Making Python Do the Heavy Lifting: How PyAnsys Unlocks Engineering Simulation at Scale

Simulation today isn’t just about proving that a design will work. It’s about integrating simulation into every part of the product lifecycle, from early ideation to late-stage validation, and even through operation and service. Engineers, designers, and analysts now expect their simulation tools to be flexible, fast, scalable, and most of all, automated.

If you’ve ever spent hours clicking through GUI menus in a simulation environment, you know the frustration. You repeat the same steps with slight variations, hoping nothing breaks or gets missed. What if you could automate all of that?

PyAnsys is the bridge that makes this possible. It’s not a new solver, not a replacement for Ansys Mechanical or Fluent or HFSS, it’s a control layer, a Python-based suite of libraries that lets you take command of your simulation workflows, customize them, scale them, and make them your own.

Python has become the ‘de facto’ language of automation, machine learning, data science, and cloud-native development. It’s easy to learn, ridiculously flexible, and has a massive ecosystem. PyAnsys leverages this power and brings it to the world of engineering simulation.

Instead of clicking through interfaces to set up boundary conditions, mesh controls, and solve settings, you can write clear, readable Python scripts. Want to simulate a bolt tightening with different torque values? Write a loop. Want to generate hundreds of mesh variations? Automate it. Want to post-process simulation results and instantly build plots and dashboards? Python’s data tools like NumPy, Pandas, and Matplotlib are readily available.

The shift from GUI to script isn’t just about convenience but about power. With scripting, you can create workflows that are version-controlled, shareable, repeatable, and integrated with the rest of your engineering stack.

PyAnsys isn’t one monolithic library. It’s a collection of purpose-built packages that interface with various Ansys solvers and tools. For example:

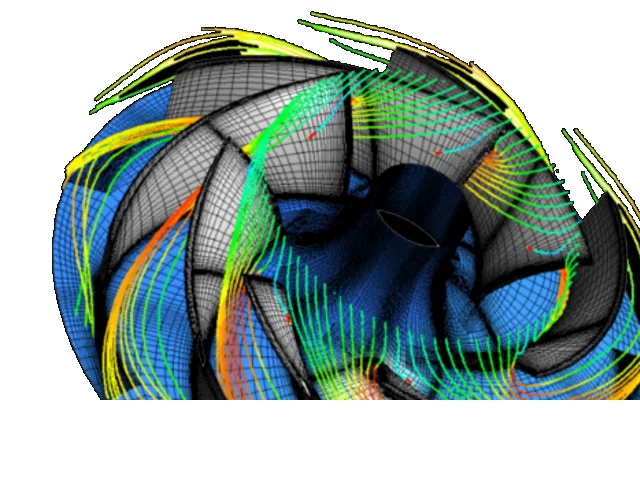

These tools are built to work in tandem. Imagine simulating structural deformation in Mechanical, passing the results into a thermal model in Fluent, and then visualizing everything in a Python dashboard……this is game-changing!

One of the biggest bottlenecks in simulation is scale. Running one model is fine. Running a hundred variants is where things break, unless you automate.

PyAnsys lets you scale your simulation workflows horizontally. You can parallelize studies, orchestrate cloud-based resources, and run optimization loops that explore design space faster than any manual process could. With tools like Docker and Kubernetes, PyAnsys workflows can be containerized and deployed at enterprise scale. Combine that with version control tools like Git, and you get traceable, repeatable simulation pipelines.

If you need to tweak the design of a battery enclosure across 500 permutations all that’s required is to write the parametric logic once, loop through variables, and spin up your runs across multiple nodes. This isn’t just faster, it’s better. It ensures consistency, reduces human error, and frees up engineering time for more strategic work.

Notebooks have become a popular tool in engineering and data science. With PyAnsys, your entire simulation workflow from model definition to visualization, can live in a notebook. That means clearer documentation, easier collaboration, and a faster feedback loop.

If you want to share results with a product manager or design team a notebook can easily be turned into an interactive dashboard using tools like Dash or Streamlit. If you want to plug your simulation into a larger machine learning pipeline you’re already in Python so it’s easy to jump to TensorFlow, scikit-learn, or any other library right alongside your simulation logic.

In short, PyAnsys doesn’t just automate, it integrates. It lets simulation be part of the broader digital product development ecosystem, not a siloed afterthought.

The following example is indicative of the what a PyAnsys-driven workflow might look like. As an example, you’re designing a new electric motor housing. You need to analyze its structural integrity under various thermal loads and vibration conditions. Here’s a PyAnsys Geometry generation, automated via parametric CAD or Python-based geometry tools:

This entire process might run overnight across multiple cores or cloud machines. In the morning, you’ve got results, comparisons, plots, and a shortlist of best candidates.

PyAnsys is open source and actively maintained by Ansys and the simulation community. That’s important. It means you can explore, adapt, and contribute. It also means that the tools will evolve with the needs of real engineers, not just product managers.

There’s transparency in how things work. Documentation is publicly available. Examples are shared and searchable. And because it’s Python, it plays well with the broader open-source world from SciPy to PyVista to Paraview integrations.

Startups love it because it’s lightweight and fast. Enterprises love it because it scales. Researchers love it because it’s flexible. And consultants love it because it saves time.

Whether you’re running a consultancy doing custom simulation workflows, or you’re an in-house engineer looking to automate repetitive setup tasks, PyAnsys offers faster, smarter ways to get results.

And as industry is moving toward simulation-driven design, it means simulation isn’t a final check. It’s baked into the design loop from day one. With tools like PyAnsys, that vision becomes reality. You can run real-time analysis alongside design changes, feed simulation results into generative design tools, or even train AI models based on simulation outputs.

The gap between design, simulation, and production is shrinking. PyAnsys is the connective tissue that makes that convergence not only possible but practical.

You don’t need to be a Python expert to begin. The PyAnsys libraries are well-documented, with plenty of examples. Start with something simple: automate a single task you currently do manually. Add post-processing to an old model. Build a loop for a parametric sweep.

As you grow in confidence, you’ll realize there’s almost no limit to what you can script.