Renewable energy sector “wastes not” with Rocky DEM particle simulation

Addressing both climate change concerns and waste management challenges, Enerkem has developed an innovative process to produce biofuels and renewable chemicals from non-recyclable waste. At the core of the technology lies a thermochemical process called gasification, where an organic fraction of the waste is converted into syngas and separated from the inorganic part.

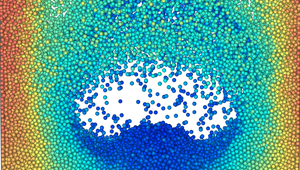

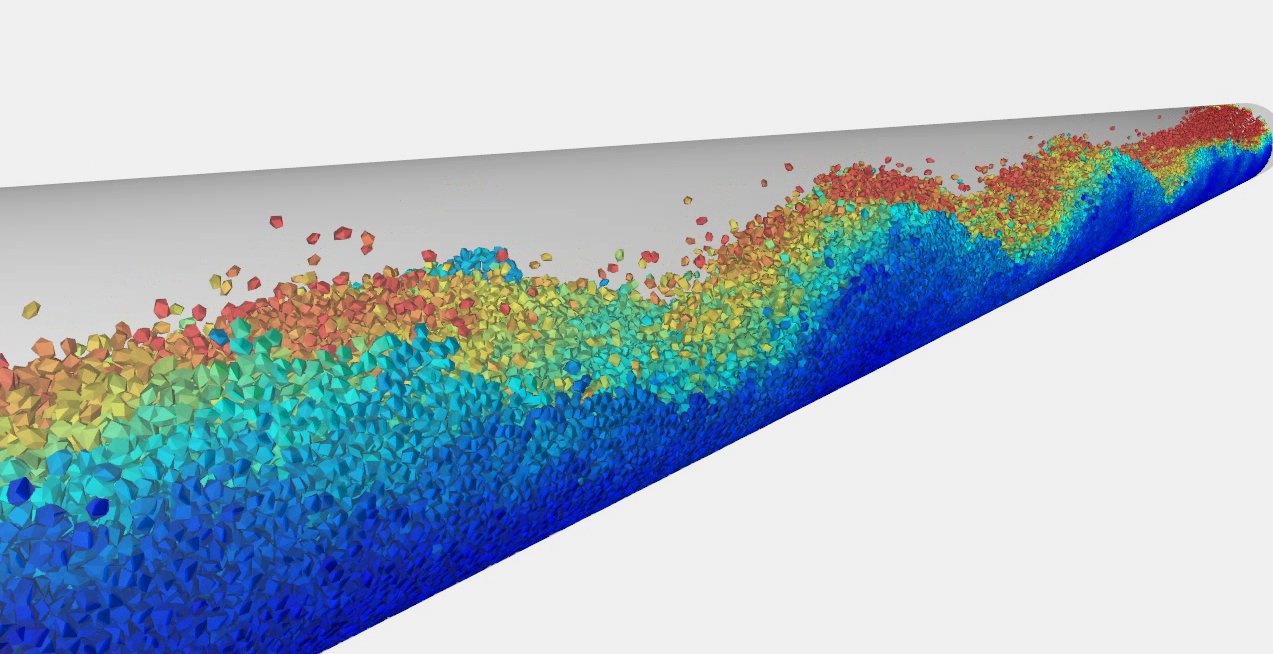

To mitigate the costs and bypass the limitations of empirical calculations, lab-scale experiments, and prototype testing involved in this complex system, the company used a CFD-DEM approach. Ansys Fluent coupled with Rocky DEM’s latest version was the optimal solution to predict the full physics spectrum at the required fidelity level with unmatched simulation speed.

Once Enerkem identified that CFD-DEM was the right solution, the game changer was Rocky-DEM’s solver efficiency running on multi-GPUs. Our simulation problems have tens of millions of coarse-grains, and other DEM software took weeks, months, even a year to resolve. This is not a practical time frame. Rocky DEM enabled us to simulate a large-scale reactor in acceptable time. Months became weeks, weeks became days.

Micaël Boulet, Eng., PhD, Numerical Group Lead

As an emerging industry, converting trash into biofuels has several technical challenges. Analyzing granular and fluid flow in a gasification reactor required physics simplifications and computationally expensive simulations that were not practical within a reasonable time frame. Enerkem had traditionally used scaled-down CFD simulation models and bench testing to explore this domain, but faster and more-representative tools and methods were needed to support fast-paced innovation.

Enerkem added Rocky DEM particle software to its simulation toolkit, applying powerful capabilities to represent the gasification process more accurately, at full industrial scale, and accounting for the right physics spectrum — all in a realistic time frame. New features like solver API allow the company to further tailor the software to the specific application of a fluidized-bed gasifier.

By quickly performing large CFD-DEM simulations with good fidelity, several design options and operating scenarios can be explored virtually, leading to a better understanding of the process and to optimized reactor design. Applied in a troubleshooting context, Rocky helps to diagnose problems and to guide engineers and designers to the right solutions. Beyond gasification, Enerkem has also started to apply Rocky DEM to a wide range of solid handling equipment peripheral to the gasifier reactor, further supporting optimization of the gasification plant.