Engineering Sustainability – A Guide

Sustainability initiatives are prominently featured on many corporate websites, especially among larger companies. This high-profile focus is largely driven by legislation, such as the European Union’s Corporate Sustainability Reporting Directive (CSRD), which mandates that companies report on their environmental footprints and commit to science-based reductions in CO2 emissions. Companies exporting to the EU must comply with these regulations, which also emphasize circularity and the end-of-life reuse of products.

One of the primary challenges in achieving sustainability is the limited availability of data on the environmental impact of materials. Companies need to consider several factors when selecting materials, including cost, weight, and performance. Without comprehensive data, making informed decisions is difficult, and changes made late in the design process can be costly and time-consuming.

Companies often struggle to find reliable data on the sustainability of different materials. This lack of information makes it challenging to compare materials and make informed choices that balance performance, cost, and environmental impact.

Traditionally, environmental assessments are conducted late in the design process, when most decisions have already been made. Making changes at this stage can be prohibitively expensive and may require significant rework.

Sustainable design is not just about choosing the greenest material. Engineers must also consider factors like cost, weight, performance, and regulatory compliance, making the decision-making process complex and multifaceted.

Companies typically approach sustainability at two levels: corporate and engineering. At the corporate level, strategies include using materials with higher recycled content, sourcing from suppliers with lower

CO2 footprints, utilizing green energy, and reducing packaging. These changes can be implemented without altering product designs, offering a quick way to improve sustainability.

However, for significant impact, sustainability must be considered at the engineering level. This involves designing products with sustainability in mind from the outset, balancing environmental impact with performance and cost. This proactive approach allows for material and design changes early in the development process, optimizing the product for sustainability.

Over 80% of a product’s environmental impact is determined at the design stage. Early consideration of sustainability allows for material and design optimizations that significantly reduce the carbon footprint. By integrating sustainability into the design process, companies can achieve substantial environmental benefits and move closer to their net-zero goals.

Ansys and its Granta products focus on the engineering level, providing tools and data to support sustainable design. Key components of Ansys’ solutions include:

Material Universe Dataset: offers extensive reference data on materials, including sustainability metrics. This dataset helps engineers understand the environmental impact of different materials and make informed choices early in the design process.

Advanced Materials Eco Data: provides detailed information on the environmental impact of materials, supplementing company-specific data. This dataset includes information on factors such as CO2 footprint, recyclability, and toxicity, enabling a comprehensive assessment of material options.

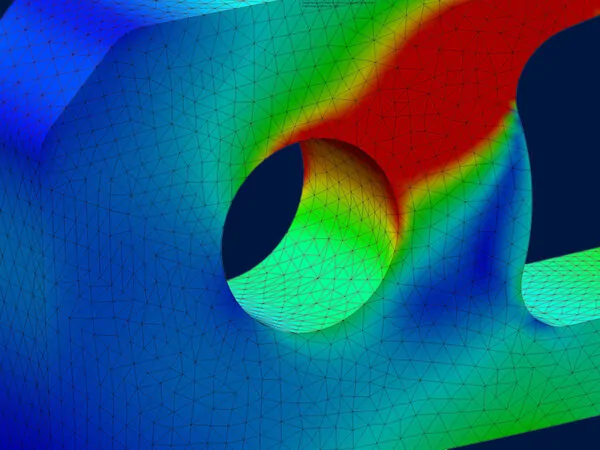

Granta Selector: helps engineers evaluate alternative materials early in the design process, balancing sustainability with performance and cost. The tool enables rapid comparison of materials, allowing engineers to identify the best options for their specific applications.

Eco Audit Tool: enables quick assessment of a product’s environmental footprint, facilitating early-stage design changes that have significant sustainability impacts. By providing insights into the environmental performance of different materials and design choices, the Eco Audit Tool helps engineers optimize their products for sustainability.

Ansys tools integrate seamlessly with CAD, CAE, and PLM systems, allowing engineers to access sustainability data within their native environments. This integration ensures that sustainability considerations are incorporated into the design process from the very beginning.

Simulation tools like Ansys Discovery and OptiSLang optimize designs for both performance and sustainability, enabling detailed analysis and refinement. These tools allow engineers to explore different design scenarios and identify the best solutions for minimizing environmental impact while maintaining high performance.

Designing for sustainability involves considering environmental impact at every stage of the product development process. By choosing materials and design strategies that minimize environmental impact from the outset, companies can create products that are both high-performing and eco-friendly.

Sustainable design requires a holistic approach that balances environmental impact with other important criteria such as cost, weight, and performance. Advanced simulation tools help engineers evaluate these trade-offs and make informed decisions that optimize all aspects of the product.

Sustainable product design requires a comprehensive approach that includes both corporate-level strategies and detailed engineering considerations. Ansys provides the tools and data necessary to make informed decisions, enabling companies to design products that are not only high-performing but also environmentally friendly. As regulations continue to evolve, the ability to proactively address sustainability at the design stage will be crucial for companies aiming to lead in the green economy.

Download our ‘5 Steps to Eco Design’ whitepaper