Ansys + HEAD Tennis Rackets – by using optiSLang in the design optimization

When HEAD engineers first began using simulation, they evaluated a single design iteration, made changes based on the results and ran a new simulation. It took approximately one week to evaluate the performance of each iteration. The process of design optimization of tennis rackets considers various input parameters.

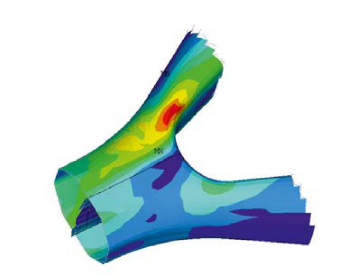

Different fibers, FAWs (Fiber Area Weight), angles and different component compounds and placements yield a large number of possible variations. In addition, a sufficient amount of optimization variables and objective parameters (e.g. stiffness, strength, impact behavior, production costs) are taken into the consideration. This can result in up to 20 million combinations. If one were supposed to build and test a prototype per day, it would take 2,750 years for one million combinations. By conventional means, in real prototyping, such a computational effort for a sufficient number of designs and quality evaluation cannot be realized. The optimization potential remains unused to a large extent.

Today, HEAD engineers frequently use Ansys optiSLang as a nonlinear optimizer to generate design iterations and automatically run Ansys Mechanical simulations in a batch process to identify the optimal solution. Thus, engineers evaluate approximately one million design concepts in about a week to improve the design of a composite structure. The typical goal of an optimization is to find the lightest structure with the highest stiffness and strength that meets other design constraints.

Using optiSLang, large amounts of multidisciplinary nonlinear optimization variables (layer thickness, angle, material…) can be considered and evaluated with different priorities (weight, balance…). The parameterization of layout and geometry is realized in Ansys. Running a sensitivity analysis, optiSLang identifies the relevant input and output parameters, quantifies the forecast quality with the help of the Coefficient of Prognosis (CoP) and chooses the best Metamodel of Optimal Prognosis (MOP).

Based on this identification, the number of design variables are decisively reduced and an efficient optimization can be performed. Thus, a robustness proof of the optimal design as well as the avoidance of over-engineering reliability goals become an integrated part of the optimization procedure.

The ability of prognosis is the key to efficiency. Thus, a “no run too much” philosophy can be implemented minimizing solver runs. Additionally, the evaluation of prognosis allows to distinguish between physical and numerical effects on the change of output variables. For example, it is possible to quantify the influence of meshing if geometry changes.

If permissible limits are violated by scattering output variables, optiSLang safely identifies (statistically provable) the responsible scattering input parameters. The design optimization of the racket does not have to be limited to a few parameters (CAE + CAD) any longer. The full optimization potential can be explored. Furthermore, oversizing is minimized by the implementation of specific variations.

The ability to automatically identify the most important parameters made it possible to analyze such a large number of design alternatives and to optimize performance to a level that would never have been possible in the past. With the help of optiSLang, new design concepts have been frequently identified showing such an improvement compared to traditional engineering practices that the team would never have thought of being applicable.

HEAD has developed a challenging series of quality tests that measure stiffness and strength, which every racket must pass before entering the market. For example, the racket must withstand a drop test onto concrete without any damage. The combination of optiSLang’s stochastic and optimization algorithms with the parameterization and preprocessing capabilities of Ansys Workbench enable engineers to quickly and easily evaluate each proposed design from a quality standpoint, all from the early stages of the product development process.

Simulation and Robust Design Optimization (RDO) have played a significant role in the dramatic improvements that HEAD has achieved in the performance and durability of its tennis rackets over the past decade. The detailed and accurate design information provided by optiSLang and combined with the experience of HEAD engineers has made it possible to produce extremely lightweight designs that can withstand the enormous forces generated by string tension as well as the impact of the ball on the racket during the serve.