Are EDRMedeso Productivity Tools for Me?

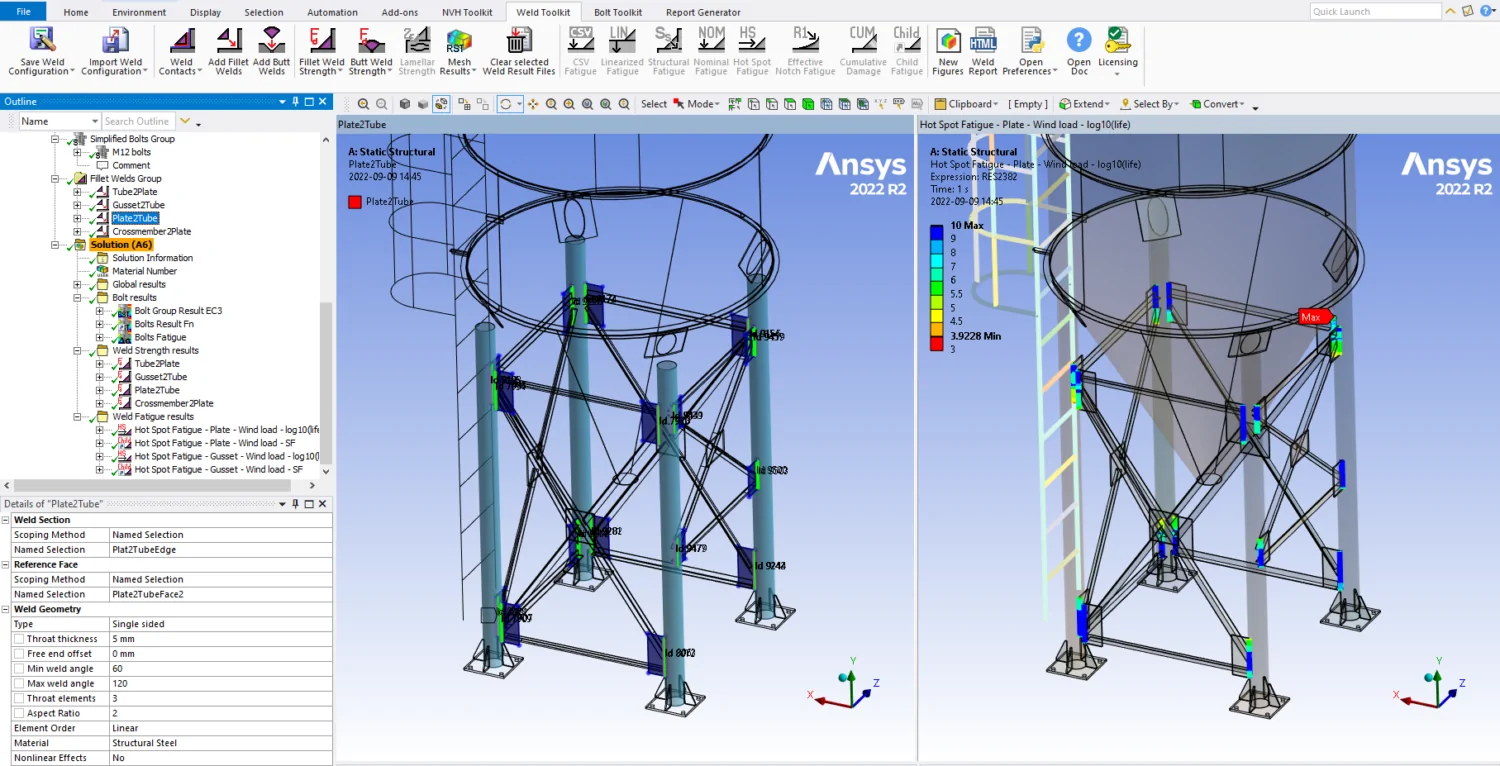

If more than one person is carrying out bolt/weld analysis the risk of human error and diversified team increases. The Bolt/Weld Toolkit can democratize complex post processing from a simulation specialist to every simulation engineer using Ansys Mechanical.

The more time that’s spent on repetitive, manual work, the more opportunity there is for human error. Dealing with hundreds of bolts/welds in combination with multiple load cases creates a huge administrative challenge and adds complexity when it comes to achieving a succinct overview of results.

The toolkits positively address both administrative and visualization aspects as well as increase the evaluation speed from multiple hours – or days – down to minutes, allowing more time for development and optimization. The cost of one Bolt/Weld Toolkit lease license is equivalent to two weeks of engineering hours (~50€/h).

Over-designing is a simple but expensive solution when just validating the final design. The toolkits will instead allow you to iterate the sizing, material and placements of bolt/welds as a simple load feature instead of making a geometry change and update the model setup.

Missing to do evaluations of all possible load case combinations as well as overdesign can cause strength/fatigue failure. Missing or poor documentation makes identifying and solving the issue harder.

The toolkits can evaluate and combine results from different shared analyses of operations and evaluate the worst-case results for all bolt/weld groups at once.

The dedicated bolt/weld report features provide detailed summaries of the inputs such as design values and tables of utilization and stress details for all items.

Evaluating welds according to a design code is especially difficult due to the requirement to extract stresses or forces in local coordinate systems aligned with the welds and then combine the different stress items to calculate the utilization.

The toolkits keep track of the orientation automatically based on the selected geometry. The utilization is based on the design resistance and design stresses are then automatically derived. The included design codes in the toolkits can also be modified to adopt to user defined codes using the dedicated “Settings” feature in the app.

Bolt/weld code assessment is challenging and quite often inappropriate to assign to junior engineers. The apps provide a common and well-defined way of working directly inside Mechanical, no need to learn a different user interface, manage external files, or fill in Excel sheets.

Reporting can be used to track decision making. If a report is missing, design decisions are made on vague criteria and a sub-optimal solution may be selected.

The Report Generator makes it very easy to extract the relevant model information and result details to an html or Microsoft Word report where the included Word template can be customized according to your company template.

Report writing may be low priority due to new urgent projects. Time saved in writing reports is better used in development. A basic report with Report Generator can be completed in 1 hour and updated in 1 minute compared to several hours to days manually.

Making comparisons between reports of different projects and users may be difficult. Using an old report and using copy/paste is fast but can introduce errors. Report Generator extracts the information from the model directly.

Extracting consistent report data and formats for all model information can be tedious. The apps provide a common and well-defined way of working directly inside Mechanical, no need to learn a different user interface or manage external files or Excel sheets. Results from both Bolt Toolkit and Weld Toolkit are automatically included in the report.