Ansys Will Transform Metal Stamping Through Launch of Ansys Forming

Ansys Will Transform Metal Stamping Through Launch of Ansys Forming

Powered by the LS-DYNA solver, Ansys Forming offers a comprehensive platform to meet all your metal stamping needs. Able to monitor each stage with presets, including feasibility, formability, and springback, Ansys Forming advances early stage and detailed design configurations.

Ansys will release its first metal stamping simulation software in 2022, an all-inclusive product equipped to meet industry needs within one platform. With Ansys LS-DYNA as its solver, Ansys Forming provides predictive accuracy and a streamlined workflow to digitally design, simulate, and validate sheet metal forming throughout the metal manufacturing process.

Ansys Forming enables early stage and detailed design configurations by allowing users to preset varying simulation needs, including feasibility, formability and spring back prediction. Through this end-to-end workflow, engineers can perform the entire die process on a single platform, eliminate the need for physical testing, and enhance productivity and cost savings. Ansys Forming reaches optimum performance by maintaining predictive accuracy and speed.

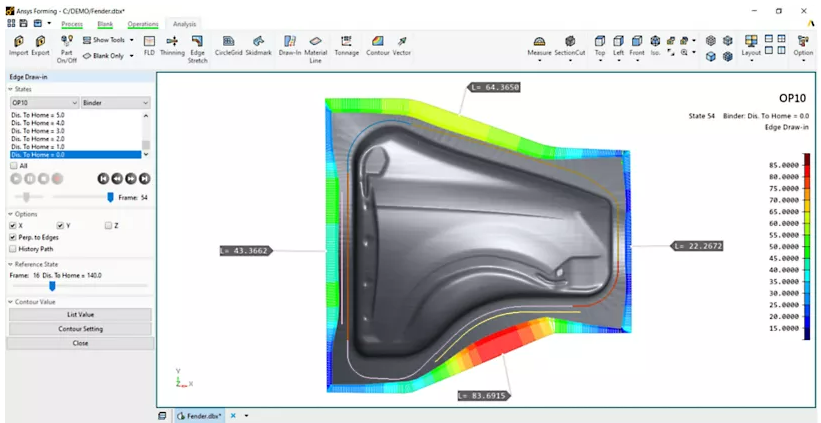

Material flow at the edge of the sheet metal for the fender of an automobile

“Ansys Forming is intuitive, efficient and allows our team to set up complicated forming processes in a short period of time,” said Xue Fei Green, technical director, Dongguan Vision Tool & Mould Co., Ltd. “Ansys Forming combines pre- and post-processing in one package and removes a lot of the manual work required by its predecessors. I’ve used many and am confident that Ansys Forming is the best pre- and post-processor for metal forming applications.”

Sheet metal forming simulation helps manufacturers detect errors, identify the most appropriate materials, and determine the most efficient and cost-effective machining process to use. As a result, engineers spend less time designing and redesigning later. Additionally, Ansys Forming delivers a tremendous detail about the design, including identifying structural weaknesses where the metal might wrinkle, tear, or buckle.

“Ansys Forming will enhance our customers’ simulation processes and lower the barrier to entry for engineers, because the interface is so easy to use,” said Ramesh Venkatesan, CEO at Kaizenat. “The increased accessibility and improved workflow will take our users cost savings to the next level.” Kaizenat is a certified Ansys channel partner.

Ansys Forming product developers are already working toward future releases with additional functionalities, including a springback compensation feature.

“Ansys Forming will meet the metal stamping needs of the industry, from the biggest manufacturers and suppliers to the smallest die shops,” said Shane Emswiler, senior vice president of products at Ansys. “With all-in-one stamping software, manufacturing and process engineers will streamline their workflows, increase productivity, and achieve consistent solutions every time.”