Radiall’s struggle with material selection is a thing of the past thanks to Ansys Granta

With no clear formula in the process of material selection, each engineer used their own methods and had an independent material database, with their own file formats (predominantly Excel). The interrogation of material properties and associated information was conducted over email with internal experts and materials suppliers. There was little consistency.

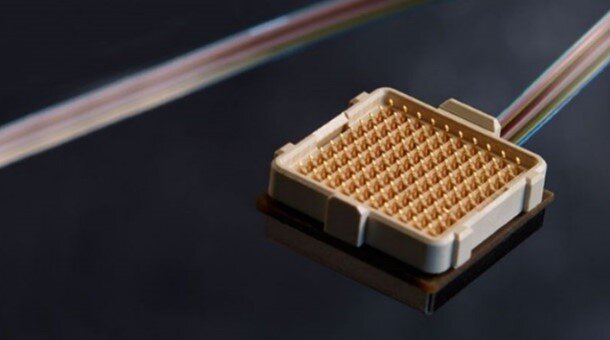

One of Radiall’s core organisation values is to simplify life for its innovators, achieved by streamlining manufacturing, being accessible and easy to work with and delivering leading-edge solutions which, with minimal implementation, drive performance. Given this, it was clear to Radiall that a solution was required to address the challenges encountered by the inefficient selection of materials.

Ansys Granta Selector is used to identify new or alternative materials or for quick materials properties comparisons.

A comprehensive materials database with Granta Selector to assess every viable option – all in one tool.

Integrates directly with Ansys products for easy materials application to simulations plus supports third-party CAD, CAE, FE and PLM applications.

Using Granta Selector halved the time for complex materials studies and properties comparisons.

A comprehensive materials dataset enabled new alloy and polymer identification for product development.

Simulation-ready data from the JAHM dataset for more “relevant and accurate” simulations.

Simplified audit evaluations because Granta Selector data follows international industry standards.

“Using Granta Selector we’re able to undertake rapid properties comparisons: mechanical, thermal, electrical and chemical resistance… not only this but we also have an added benefit of gleaning manufacturing process data.”

Jérémy Sautel, R&T Advanced Materials Team Manager, Radiall

And not only is internal confidence improved. Demanding industry standards for their connectors mean that having a materials selection tool which is recognized by both customers and international standards offers reassurance. “Audit evaluators appreciate Granta Selector” because its data is borne out of industry standards.