Simulation is Key to Understanding the Scale of the Problem for EDRMedeso Startup Program Partner ClearWELL Oilfield Solutions.

ClearWELL Oilfield Solutions is leading the way in non-invasive scale control for the international oil and gas industry. The company’s ClearWELL technology is designed to protect onshore and offshore oil and gas wells plus surface production and processing equipment, providing long-term, continuous flow assurance. ClearWELL’s -unique surface unit transmits a pulsed radio frequency (“RF”) signal along internal pipework, which inhibits the deposition and build-up of mineral scale. Prior to installation at the wellsite, the Aberdeen-based company uses simulation tools to predict and visualise the location of scale build-up within the well, and how the RF signal propagates throughout the wellbore. With the help of the EDRMedeso StartUp Program, modelling confidence is high.

Scale build-up in oil and gas wells reduces yield and performance, sometimes to the point of non-production through equipment failure. Downtime to remedy these issues has traditionally been of significant impact, involving well intervention for replacement of equipment, such as downhole pumps, mechanical milling and chemical washes, alongside the lost production value. Ordinarily maintenance to remove the build-up of scale is carried out via injection of chemicals into the well. Even then, if the problem within the well is deep, the injectables may only go so far.

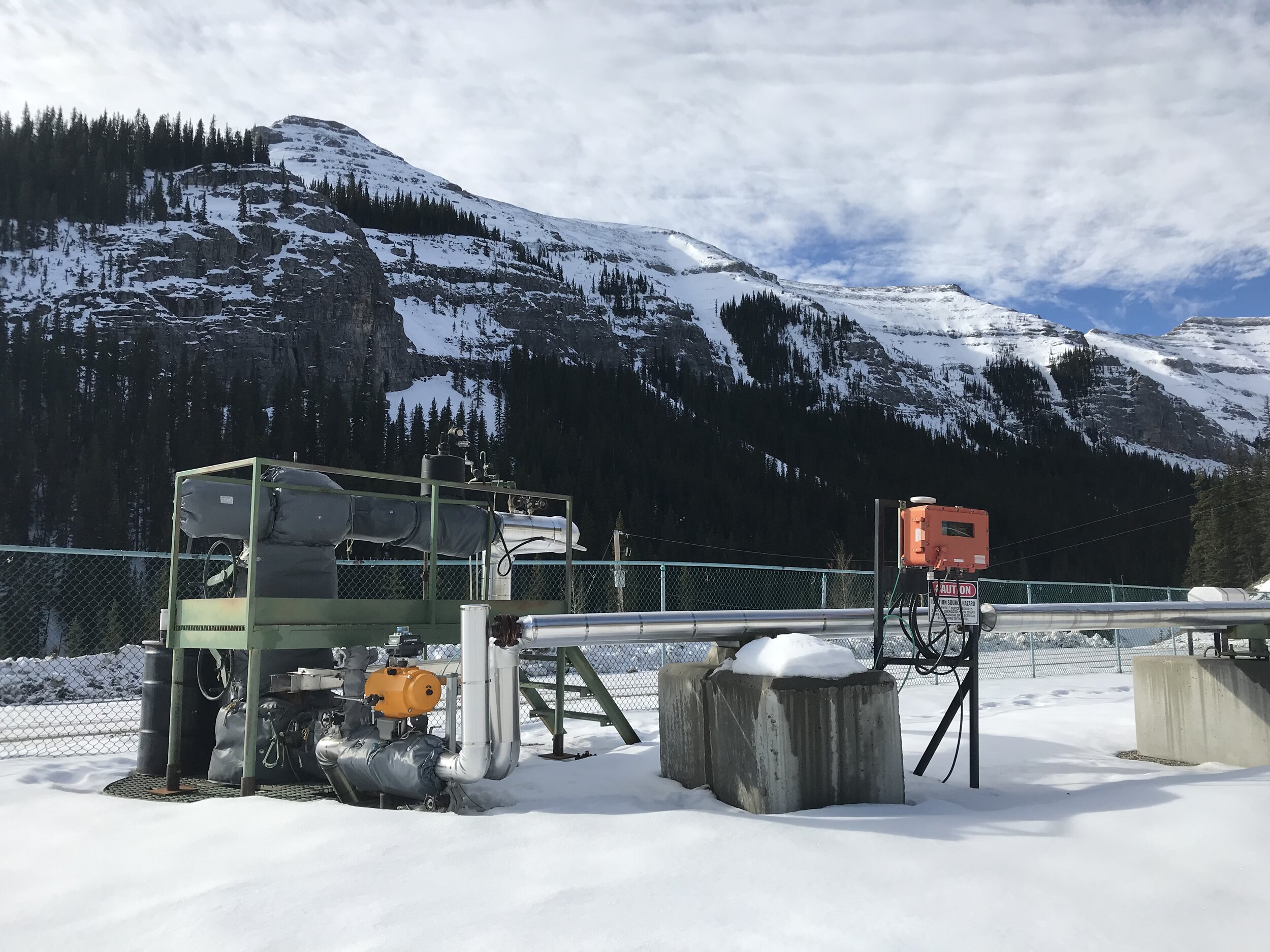

ClearWELL’s solution is a retrofittable, non-intrusive surface device, requiring no well intervention or downtime. Its performance is remotely monitored via satellite communication to ensure continuous protection. A unit deployed at the wellhead transmits a pulsed RF signal downhole, which stops scale from sticking to the surfaces of pipework and equipment that come into contact with the produced fluids. This device ensures that zero downtime is incurred during installation and zero downtime is incurred as a result of scale over the life of the unit’s continuous operation continued production. It is suited to any well with a scaling problem, particularly those under artificial lift, but is also especially useful in scenarios where there are inhibiting factors for traditional intervention and scale remediation methods, such as environment, access and health and safety concerns.

The advantages of using an engineering simulation-based approach prior to site deployment of the technology are clear. Delivering a confident evaluation of individual scenarios, simulation technology provides the insight needed to prevent failure of systems through prediction. Chemical analysis data is inputted alongside structural information and, thanks to simulation, the unique issues presented at each well site can be modelled to provide a case-specific solution, in a timely, highly-validated way.

Not only is simulation used to map scale formation, the HFSS solution within Ansys comprehensive suite of software, models the RF pulse delivered by the ClearWELL™ technology that is required to dissipate this build-up. ClearWELL utilise the HFSS solution to demonstrate to their customers the impact of electromagnetic fields within the oil and gas wells.

ClearWELL CEO, Keith Coutts, identified that simulation would bring advantages to the organisation’s offering, recognising that understanding the fundamentals of RF, and its individual effects at each wellsite, was critical in delivering a robust and fit-for-purpose solution. In startup phase, ClearWELL was able to benefit from the program offered to young, innovative organisations by Ansys via its Elite Channel Partner, EDRMedeso.

With access to the most comprehensive range of simulation tools available, from structural and fluids analysis tools to more specialised HFSS solutions, coupled with a significantly reduced rate in licence fees, the Startup Program was perfect for the company’s needs. However, the discounted cost was only part of the reason for adopting Ansys. The support offered by the EDRMedeso Technical and Support teams played a crucial part in getting the most out of the investment, especially in the early stages of implementation. During a trial period and beyond, working alongside Dr. Rahil Joshi, ClearWELL’s RF Engineer, the EDRMedeso team not only advised on the technical engineering aspects, but also offered help with hardware requirements, processes and training; essentially offering a safe pair of hands. Joshi spoke about the adoption of Ansys:

‘The software has a ‘familiar’ feel, it’s easy to use. I can design quickly and I have the benefit of being able to call upon the EDRMedeso experts if I need to. The combination of solutions means I am always ahead of where I need to be. I can access any number of products that are complementary to the analysis I need to undertake; for example, I can use Ansys Maxwell to study magnetic flux density, SpaceClaim which is very useful to design complex well set up and well surface geometry, as well as the HFSS solution.’

Speaking about Ansys simulation solutions and the ongoing support of EDRMedeso as part of the Startup Program CEO Coutts commented:

‘The accurate and comprehensive nature of the software is enhanced by the quality of the support we continue to receive from EDRMedeso. Initially, our simulations were not particularly advanced but with every version, we get better and better. We are now in the position where we can confidently say that our simulations are impressive; the tool has made a vast difference to our business; the impact on our technical abilities and understanding is significant and we believe that we have a partnership that will continue to allow us to expand our operation, increase our understanding and develop our technology to keep ahead of the challenges that are faced by our customers’.

As for the future? The success of ClearWELL means the partnership continues to flourish, allowing ClearWELL to push the boundaries and deliver further innovation. There is an ongoing dedication to develop the use of simulation as an integral element of the ClearWELL Oilfield Solutions organisation.

Coutts added, ‘A globally recognised leader in the field of simulation solutions, Ansys gives ClearWELL the credibility it requires for its international service offering. Putting combined thought and science behind our scale control solution negates any need for suppositions. Being an Ansys Startup Program member has given us access to valuable technology and allowed us to push on as a company and deliver reassuring, scientific solutions for our customers.’

Carl Rudd, Director at EDRMedeso commented: ‘It’s fantastic to see ClearWELL adopting Ansys simulation solutions to provide insight and confidence in the development of its products and services and, indeed, see the company go from strength-to-strength. Here at EDRMedeso, we are committed to not only delivering the most comprehensive set of tools which allow our customers to get the most out of their investment but to also make sure through our support and access to expert guidance that the value of that toolset only ever increases. Be it an established organisation or relatively new startup, we pride ourselves in forming long term relationships which continue to flourish long after that first converged solution!’

If you’re a startup and believe simulation could be a key factor in your success, take a look at how you too can benefit from the EDRMedeso Startup Program