Ansys Sherlock – Complete Life Predictions for Electronics Components

Ansys Sherlock provides fast and accurate life predictions for electronic hardware at the component, board and system levels in early design stages. Sherlock bypasses the ‘test-fail-fix-repeat’ cycle by empowering designers to accurately model silicon–metal layers, semiconductor packaging, printed circuit boards (PCBs) and assemblies to predict failure risks due to thermal, mechanical and manufacturing stressors–all before prototype.

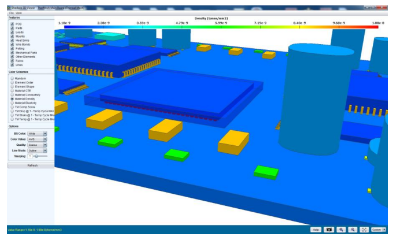

With embedded libraries containing over 300,000+ parts, Sherlock rapidly converts electronic computer-aided design (ECAD) files into computational fluid dynamics (CFD) and finite element analysis (FEA) models. Each model contains accurate geometries and material properties and translates stress information into validated time-to-failure predictions. Sherlock parts databases also include a link to Ansys Granta Materials Selector.

“For each new compressor generation, we need to redesign a PCB. So, we start from zero, but we re-use our experience. Sherlock allows us to arrive at a robust design faster, with less trial-and-error iteration.” – The Sanden Group

The Sanden Group is a Tier 1 automotive supplier of air conditioning compressors based in Japan and has locations worldwide. In 2020, Sanden Manufacturing Europe decided to test Ansys Sherlock automated design analysis software to analyze printed circuit boards (PCBs) for its electrical compressors. Using Ansys Sherlock, Sanden cut model creation time from 7 days to 1.