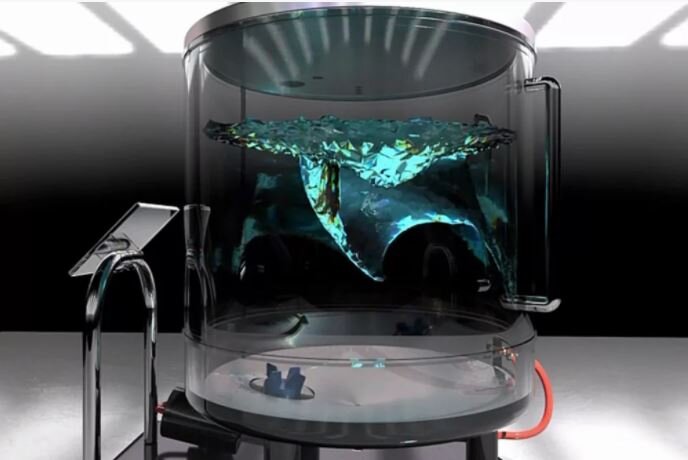

Model the Mixing Process and Blending of Fluid-like Materials

Automated Mixing Guided Process Template

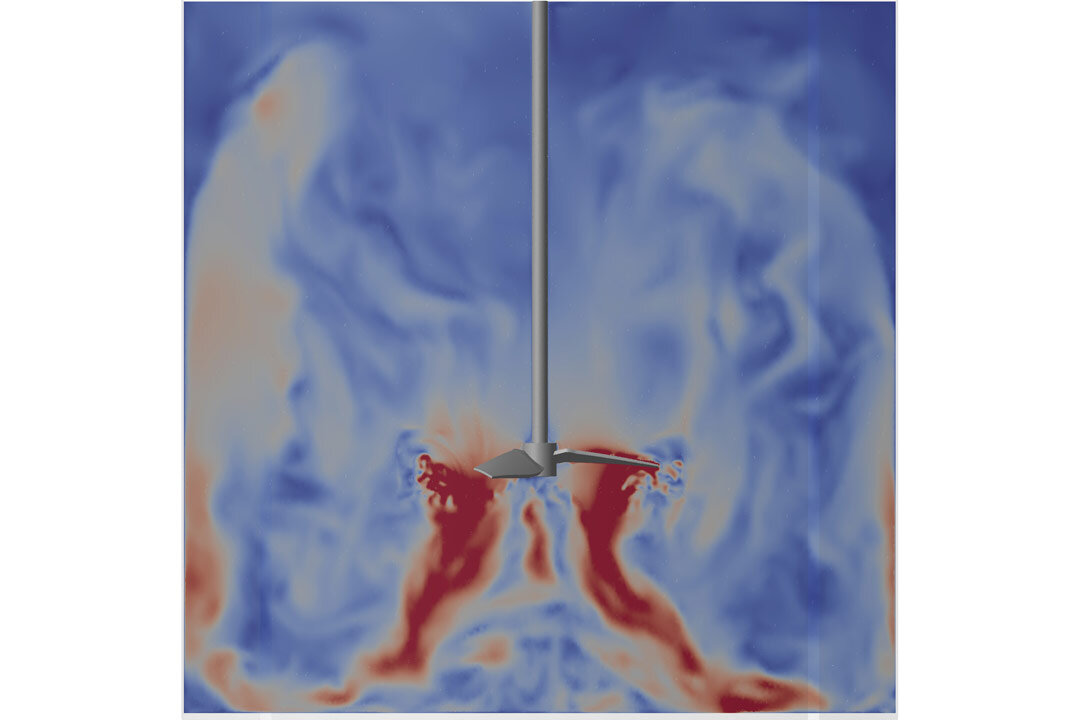

Multiphase, Free Surface and Population Balance models

Scale-Up and Scale-Down

Reduced Order Modeling Capabilities

Ansys Simulation tools accurately predict final mixture compositions. Make adjustments prior to prototyping to meet your quality targets.

Analyze your mixing method to optimize productivity, enabling you to produce more efficiently and save time.

With simulation, you can predict systems performance and assess the mixing process. Validate design work faster with Ansys.

With simulation, you gain better insight to how your vessel reacts to mixing and predict how it handles pressure and thermal loads.

In the past, mixing simulation was a difficult task that was often regarded as an art form, rather than a science. Today, the Ansys portfolio contains CFD software that provides highly accurate mixing simulation. Virtual prototyping gives engineers a huge advantage by allowing them to quickly develop and validate their mixing equipment and processes in a streamlined workspace.

Due to the wide variety of tank geometries and mixing conditions, including rpm, rheology and more, Ansys has developed a streamlined portfolio of compatible simulation software for mixing tanks. The combination of these tools provides in-depth analysis applicable to a wide variety of industries including:

Pharma

Chemical processing

Consumer goods

Food processing

Oil & gas