EDRMedeso Productivity Tools – short historical review & 2022R2 update

The Mechanical productivity tools or “apps” are some of the products from the Technology and Innovation group managed by Frode Halvorsen (CTO) at EDRMedeso. In the team we also find Fredrika Dahlberg (Innovation Manager) and Magnus Gustafsson (Senior Application Manager and Developer) who has driven the app initiative at EDRMedeso for many years.

It all started back in 2016 when Ansys opened for third party licensed apps with the release of Ansys R17 and the creation of Ansys Appstore where you could find and download the apps. We (EDRMedeso) had experimented with some small free and paid apps for some time, but this new solution opened new possibilities that we embraced, says Frode.

Many of the small apps are the offspring from project work where a certain feature was missing, like the “CSV Plot” app that allows plotting of external results on the model. This app is one of the most downloaded apps of all time. With my background from industry where bolts, welds and reporting are a common simulation pain, I started to develop the tools I was missing when doing project work. This embryo that started as a “hobby/side project” has now become our three bestselling apps, says Magnus. As a developer it is fun to be challenged by the users to implement innovative ideas to improve the apps. You may have your own ideas on what to do next but also hearing it from the customers gives you confidence to continue.But how do you take an idea and scale it to be a success you may ask? We turn to Fredrika to hear her view of innovation at EDRMedeso.

Many of the small apps are the offspring from project work where a certain feature was missing, like the “CSV Plot” app that allows plotting of external results on the model. This app is one of the most downloaded apps of all time. With my background from industry where bolts, welds and reporting are a common simulation pain, I started to develop the tools I was missing when doing project work. This embryo that started as a “hobby/side project” has now become our three bestselling apps, says Magnus. As a developer it is fun to be challenged by the users to implement innovative ideas to improve the apps. You may have your own ideas on what to do next but also hearing it from the customers gives you confidence to continue.But how do you take an idea and scale it to be a success you may ask? We turn to Fredrika to hear her view of innovation at EDRMedeso.

The aim of the Technology and Innovation group is to help our customers by adding new products or vendors to our portfolio that bring value to our customers, Fredrika says. When we work with innovation at EDRMedeso we start with customer needs and develop a product or onboard a vendor that best solve this need. The apps are a great example of such project – Magnus found that something was missing and realized that more than him had a need for certain features and started the project. Today that project has turned into a great product with partners around the world!

And the customers’ feedback is still in focus, Fredrika continues. It is exactly one year since the re-launch of the apps and during this period we have received a lot of feedback from our customers. Valuable input that has been the guiding star for the latest updates, or “APPdates” that we have started to call them.

We have summarized the latest appdates below, if you want to see the webinar you find the recording here. At the bottom of this article, you also find a link to our app home page where you can read more about the apps and use the contact form if you have any questions or feedback to us.

During 2021, EDRMedeso sent out a survey among the users to ask for their feedback on using the apps. The result was encouraging to read as it is a confirmation that we are on the right track providing solutions to the common simulation pains such as “Time to market” and “Human errors” when dealing with complex bolted and welded assemblies that includes code assessment.

“Visualization of results can be helpful to designers and good for presentations for customers.” (Director of Engineering, Aerospace and Automation Engineering Company)

“The hot-spot stress results are dramatically faster to achieve using the app vs. generating without the app.“ (Mechanical Engineer, Material Handling Company)

In the same survey in 2021 we also asked the customers if there are missing features or enhancements they liked to see. We put this list to the backlog for the continuous development of the apps and started working on it.

In the following section we present the “You asked for it, we implemented it” summary!

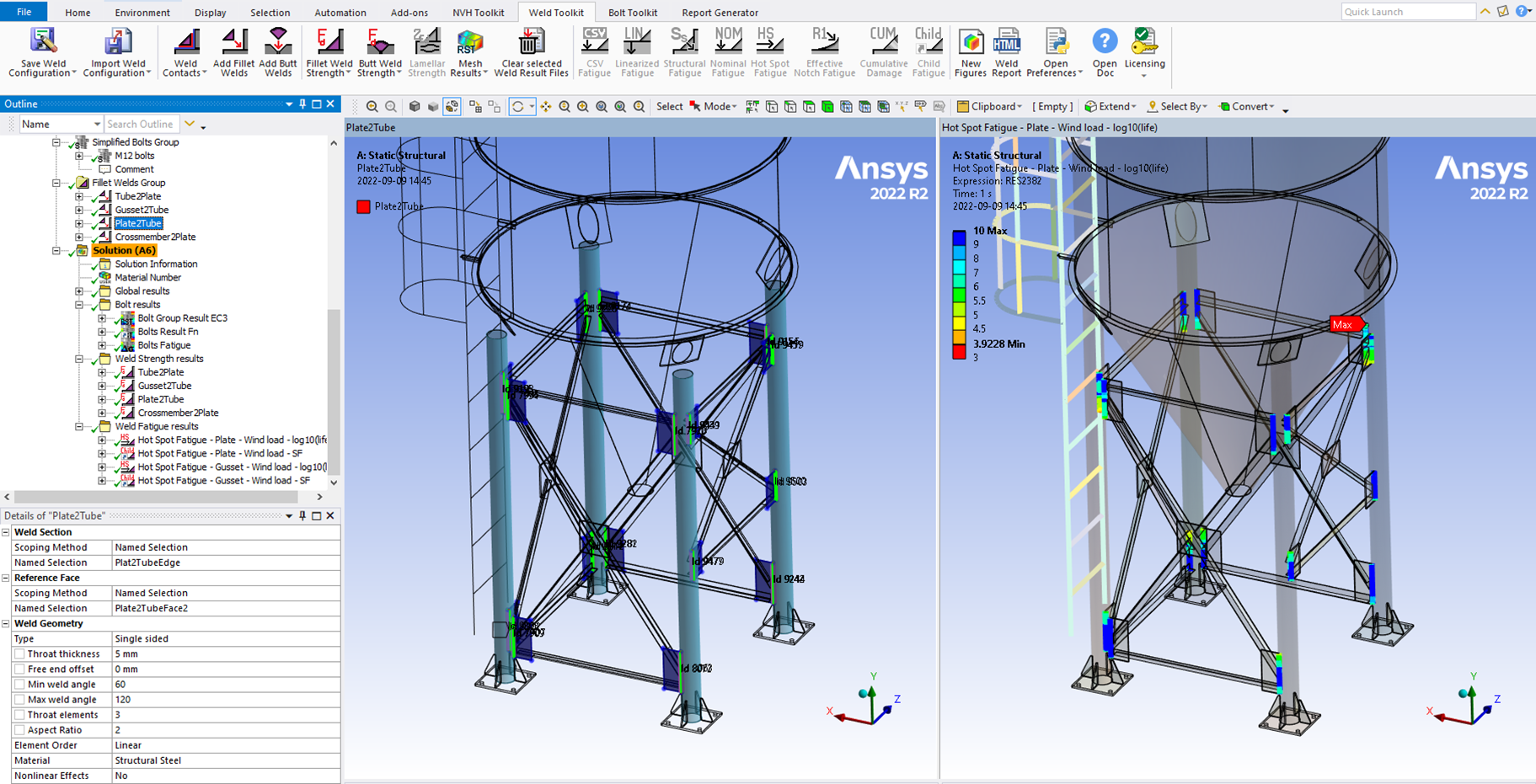

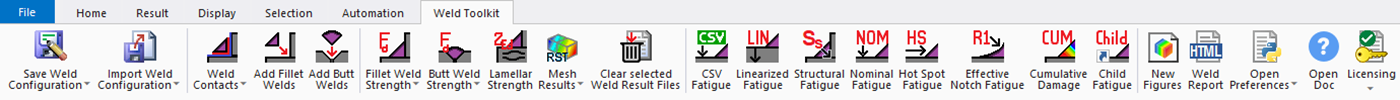

“-A combination of weld fatigue and weld strength toolkits…”

Weld Toolkit is the new common tool for weld strength and fatigue introduced in 2021.

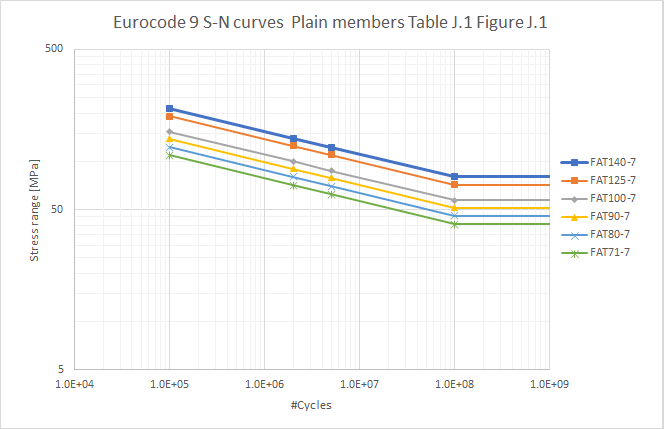

“-More fatigue data would be nice.”

Stress-life curves for aluminum according to Eurocode 9 is added in Weld Toolkit 2022.

User defined S-N curves may be added in the app and saved in the preference file as well.

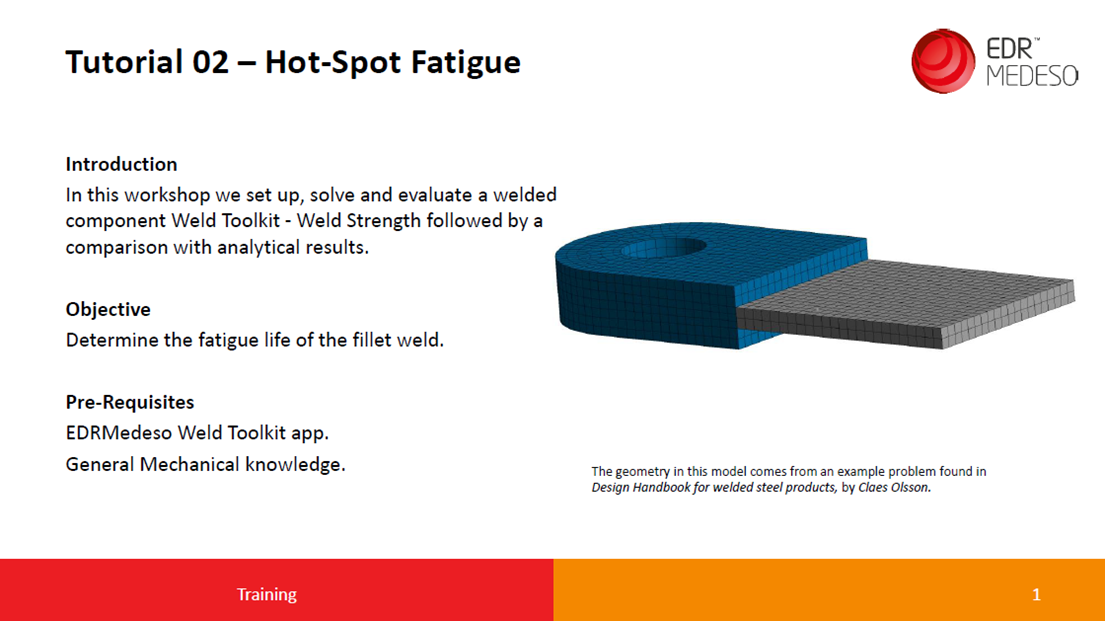

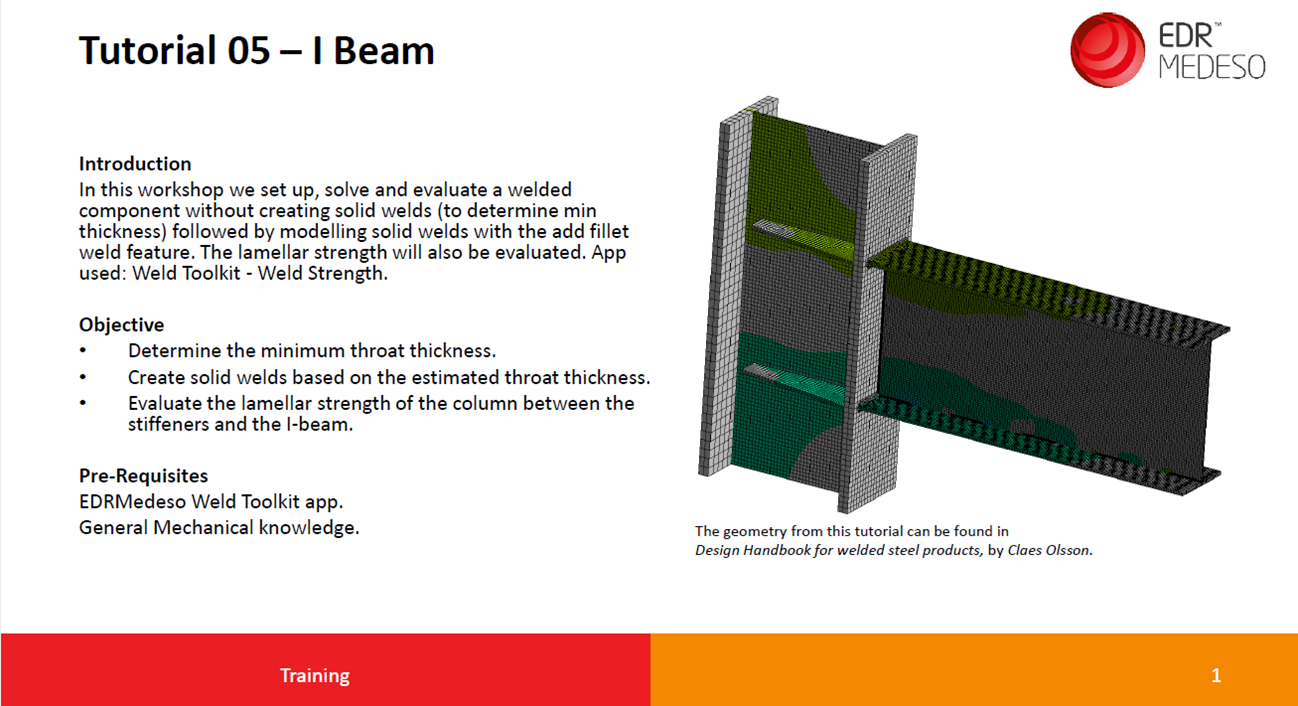

“-…descriptions how to use the existing tools…”

New step by step engineering tutorials for weld strength and fatigue is included with the Weld Toolkit app in 2022. Similar tutorials are also planned for Bolt Toolkit.

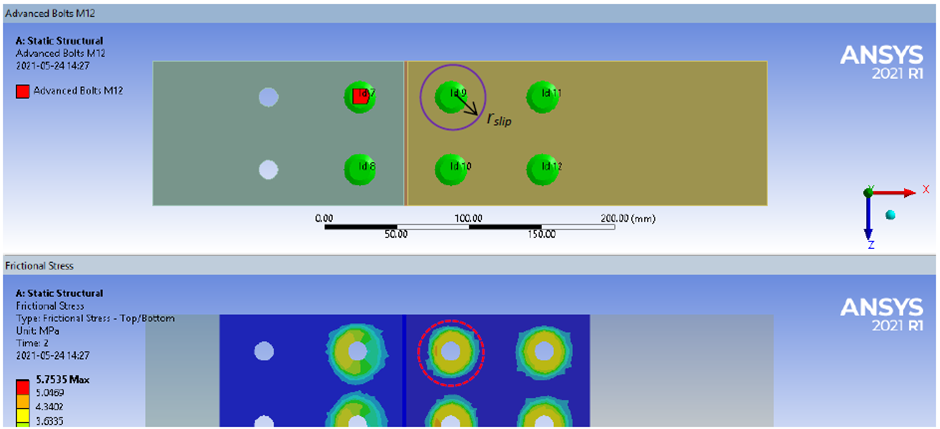

“-Bolt toolkit utilization considers only shear force in bolt (not frictional surface).

Eurocode3 does however not allow for exclusion of these forces.”

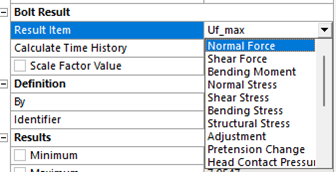

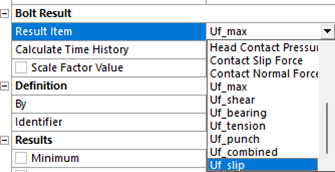

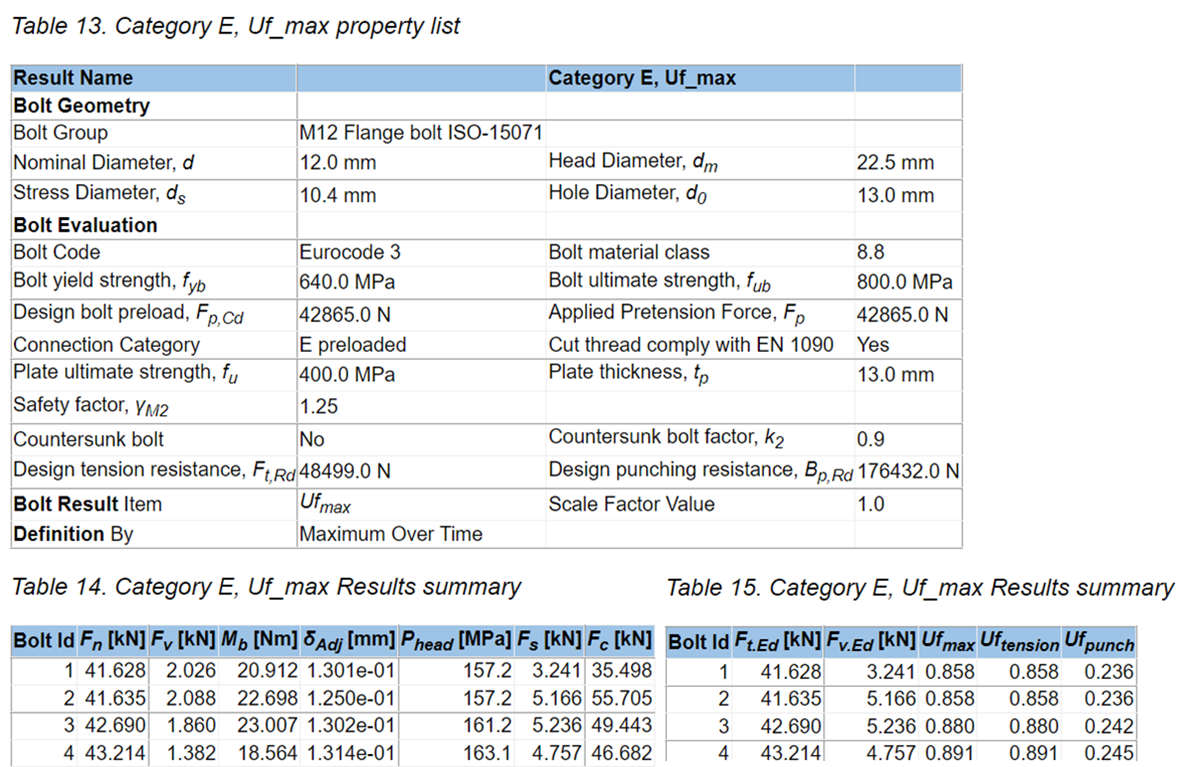

With the recent version of Bolt Toolkit released in 2021 the full Eurocode 3 assessment is now implemented with the different joint categories and all criteria for bolt normal and shear force as well as contact slip and more.

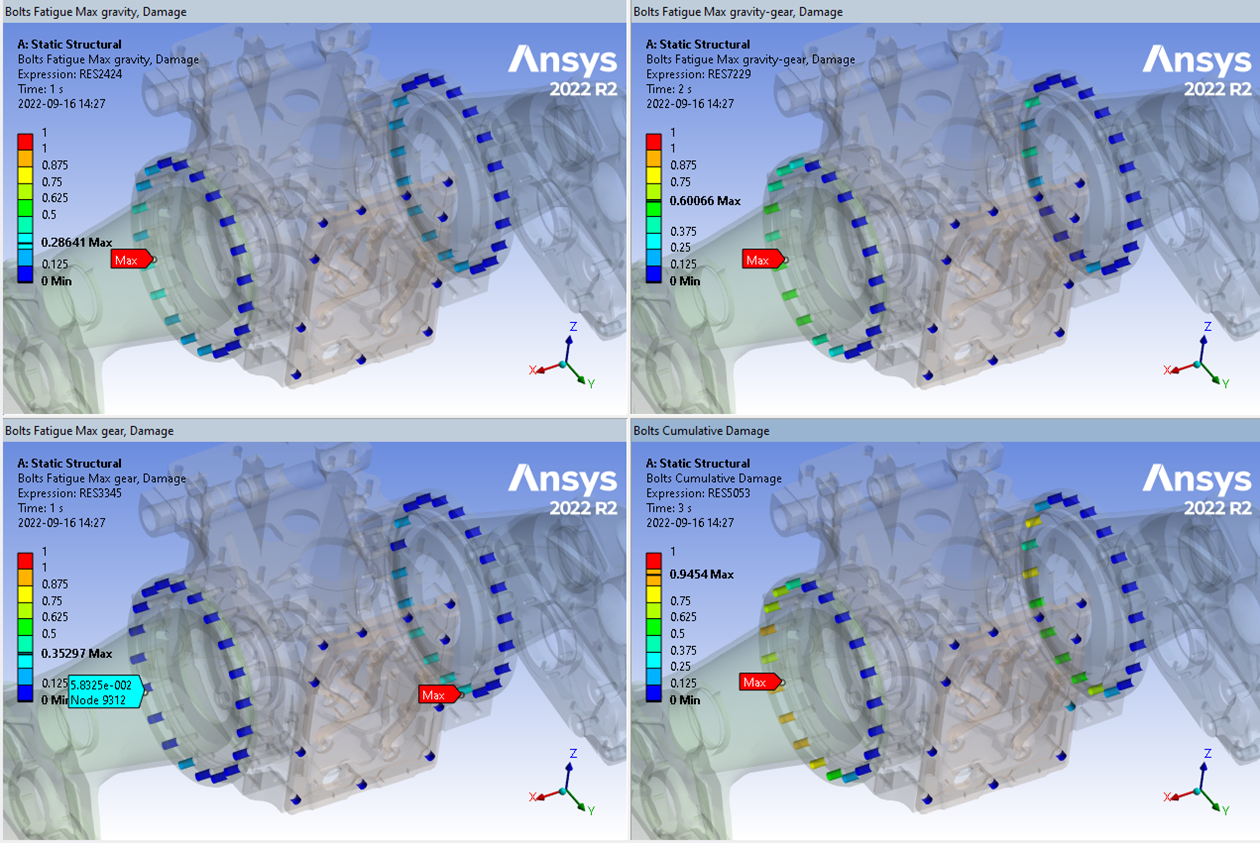

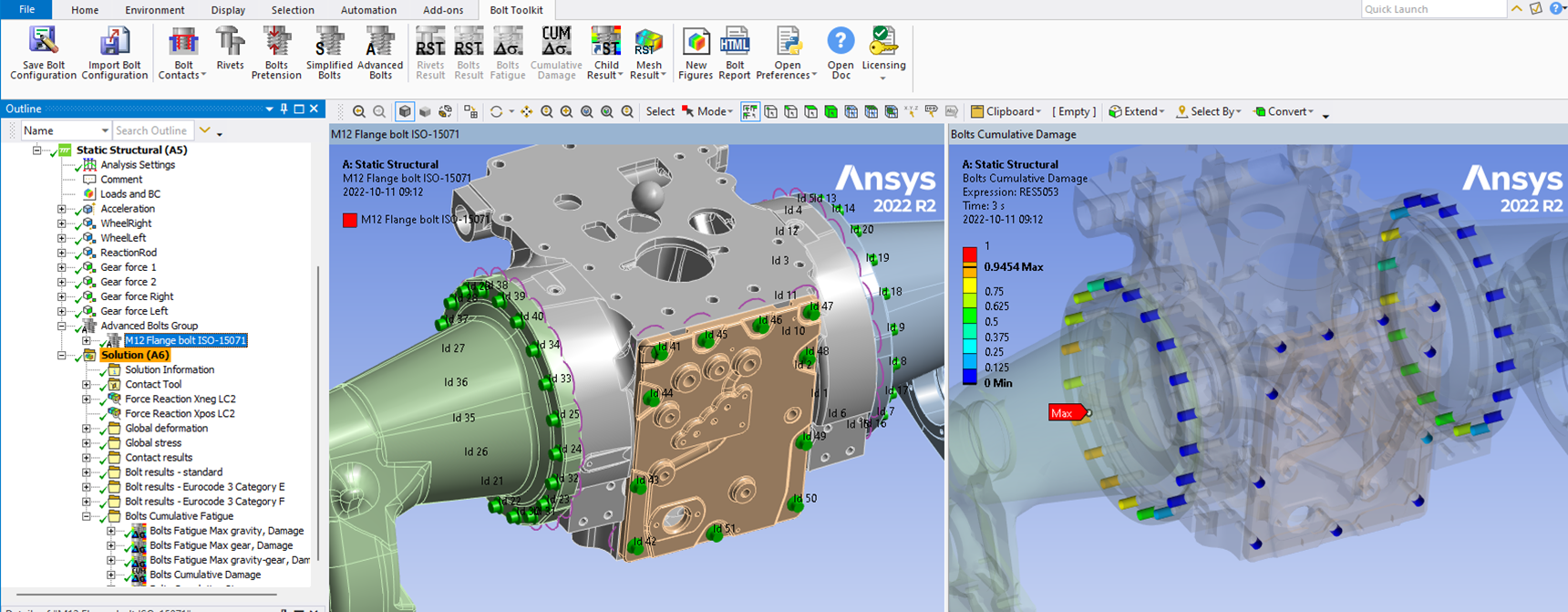

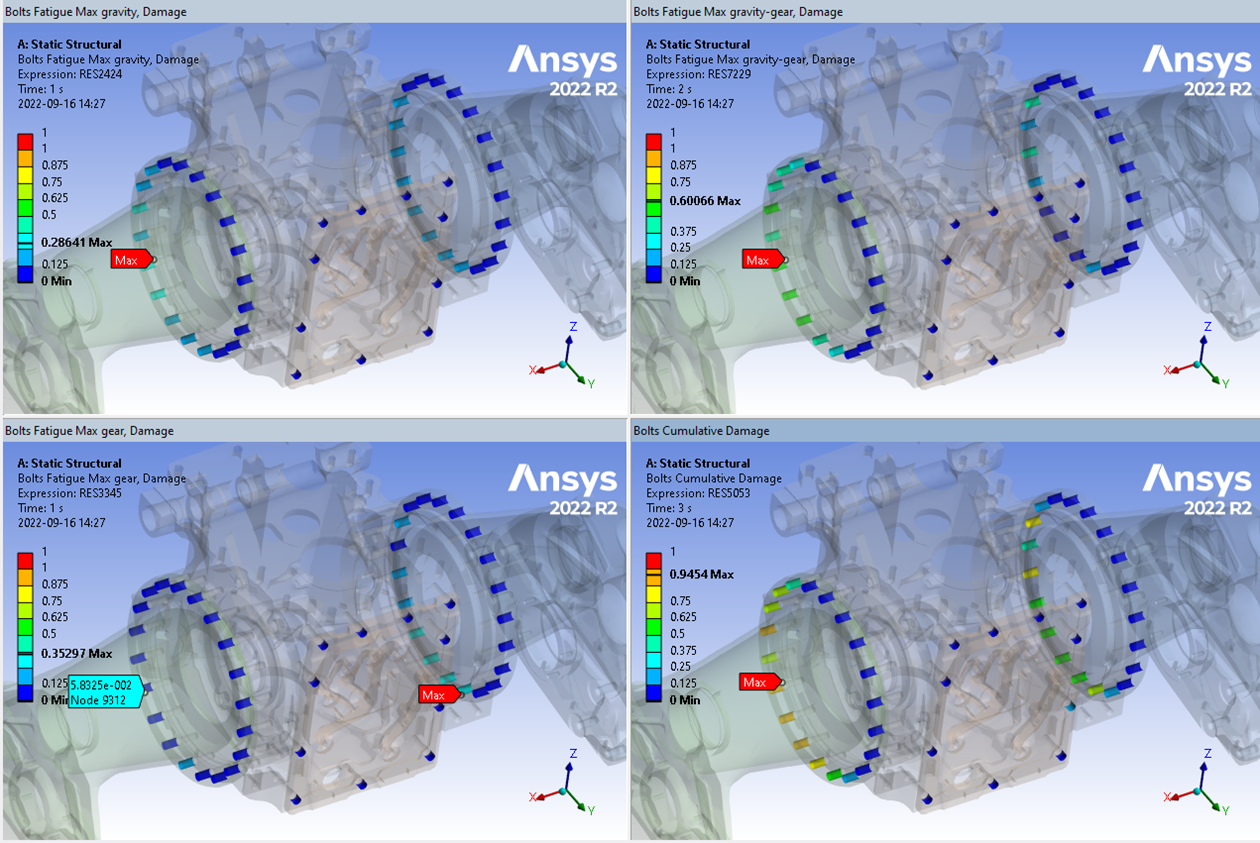

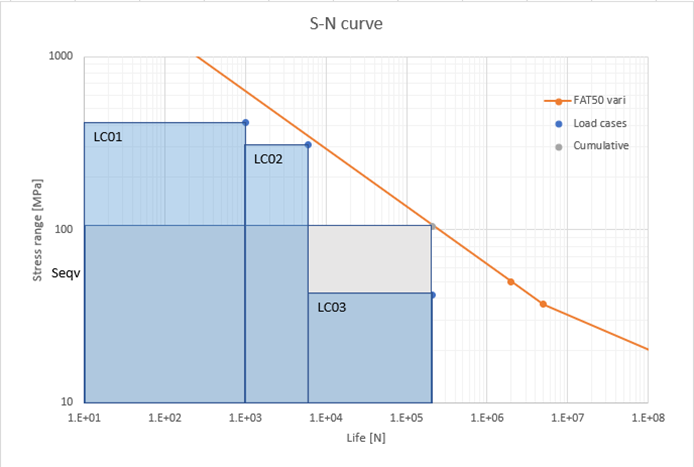

“-Bolt fatigue.”

Bolt fatigue according to Eurocode 3 is implemented in Bolt Toolkit 2022R2 and cumulative damage is coming in 2023R1.

“-I hope that the most recent release of Bolt Toolkit Extension will allow a better postprocessing.”

The post-processing in Bolt Toolkit 2021 was re-made to allow for more result entities in the bolt and contact zones as well as an open API to define user defined criteria.

“-Individual numbering of the items, simple inclusion of only the tabular data of all types of results.”

The post-processing now displays bolt/weld id numbers in the GUI and the automatic report provides easy to read property and result summary tables.

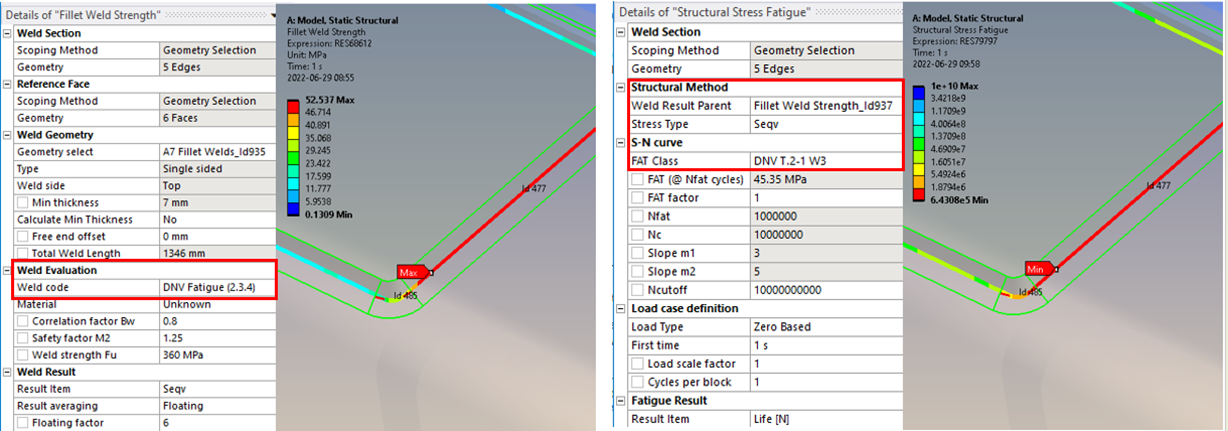

“-Structural stress fatigue of welds.”

Any weld strength result may be used as input for a “structural stress fatigue” result.

The stress type may be an individual stress component, or the “equivalent” stress defined in the weld strength result based on the selected weld code.

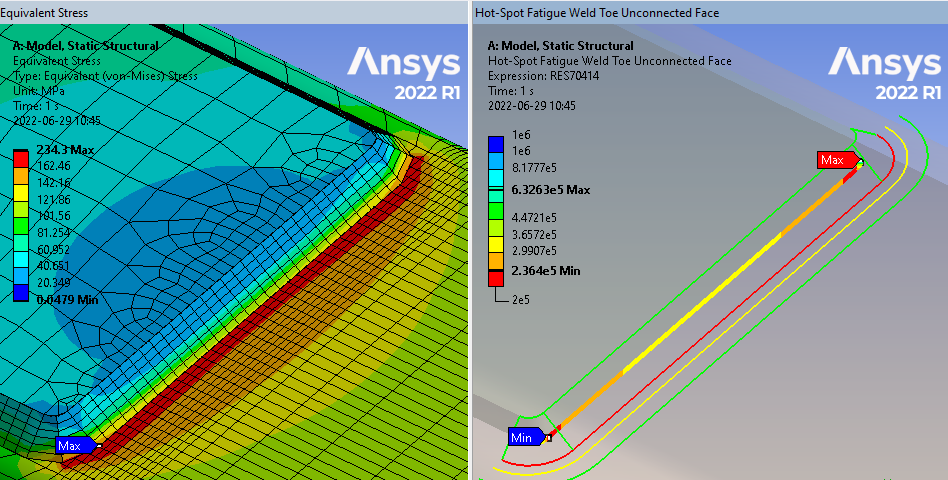

“-Use the hot-spot method in combination with add fillet welds.”

Welds created with the “Add fillet weld” can easily be post processed with the hot-spot fatigue method so that the correct offset is defined by the weld throat size.

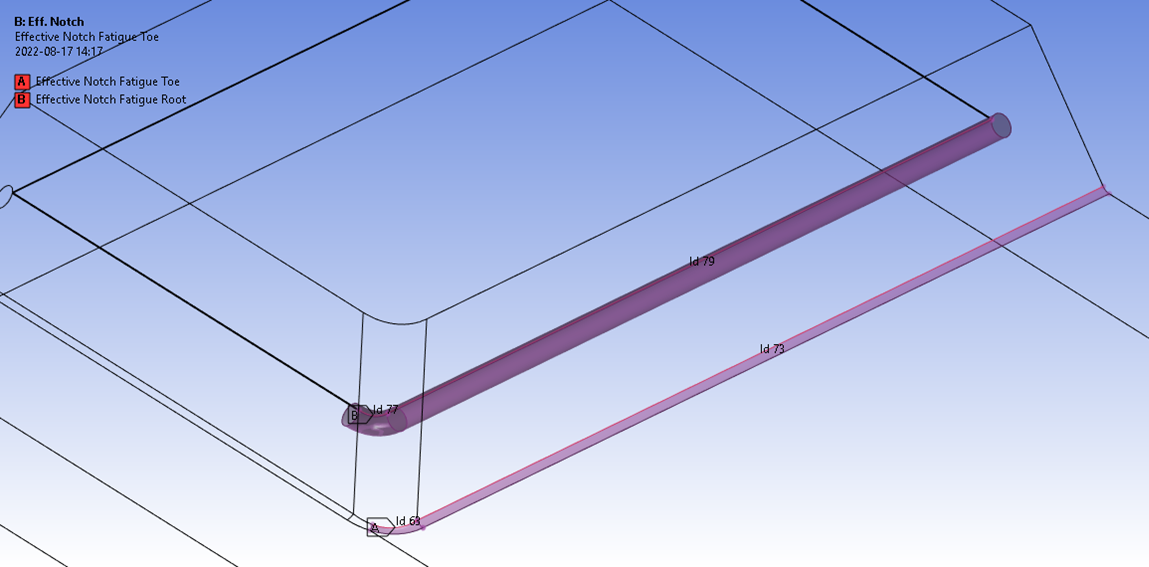

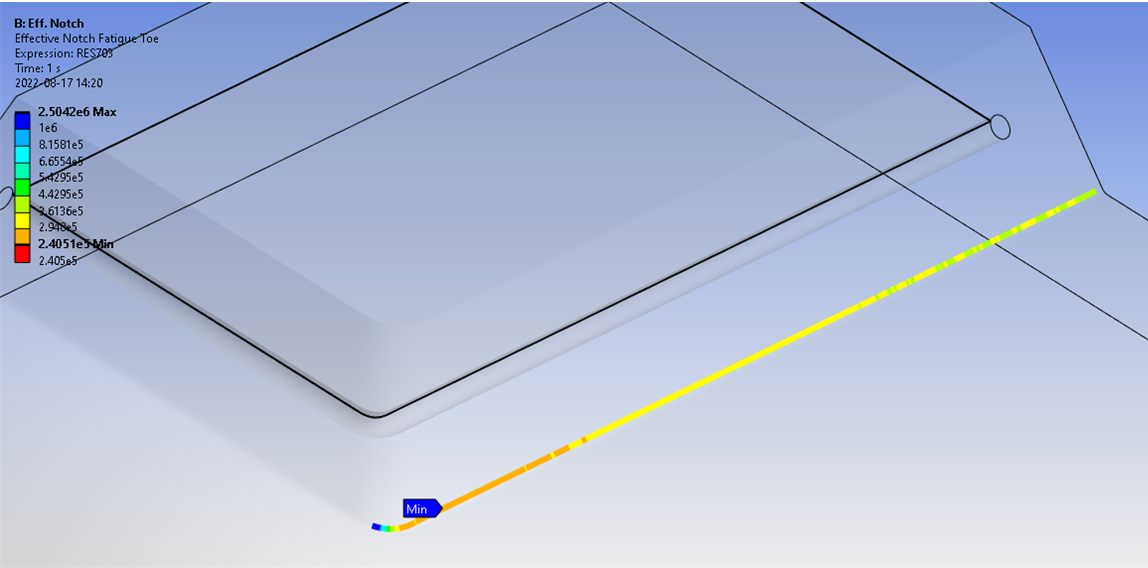

“-Currently it is quite clunky and time consuming to interpret the results of the notch method. … What this causes is a singularity on the cut boundary constraint, and this then pollutes the edges of the notch solution to show extremely low life.”

“Applying the notch method to curved welds.”

The notch fatigue method is improved to use the longitudinal edge along the notch to display the result from the notch. It is also possible to automatically exclude results from (cut) boundary constraints. Other improvements are to use general curved faces and to select stress type (tangential/principal/equivalent) to use.

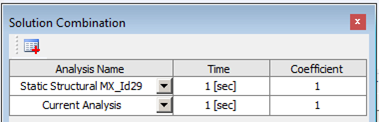

“-Solution combination of different analyses systems”

The solution combination feature in bolt and weld fatigue will be updated in 2023 to allow selecting result steps from any analysis system in the model tree in addition to the “Current Analysis”.

If you already have a license for one or more of the apps, you may use the download link that was provided with the license file to download the latest version or contact our support to get the link.

If you want to learn more or test an app, just fill in the form on the app info page where you will also find the updated feature presentation, EDRMedeso Productivity Apps — EDRMedeso Digital Labs

Frode Halvorsen

Magnus Gustafsson

Fredrika Dahlberg

Video: Recorded Productivity Tools Update webinar from 2022-10-05