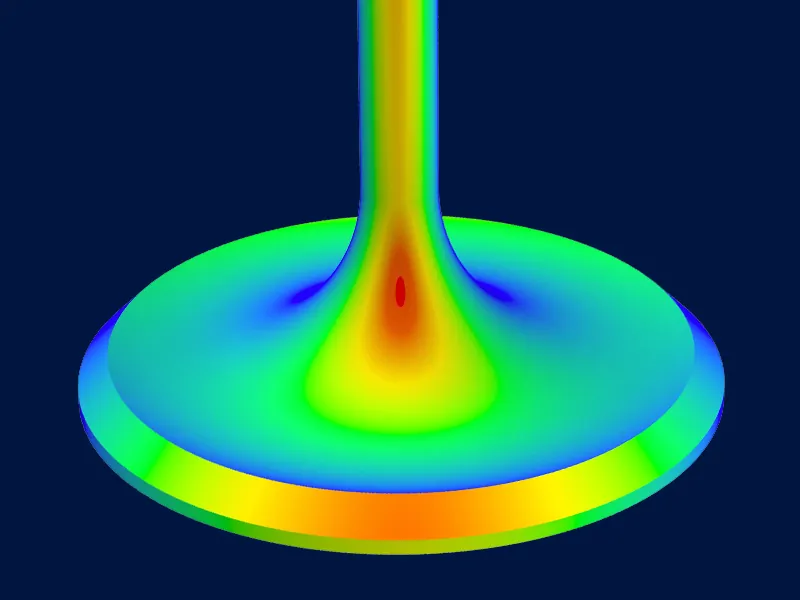

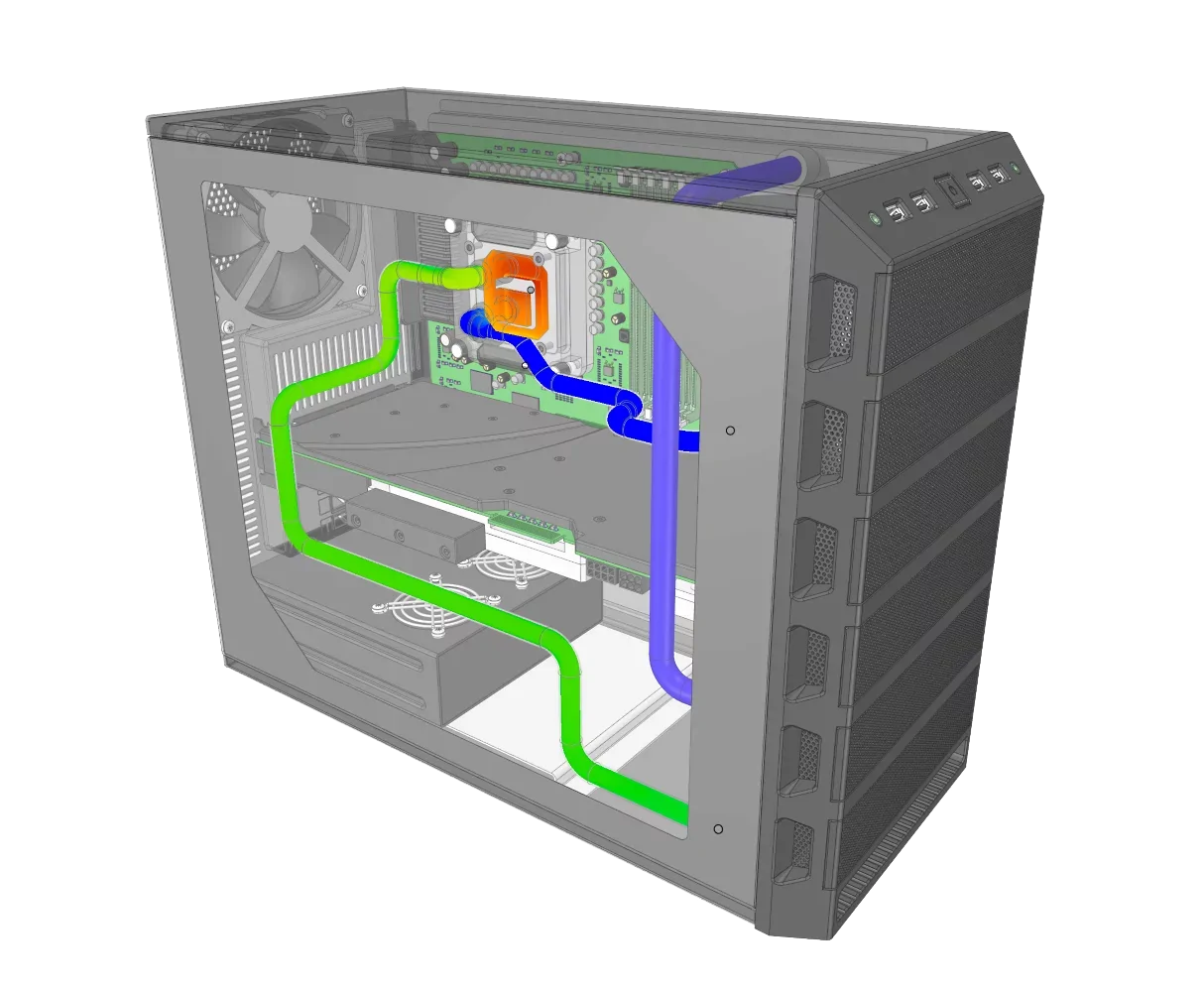

Ansys CFX® (computational fluid dynamics software) enables engineers and researchers to simulate fluid flows, heat transfer, and other related phenomena in a wide range of applications. It uses a finite volume method to discretize the governing equations of fluid flow and solves them numerically to predict the behavior of fluids in complex geometries.

Visualizing and Analyzing Simulation

With Ansys CFX®, users can model a variety of fluid flow scenarios, including turbulent flows, multiphase flows, and combustion processes. It also includes advanced features for heat transfer simulations, such as conjugate heat transfer and radiation heat transfer. Ansys CFX® can be used in a wide range of industries, including aerospace, automotive, energy, and biomedical engineering.

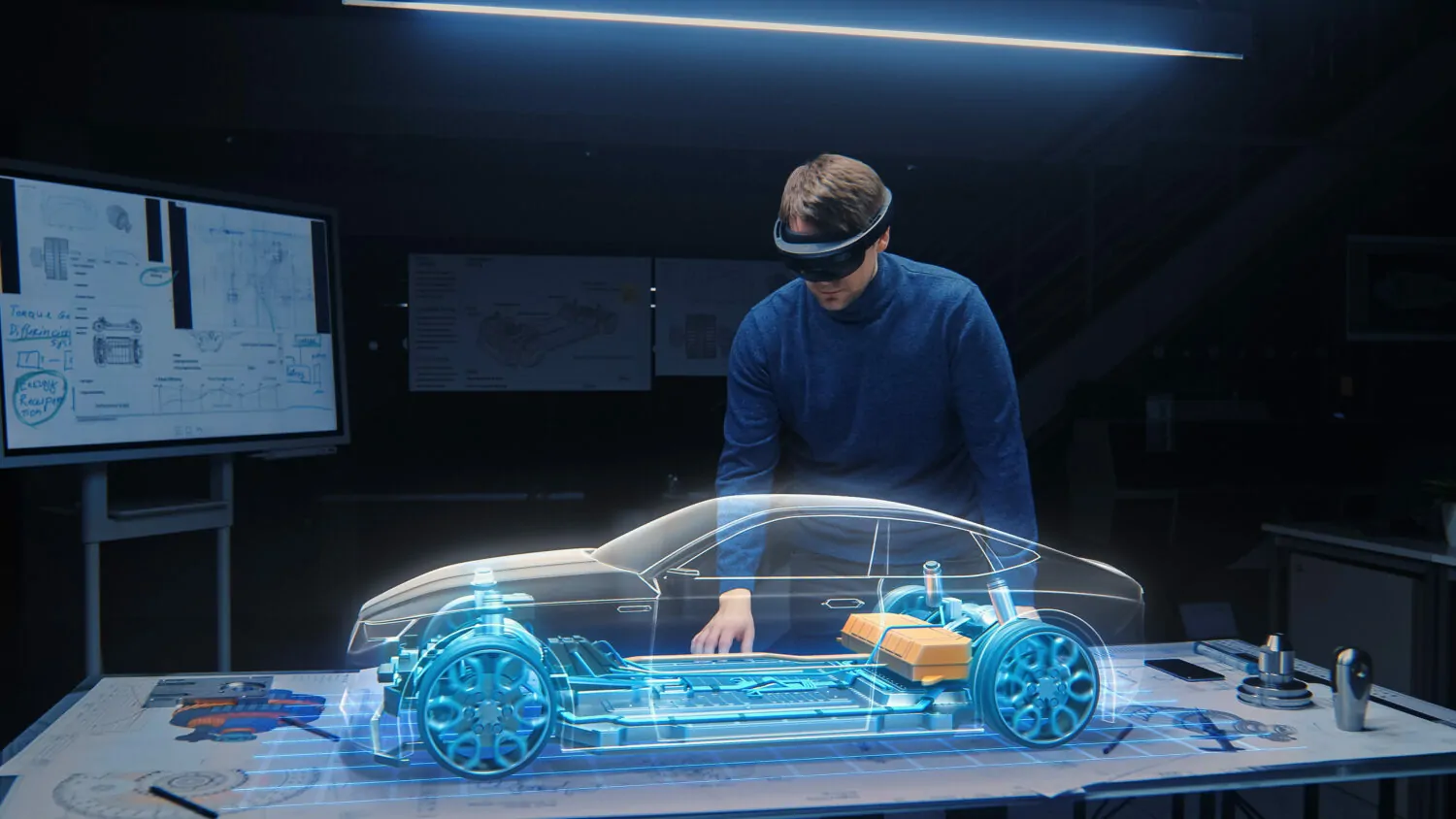

The software offers a user-friendly interface and powerful post-processing tools for visualizing and analyzing simulation results. It also supports customization through its scripting capabilities, allowing users to automate repetitive tasks and develop their own simulation workflows.

Key Features

Solve a variety of fluids-related problems with high levels of accuracy and unmatched speed

- Blade design and optimization

- Aeromechanics

- Industry leading turbulence modeling

- Nuclear Wall boiling

- Advanced material modeling

Benefits

Case Study

ARC Utilizes Ansys Simulation to Increase Efficiency in the Development of 3D-printed Rocket Engines

With the importance of quick investigation into design performance, engineering simulation is an integral part of ARC’s operational environment and the space/defense industry

Find out how ARC used simulation to create truly innovative and optimal designs for the industry.

Speak to an Expert

Reach out to our expert for help or advice