Driving Down Time to Market

anfoss A/S uses ANSYS Sherlock automated design analysis software to predict solder fatigue in virtual prototypes of its new AC drive designs.

Danfoss drives are compatible with all shown motor types.

More than 50% of the world’s electrical energy goes into powering the electric motors that spin up everything from simple compressors in HVAC to high-precision positioning and synchronization operations in the food and beverage industry. AC drives control the speed of these motors, so bringing more efficient AC drives to market is critical to improving energy efficiency. Danfoss A/S, one of the world’s largest manufacturers of AC drives, is dramatically reducing time to market for its new AC drives using ANSYS Sherlock.

The world turns on electric motors. They power everything from subway wheels to big turbines, from escalators to baggage carousels. With so many uses, electric motors are often required to operate at varying speeds and torque levels to suit application demand. For example, when there are few or no bags on the carousel at the airport, there is no need for the carousel motor to spin at its top-rated speed or torque and waste electricity.

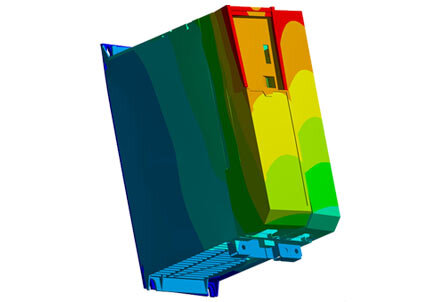

Deformation of a printed circuit board assembly and components inside a drive using ANSYS Mechanical. Red represents maximum displacement and blue represents minimum displacement.

With so much of the world’s electrical energy being used by electric motors, anything that more effectively regulates power to them helps reduce energy waste. That is where AC drives from Danfoss A/S come into play. AC drives — also known as adjustable or variable speed drives, variable frequency drives, frequency converters, inverters and power converters — control the speed of electrical motors. Danfoss drives play a key role in the development of smart communities by helping to deliver an uninterrupted, temperature-controlled supply chain, a fresh food supply, building comfort, clean water and environmental protection. In all, the company’s line of AC drives has thousands of variants to cover the widest range of applications from a fraction of a watt to several megawatts. Engineers in its R&D facilities — in the United States, Germany, India and China, as well as in the company’s headquarters in Graasten, Denmark — work constantly to bring new and more advanced AC drives to market.

The product development cycle for a new AC drive can stretch out several years. Danfoss engineers wanted to explore ways to bring new products to market faster, which led them to ANSYS Sherlock automated design analysis software.