Simulate the response of materials to short periods of severe loading. Ansys LS-Dyna® (nonlinear dynamics structural simulation software) is the industry leading explicit simulation software used for applications like drop tests, impact and penetration, smashes and crashes, occupant safety, and more.

Vast array of capabilities to simulate extreme deformation problems

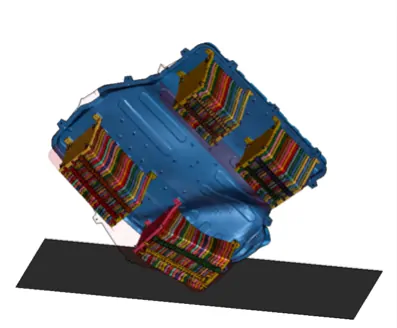

Ansys LS-Dyna® is the most used explicit simulation solution in the world and is capable of simulation the response of materials to short periods of severe loading. Its many elements, contact formulations, material models and other controls can be used to simulate complex models with control over all the details of the problem.

Engineers can tackle simulations involving material failure and look at how the failure progresses through a part or a system. Models with large amounts of parts or surfaces interacting with each other are also easily handled, and the interactions and load passing between complex behaviors are modeled accurately. Using computers with higher numbers of CPU cores can drastically reduce solution times.

Key Features

Ansys LS-DYNA® elements, contact formulations, material models and other controls can be used to simulate complex models with control over all the details of the problem.

- Implicit and Explicit Solvers

- Frequency Domain Analysis

- ICFD for Incompressible Fluid

- Electromagnetics Solver

- Multiphysics Solver

- Particle Methods

- Contact – Linear and Nonlinear

- Adaptive Remeshing

- Meshless – SPH and ALE

- Advanced CAE

- Supporting Tools

Benefits

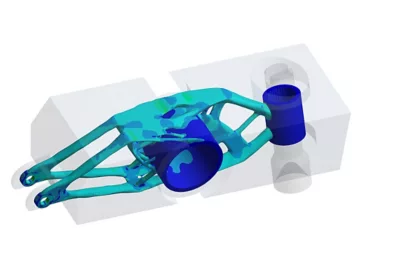

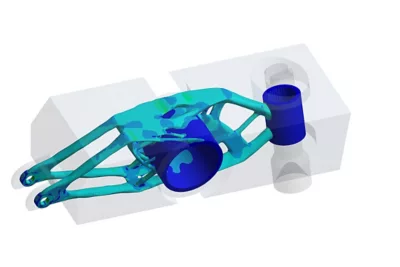

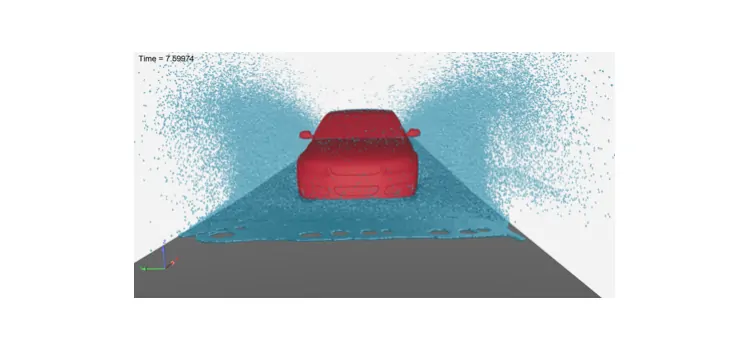

Case Study

Racing to Victory: NASCAR Meets an Aggressive Launch Schedule with Ansys Cloud™

NASCAR was on track to launch a revolutionary Next Gen car design that would change the face of stock car racing. Then the COVID-19 pandemic struck, eliminating the possibility of physical prototypes and tests. The NASCAR engineering team needed to verify the safety of its car design via numerically large Ansys LS-DYNA® crash simulations — getting results in real time and iterating quickly.

Speak to an Expert

Reach out to our expert for help or advice