Press release – European research project iRel40

Munich – 2 February 2021 – The Europe-wide research initiative Intelligent Reliability 4.0 (iRel40) aims to improve the reliability of electronic systems and microelectronic components. Coordinated by Infineon Technologies AG, 75 science and industry partners from 13 countries are pooling their forces to achieve this goal.

“Enhancing electronics performance through miniaturization and integrating more and more functions is progressing steadily. Performance and complexity are increasing, as the costs per function go down,” says Dr. Reinhard Ploss, CEO of Infineon Technologies AG.

“Powerful electronics form the basis for forward-looking technologies such as electro-mobility, autonomous driving, renewable energies and energy-efficient connected solutions. However, they will only be successful if users can depend on reliable functionality, quality and lifetime. Reliability is a key differentiating factor in international competition.”

iRel40 adopts a holistic approach to optimizing the reliability of microelectronic systems along the entire value chain – from the wafer to the chip and the packaging and finally to the system and hence the actual application. The aim is to significantly reduce failure rates and thus improve product quality and lifetime. This approach also contributes to more sustainable management of our natural resources.

Experts from science and industry in Europe are working together to achieve this. They are relying on the latest insights and methods in material research and failure analysis, including modeling and simulation, as well as artificial intelligence. The project is divided into eight work packages that deal with aspects such as requirements, theoretical principles, materials, test methods, and pilot applications. Infineon will, in particular, contribute its expertise and skills in chip and packaging technology.

EDRMedeso is an Elite Channel Partner of world leading multi-physics simulation tools developer Ansys Inc. The vision is to be your partner – the enabler, in digitalization and simulation driven product development, offering the best in class CAE software, situation adapted solutions, training and expertly performed consulting services.

The company has worked closely with Ansys in product development since 1999, and in building information modeling together with partner Tekla, and the Trimble family under the brand BuildingPoint Scandinavia.

Close to 800 customers, from the smallest consultant companies to 10+ B€ large companies within all industrial segments. EDRMedeso is a Nordic centered company with eight offices across Norway, Sweden, Denmark, Finland, and UK, and about 100 engineers and researchers are at hand for your benefits.

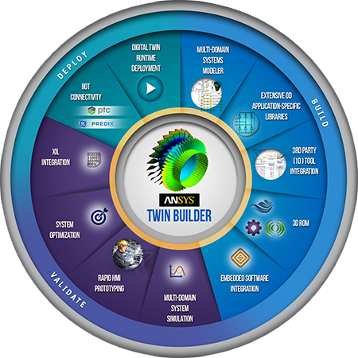

EDRMedeso’s role in the project will focus on digital twin creation based on physics-of-failure numerical models. Connecting engineering simulation models with IoT data to generate accurate prediction models to be used in digital twin for analyzing failure modes and life span of components and systems based on specific operating conditions.

EDRMedeso will support iRel40 partners in digitalization of PoF and DfR models based on highly detailed and accurate numerical models. EDRMedeso’s main capabilities are:

Technical expertise in Ansys software

Simulation prowess, particularly within electronics, FEA and CFD

Proficient in IoT, industry 4.0, digital twins, system modelling

EDRMedeso’s key contributions/objectives:

Objective 2.3: Develop Physics-of-Failure (PoF) models and Design-for Reliability (DfR)

Objective 2.4: Develop Predictive Health Management (PHM) for ECS

Within these objectives EDRMedeso will:

T2.3.2: Develop PoF based on electro-thermo-mechanical analysis, evaluated for both low cyclic- and high cyclic- fatigue. Based on this, create a digital twin for the components/systems in industrial pilot 13 (IP13) together with the partners in WP2 lead by RISE

T2.4.1: Combine PoF with data-driven models (AI and ML) to develop predictive health/maintenance models/management for IP13 together with RISE & QRTECH