Defining Digital Twin

Well, what is it?

The beginning of wisdom is the definition of terms is a saying attributed to Socrates. There are some disputes to whether Socrates actually said this or not, but it still might be a good idea to start defining the term Digital Twin.

In literature, the term was first found in the paper Virtually Perfect: Driving Innovative and Lean Products through Product Lifecycle Management by Michael Grieves in 2011. No published literature had used the term before that, but several systems had already been made that could fit the definition. The term was later used and popularized by NASA, and today there exist dozens of definitions on the web. The problem is, however, that they all differ slightly.

Its not hard to imagine how multiple definitions of the same term have led to miscommunications and confusion. To harmonize the understanding, a consortium of experts were established, with the aim to make a single best practice definition of Digital Twin. On December 3, 2020, the Consortium released the following definition:

A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity.

Digital twin systems transform business by accelerating holistic understanding, optimal decision-making, and effective action.

Digital twins use real-time and historical data to represent the past and present and simulate predicted futures.

Digital twins are motivated by outcomes, tailored to use cases, powered by integration, built on data, guided by domain knowledge, and implemented in IT/OT systems.

A further expand on the terms used in the definition can be found here.

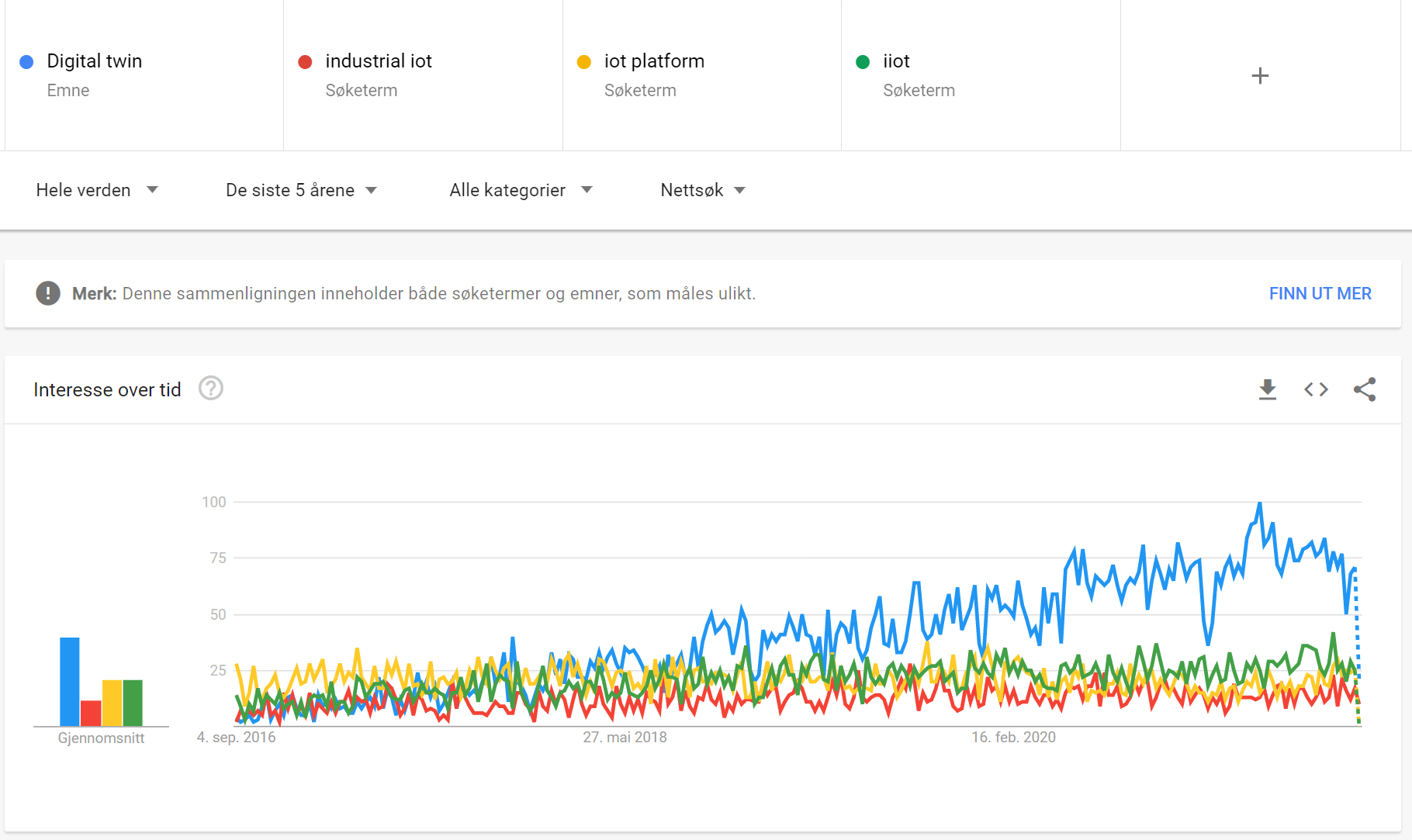

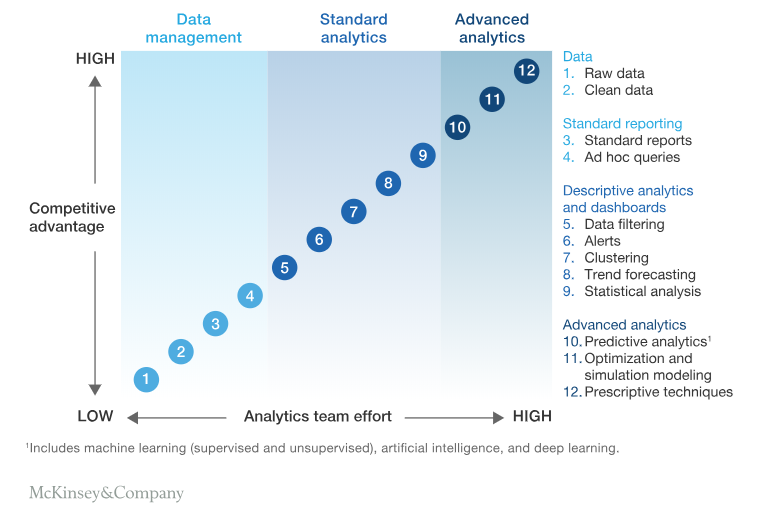

Another way to define Digital Twin, is to look at it as a spectrum, as McKinsey has proposed. Maybe there are so many different definitions of Digital Twin because what they try to define actually are different?

McKinsey has differentiated Digital Twin into twelve subcategories; from simple twins that only gives simple output, to advanced twin that give high-value competitive output. Correspondingly, the high-value twins require a high team effort to make.

The plot from McKinsey differentiates Digital Twins by their level of competitive advantage. This is an important distinction, since there is a big difference between a Digital Twin that only carries information, to a Digital Twin with advanced analytics that performs multi-physical simulations or machine learning. An example of the first could be Digital Twins used in a BIM context, where the digital twin could be a linked, updated as-build model of a building. An example of the latter could be a digital twin of a hydropower turbine that suggest an optimum input flow rate based on all relevant parameters like electricity price, water in dam and estimated damage on the turbine for different flow rates.

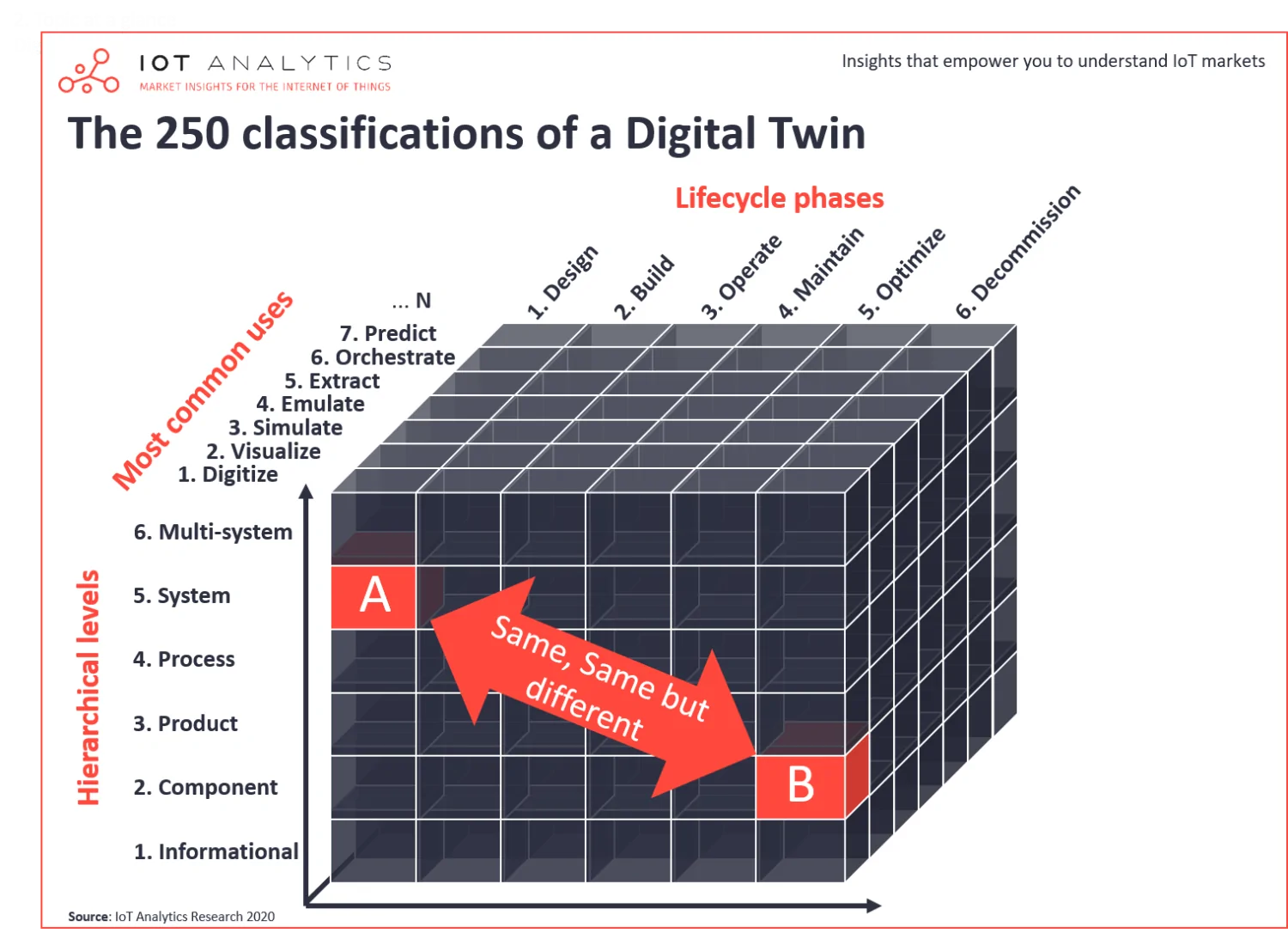

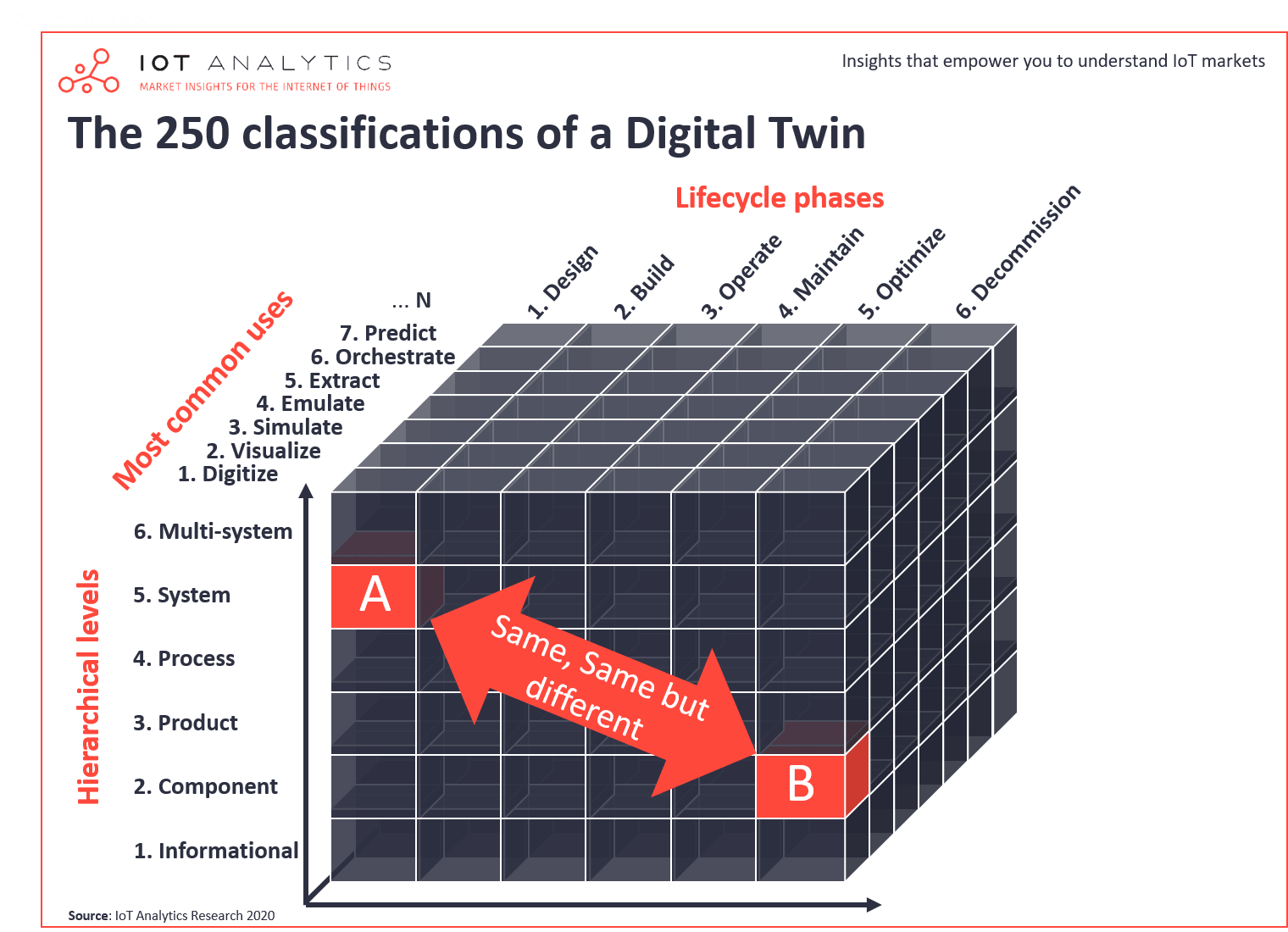

While competitive advantage is an important differentiator, other parameters are influential as well. In a 90-page insight report, a company called IoT Analytics revealed the results from a in-depth study on the topic. They conclude that there are three dimensions that are especially important when distinguishing Digital Twins from each other. These dimensions are:

The hierarchical level the Digital Twin is applied to (6 levels identified)

The lifecycle phase in which the Digital Twin is used (6 phases identified)

The use of the Digital Twin (7 most common uses identified)

From these dimensions, one could make the following visualization, containing 252 potential combinations of digital twins (6x6x7=252).

The fourth way to look at Digital Twins, is to see it in light of Industry 4.0. Industry 4.0, or the fourth industrial revolution, as it is also called, is the ongoing automation of traditional manufacturing and industrial practices, using modern smart technology. Large-scale machine-to-machine communication (M2M) and the internet of things (IoT) are integrated for increased automation. In this context, digital twin can be defined as a subset of Industry 4.0, containing the processes that contains linked, virtual copies of real-world entities.

This way of looking at Digital twin is less precise, but it encompasses an important fact: That Digital Twin is not something new, but rather a part of the natural development in the industry.

Depending on which definition of digital twin one prefers, common factors are always that they are linked, virtual copies of real-world entities.

And while the terminology Digital Twin is rather new, there are several older instances of what we would today call digital twins. It can be argued that NASA had their own digital twin as early as 1970 with Apollo-13. Data from connected sensors were crucial for the survival of the three American astronauts that were on the very brink of disaster in deep space.

Since then, increase computation power, cheap sensors and advanced analytics have increased the potential exponentially. Much work remains to be done, but having common terminology is important in the making of digital twin platforms, disruptive business models and digital twin ecosystems.

Do you want to know more about digital twins? Check out the Digital Twin Training Course I will be teaching in Oslo at October 28th and 29th, 2021

Published by Håkon Bull Hove at EDRMedeso