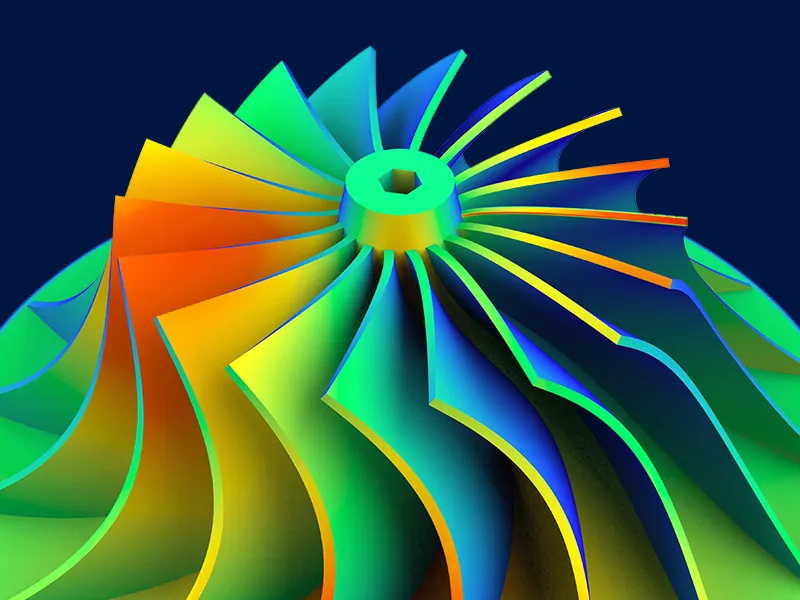

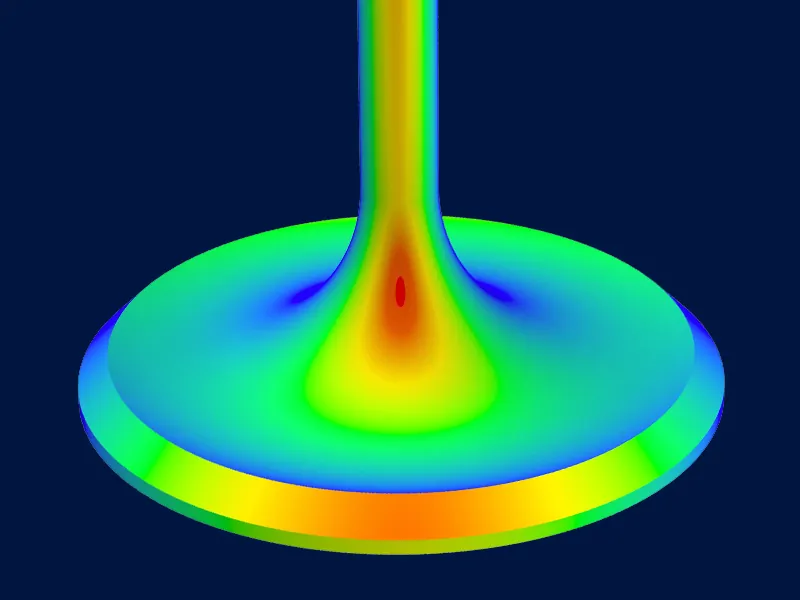

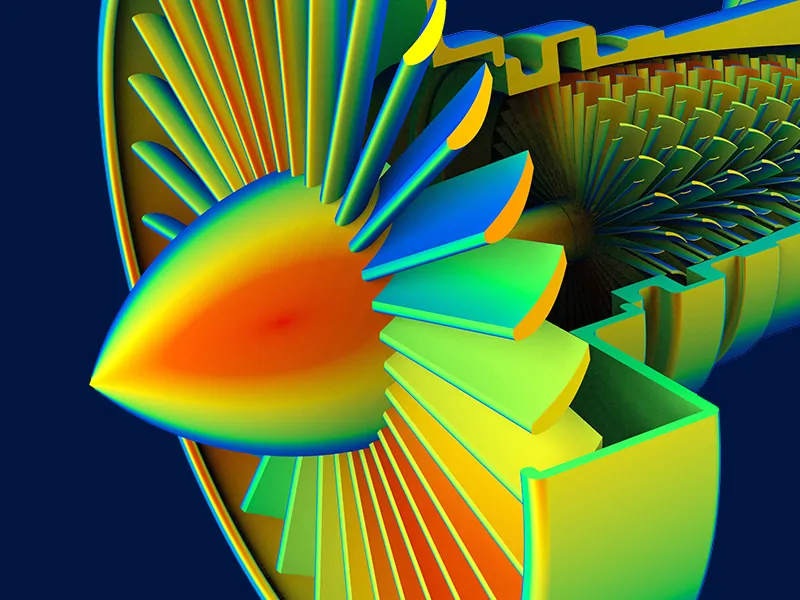

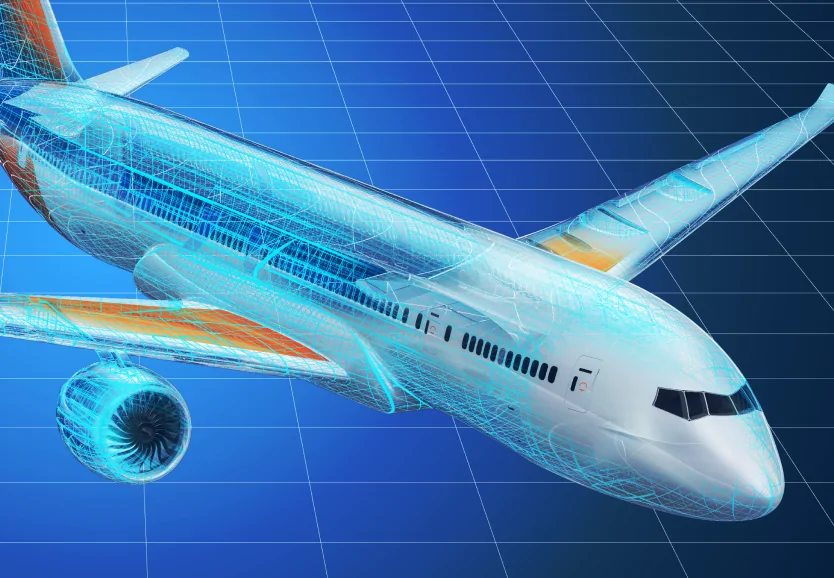

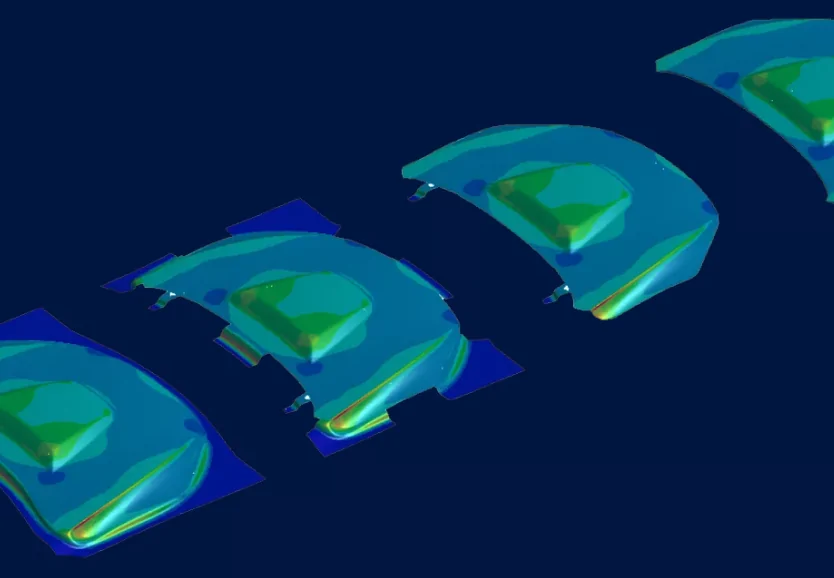

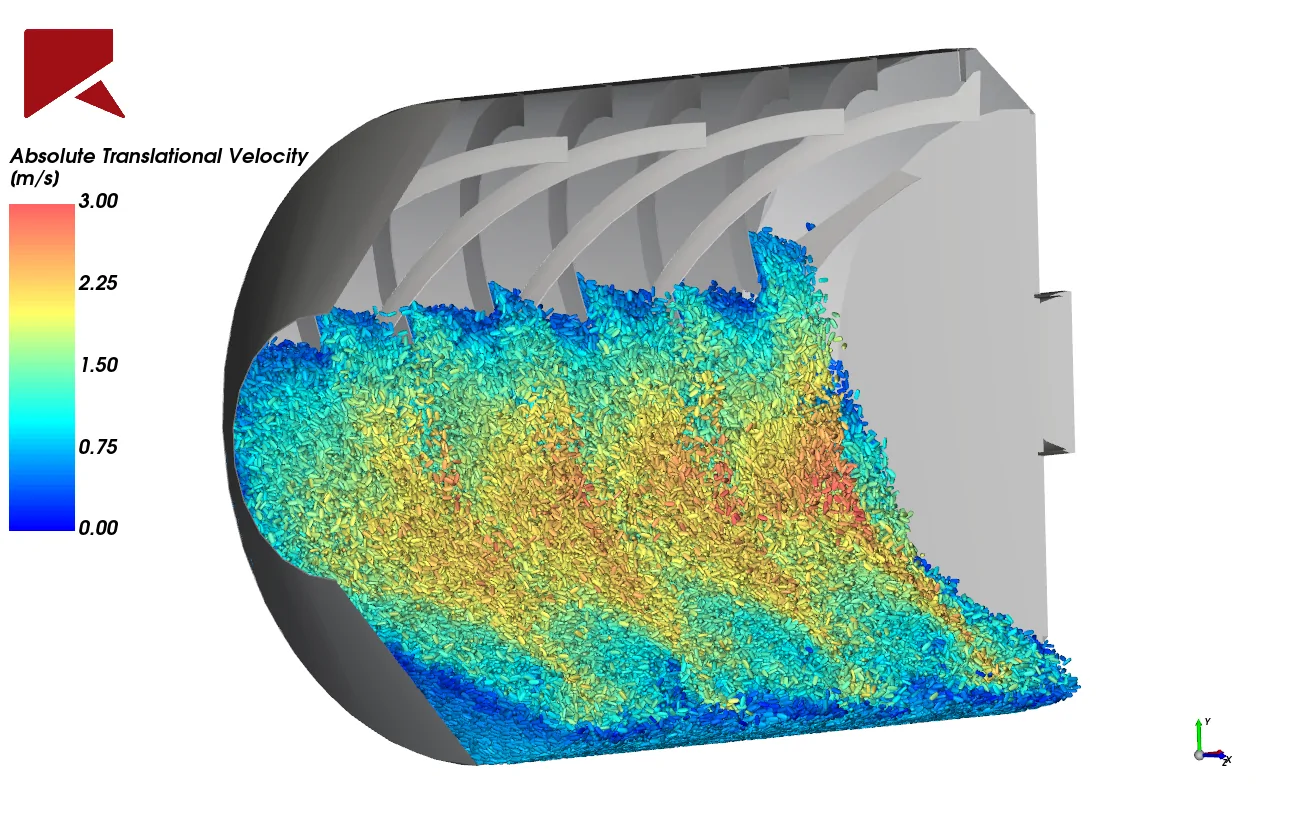

Rotating machinery, or turbomachinery, involves a component that transfers energy between a fluid and the machine. This transfer can occur from the rotor to the fluid, making it a pump or a fan, or from the fluid to the rotor, making it a turbine. Examples of such machinery include fans, pumps, compressors, turbines, and wind turbine generators.

Optimizing Rotating Machinery Design with Ansys Software

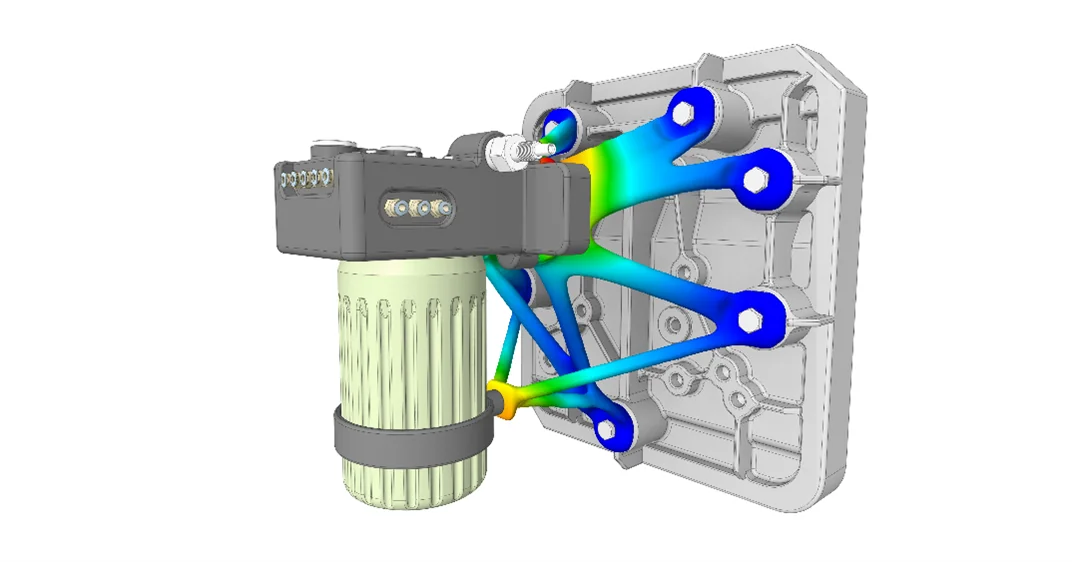

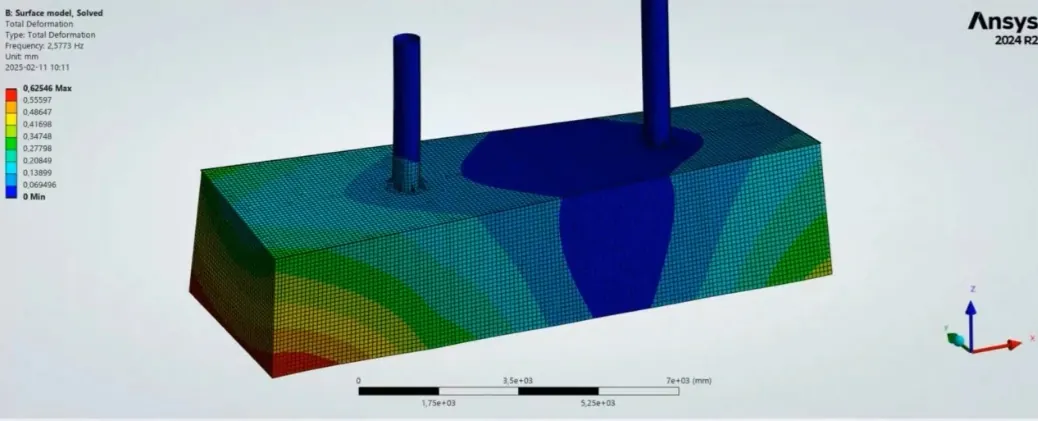

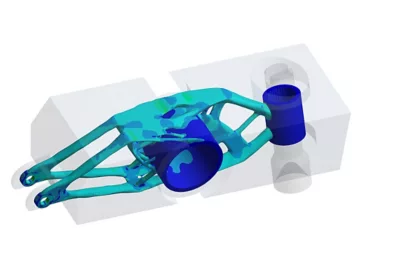

Ansys Rotating Machinery application provides advanced software that assists in the design of various types of rotating machinery equipment and enables rapid iteration and improvement of designs. By offering valuable insights into key metrics before the manufacturing and testing phase, simulation proves to be a dependable means of enhancing efficiency while lowering development costs and reducing time to market.

- Structural Durability and Reliability

- Increased Efficiency

- Process Integration and Design Optimization

- Predictive Maintenance and Digital Twin

Benefits

Predict Risks During Product Development

Increase Efficiency and Productivity

Reduce Time-to-Market

Cost Reduction

How We Can Help

We enable our customers design better products, reduce risk, and accelerate time to market. At EDRMedeso we are committed to driving innovation by providing leading simulation technologies powered by knowledge transfer.

Our team of experienced engineers can provide expert guidance on simulation setup, analysis, and interpretation. We can also assist you in developing customized workflows to solve complex rotating machinery problems specific to your industry or application.

Speak to an Expert

Reach out to our expert for help or advice