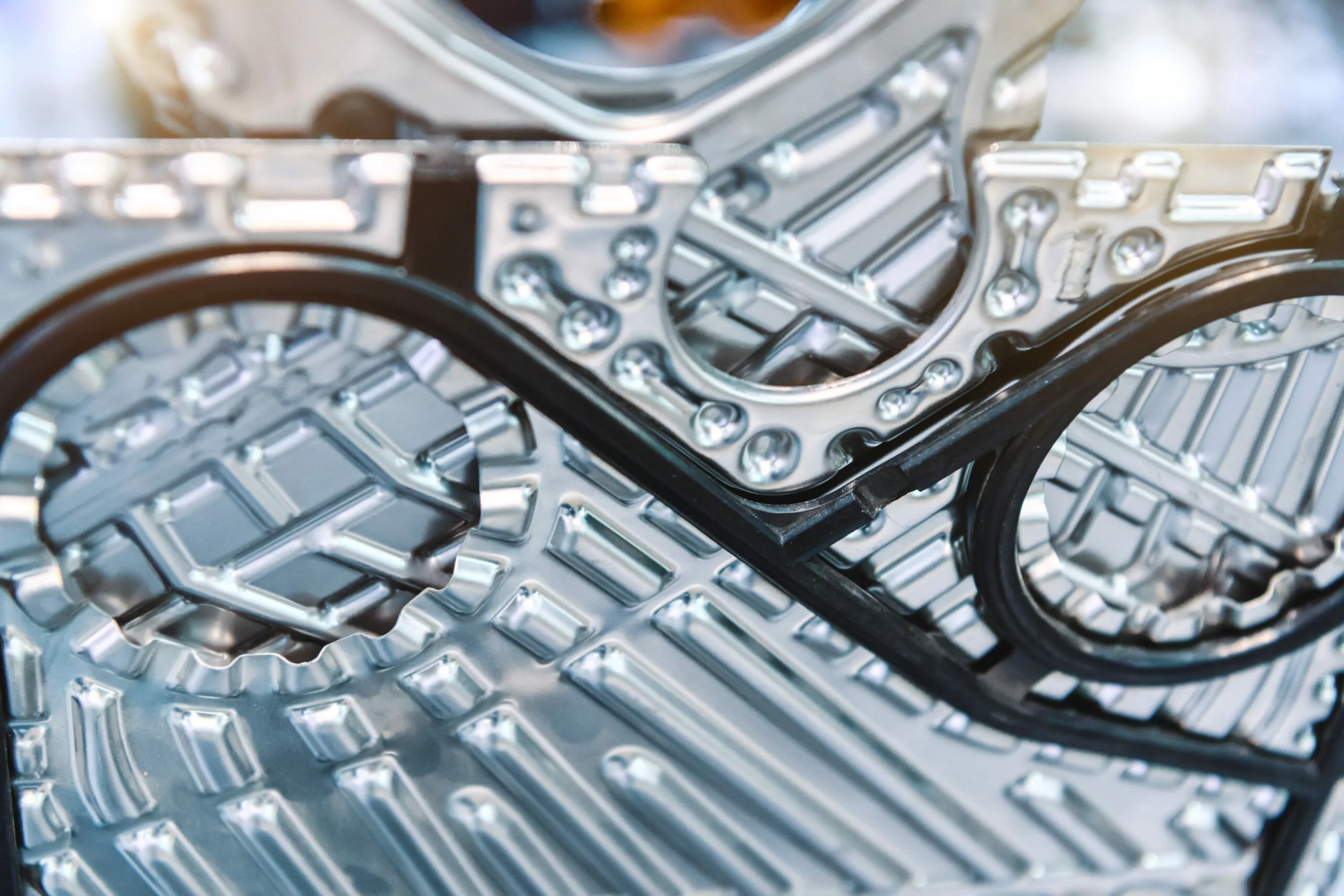

Heat exchangers have been used for many years in different applications. Typically we find them in HVAC, refrigeration, power generation, and chemical processing. From an environmental point of view, they are important for us in order to make use of residues of heat and reuse.

Exploring Thermal Energy Transfer in Heat Exchangers

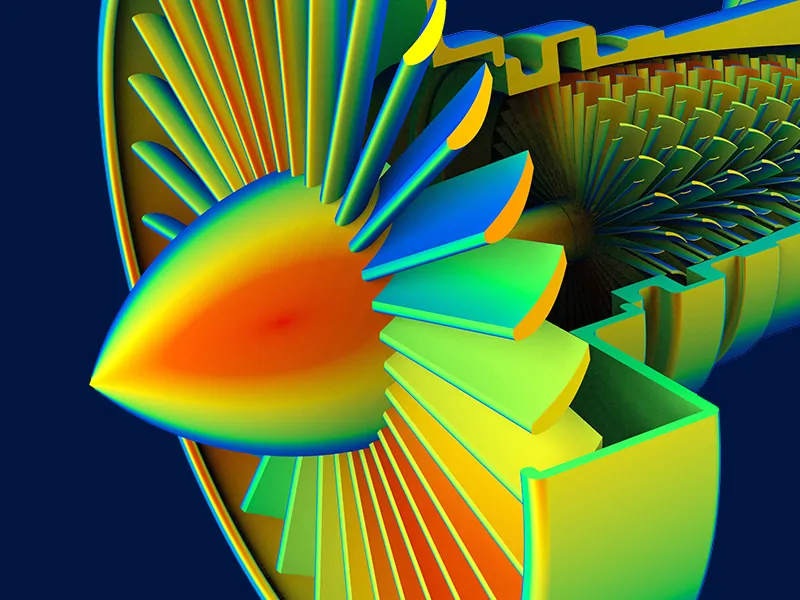

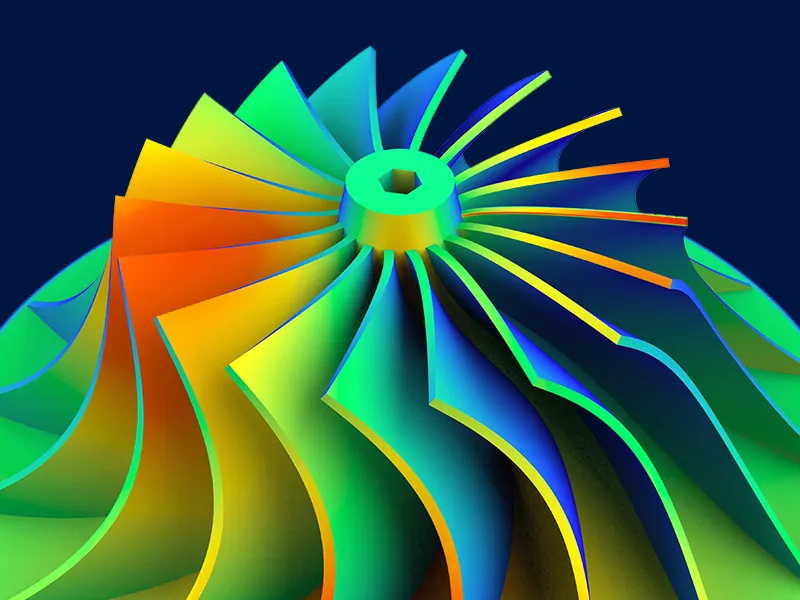

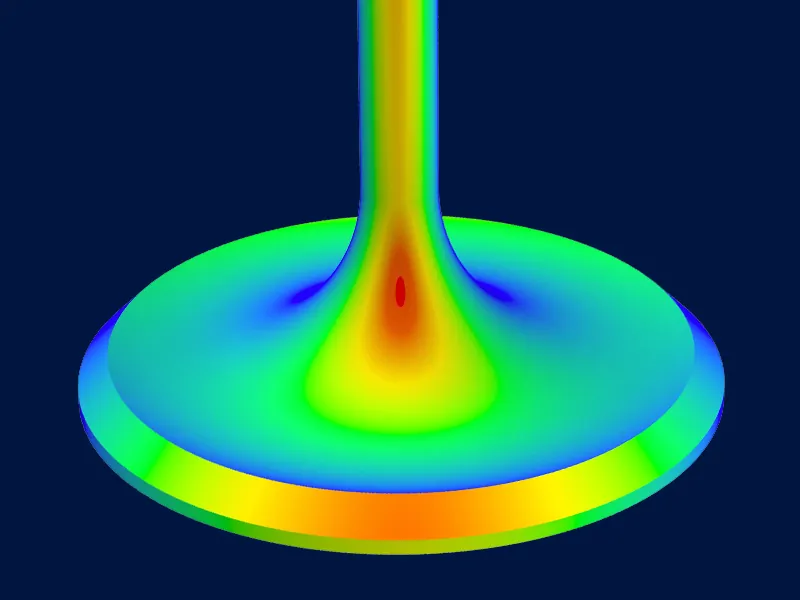

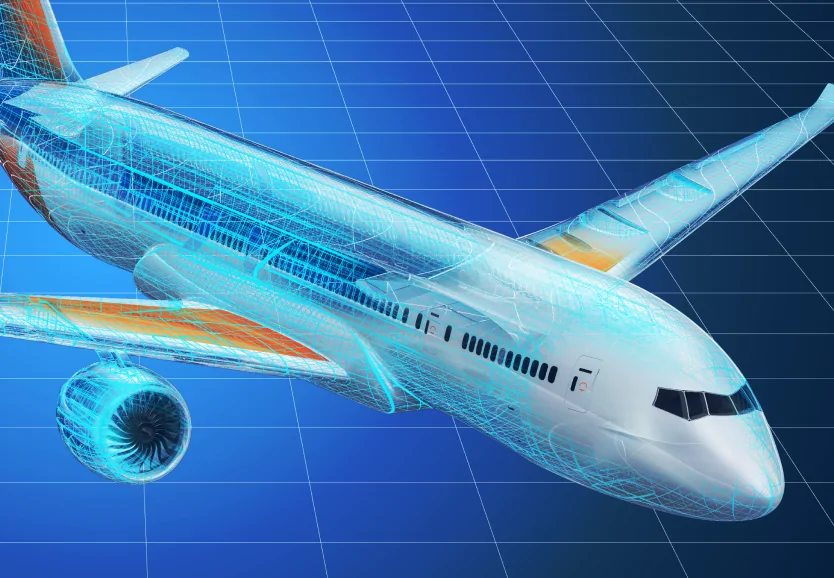

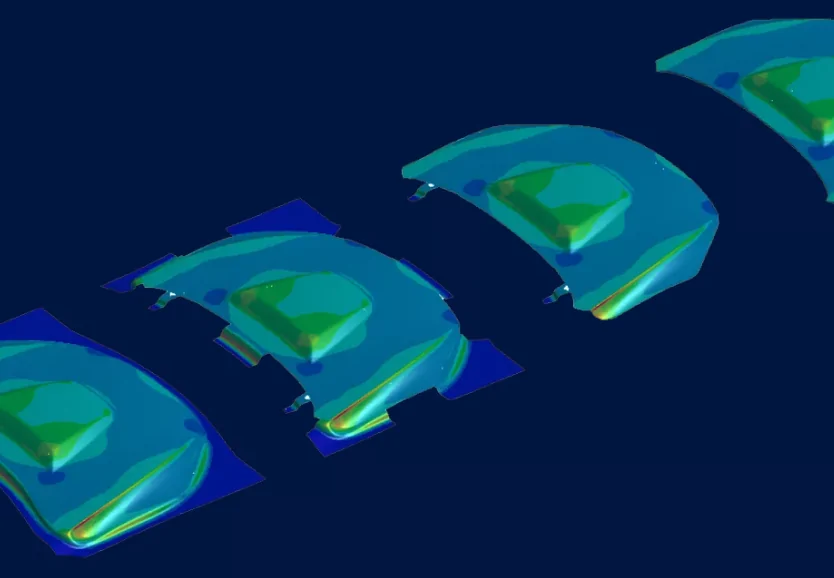

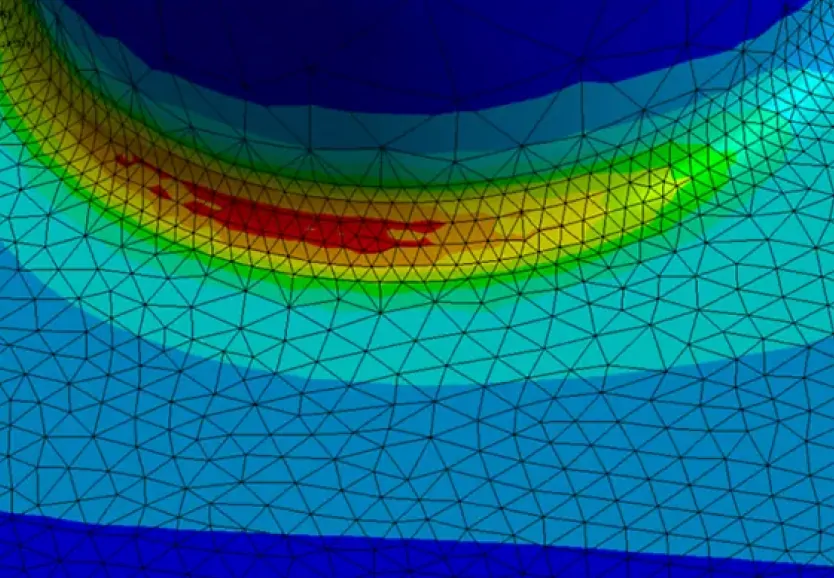

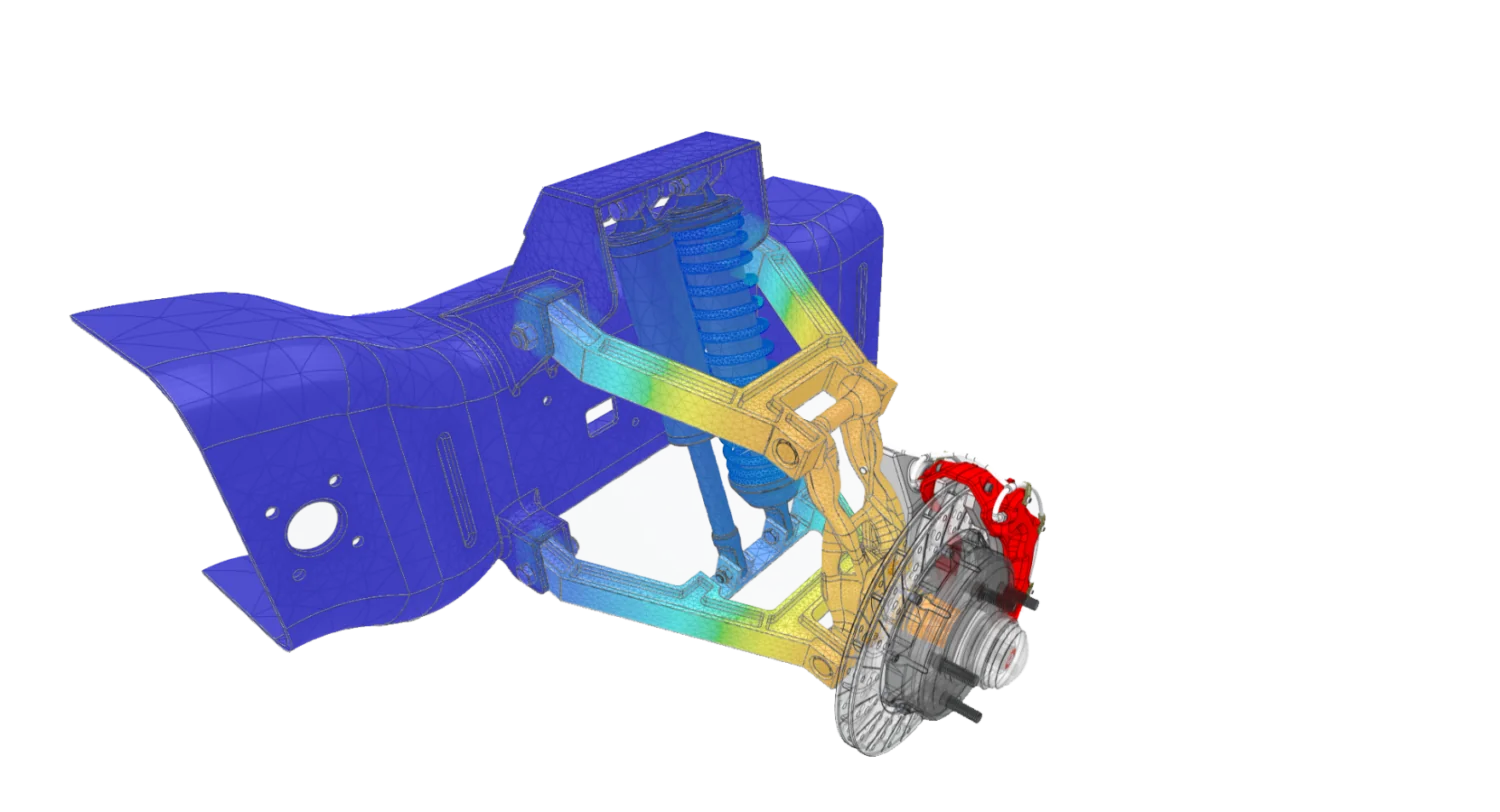

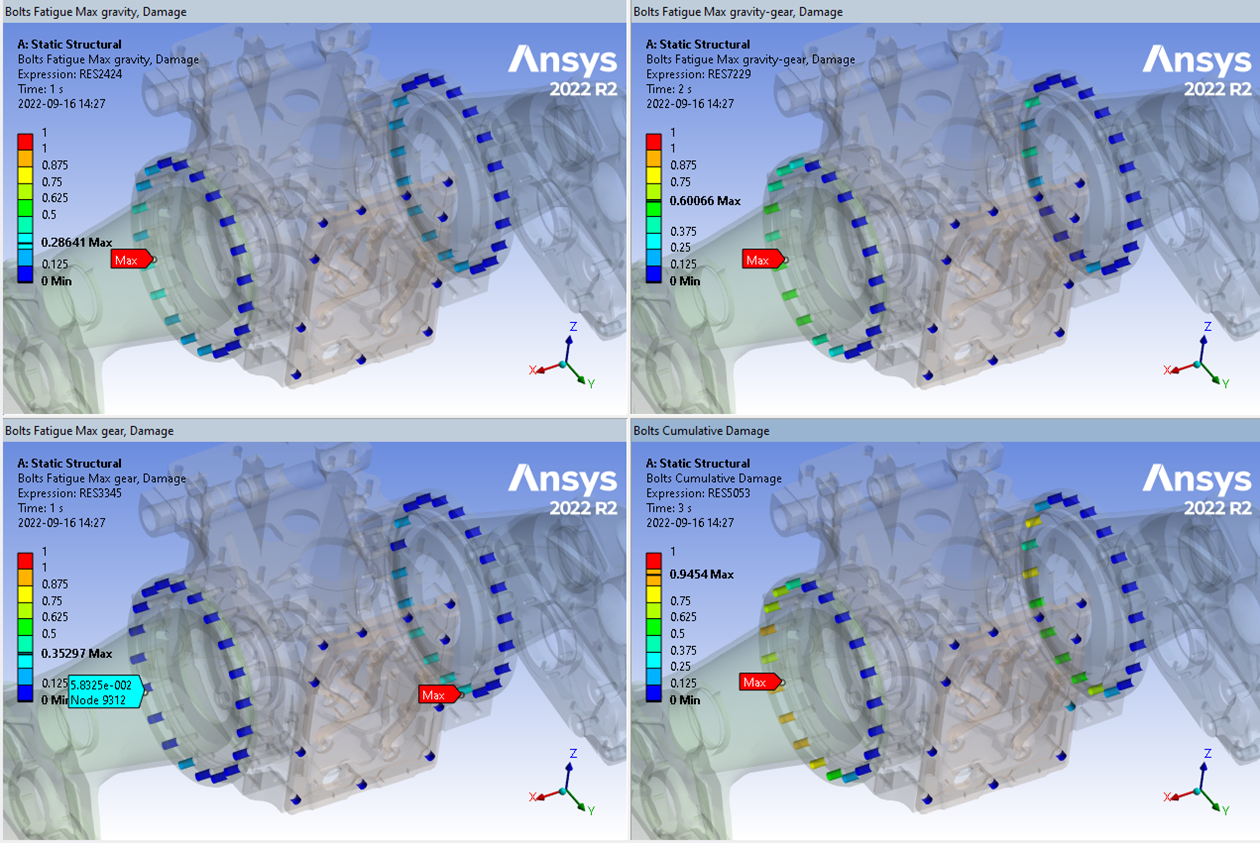

A heat exchanger transfers thermal energy between fluids without mixing them. Designing a heat exchanger involves considering factors like thermal fatigue, FSI, fluid flow, and phase transitions. Interaction between components impacts system performance, such as in a carnot cycle.

Heat exchangers have various designs, typically involving tubes or plates for fluid flow and conduction-based heat transfer. Examples include car radiators and condensers/evaporators in refrigeration and air conditioning systems.

Benefits

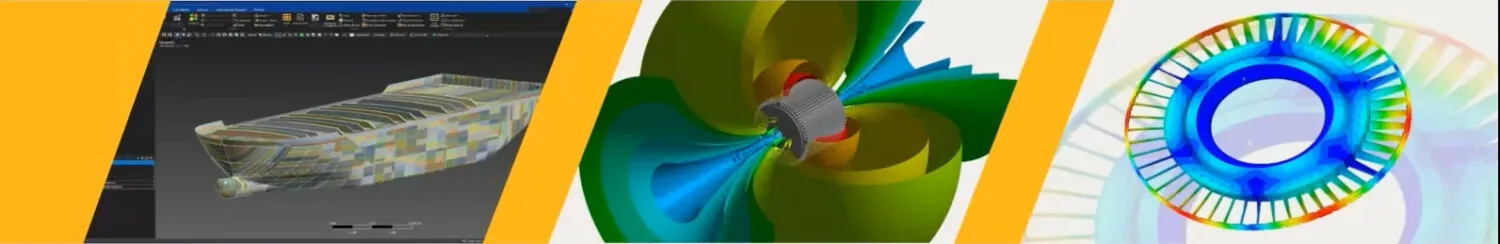

How We Can Help

We enable our customers to design better products, reduce risk, and accelerate time to market. At EDRMedeso we are committed to driving innovation by providing leading simulation technologies powered by knowledge transfer.

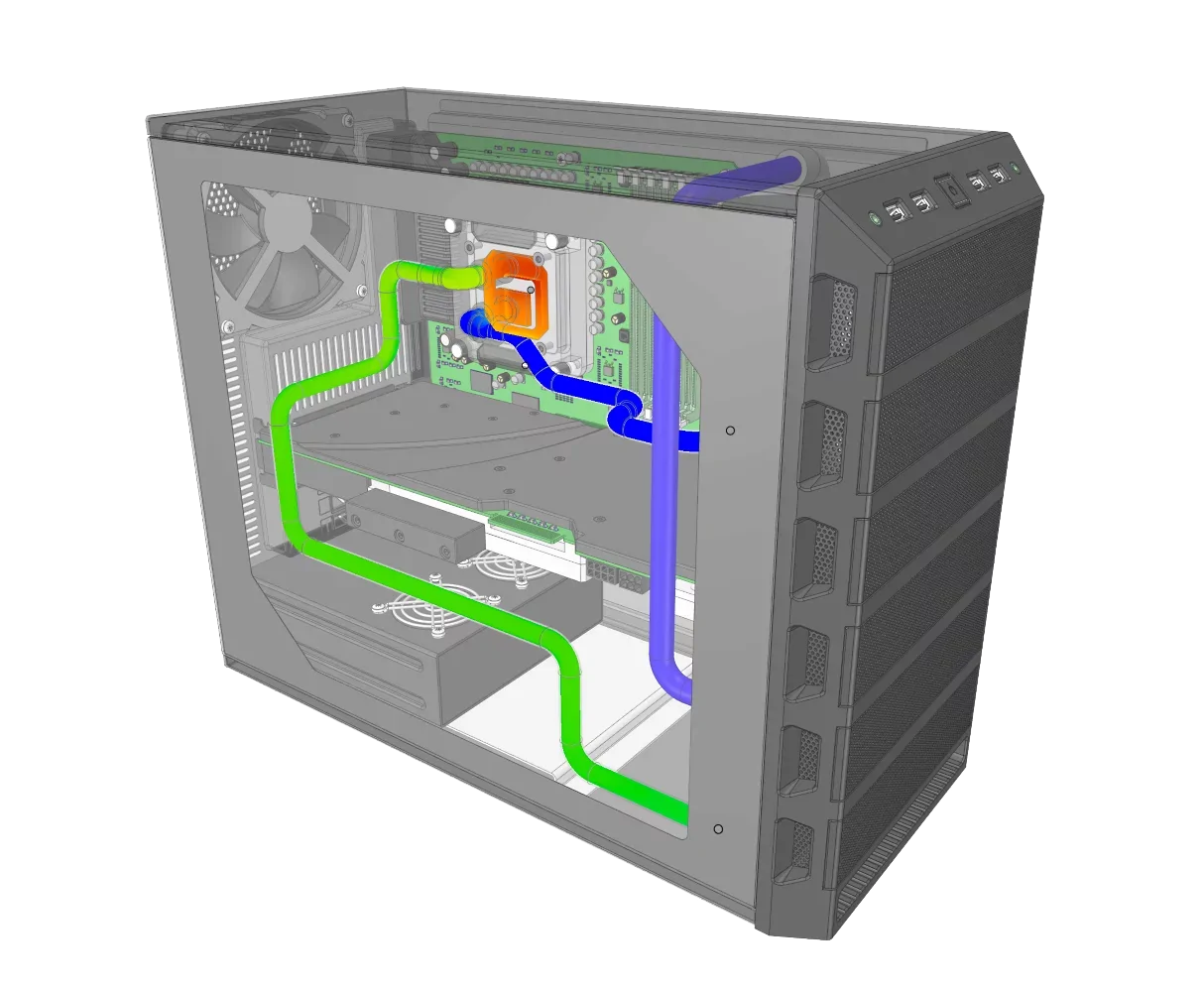

We can assist you in developing customized workflows to solve complex heat exchanger problems specific to your industry or application. Our team of experienced engineers and simulation experts can provide expert guidance on simulation setup, analysis, and interpretation.

Speak to an Expert

Reach out to our expert for help or advice