Pandemic, a Threat or a Possibility?

The waterfall-model, although mostly used in software engineering, works as a great example. Shortly, the waterfall-model is a sequential process were the work phases flow from one to another like a waterfall.

Let’s take and example from product development processes. The waterfall-model, although mostly used in software engineering, works as a great example. Shortly, the waterfall-model is a sequential process were the work phases flow from one to another like a waterfall. The waterfall-model is an idealistic process which is almost impossible to implement into product development of physical products. Waterfall-model is great if the project is highly predictable as you can estimate each phase beforehand.

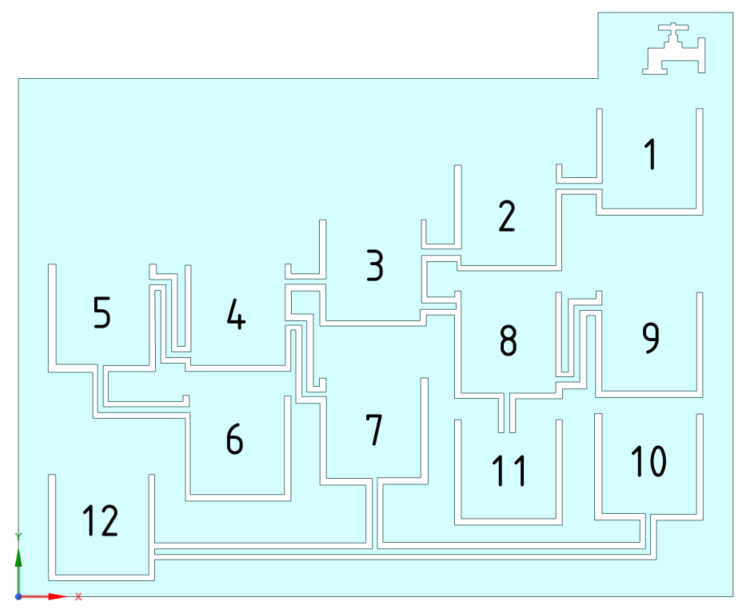

Consider the figure shown below. Which tank fills first? If you get the answer quickly you are most likely wrong and the same applies for your projects. What is the scale? What is the volume flow? What fluid is flowing and what is its viscosity? Which way is gravity? These are questions that should be quite easy to get answers to. What no one predicted was the pandemic that is upon us.

When designing a product there is a need to iterate between development, testing and manufacturing. Every iteration round means physical prototyping which can be expensive in small quantities. Once the prototype is built it needs testing. This can be done inhouse in a testing facility or by a provider. Unless you came up with a perfect product this is the time to start over with the knowledge you gained.

In just few months all the physical prototyping and testing facilities ceased. For the waterfall example this means that there is a huge block in your system, and everything is overflowing. The same applies which ever process you are using. To stop this companies lay off workers thinking it’s the same for everyone. Well let me tell you it isn’t. By digitalizing your prototyping and testing you can overcome these restrictions and keep on working while competitors are sleeping. Adapting digital prototyping and simulation into your product development not only can you keep the iterations running the will run smoother than ever before, all this while reducing costs. Testing is not limited by a probe quantity or testing equipment and can be easily redone if changes are needed. Running parallel tests over the weekend is not a problem, it’s preferred. Companies that have adopted modern digital workflows already had an advantage but now they have turned on their engines.

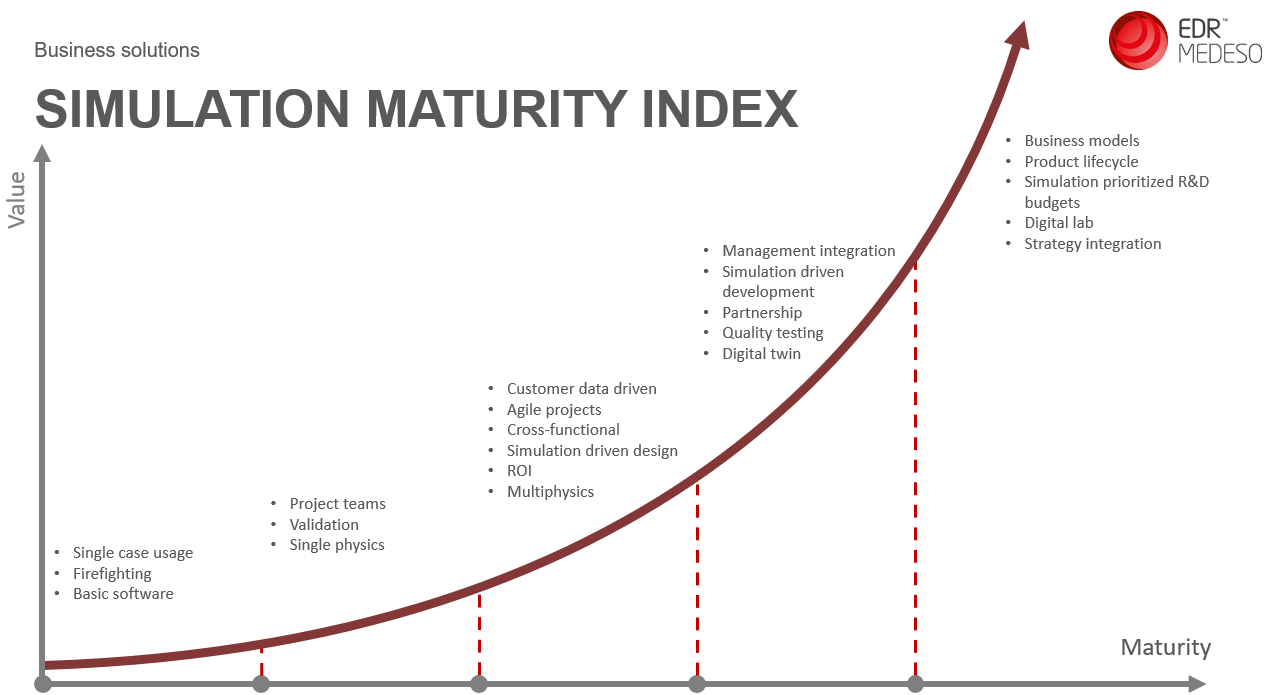

Below chart could help you understand how mature your company is regarding simulation and digital prototyping. Now is the best time to adapt to the future and come out as a winner.

Digitalization and simulation can be adopted with minimal social interaction which is essential these times. Ansys has developed its engineering simulation software for decades to be robust and fast, yet simple to use. Training and support for the software can be done remotely.