Simulation Leadership Forum blog with Scania

By Dr. Marcus Oledal, Head of Business Innovation, EDRMedeso

In any case, after a two month break, Simulation Leadership Forum (SLF) returned again on March 24, with another session addressing the challenges that companies face when transforming their product development processes to be simulation driven. A topic that is increasingly important in the age of Covid, when companies are forced to transform faster than they were maybe planning.

I started this particular Forum meeting right after I jumped out of a role as chairman of NAFEMS Conference on Physics-based Digital Twins. The discussions we had just held made it clear that more and more people see the need to look at the whole organization and company strategy if you want to successfully implement an initiative that by definition runs across a whole bunch of silos.

This transformation is (as you maybe know by now ) also the main driver for the Simulation Leadership Forum, a platform for discussing the intangible challenges of simulation driven transformation.

For this session our guest was Mikael Thellner, Technical Manager at Scania Engine Development. We discussed how to reach the full potential of virtual design tools and what that means for business.

Mikael’s idea was that simulation tools should be applied not only to validate, but to drive the development process. In essence going from the reactive process of validating a static design to explore design concepts not constrained by physical properties, processes, cost or lead times.

So how can we achieve this? That was the question that Mikael asked himself when considering how to approach the topic.

Scania already has the experience of using agile, cross-functional and short looped problem solving teams when urgent problems have to be solved, but how do you break away from the sequential and rigid process based on the physical production process for daily development work? Well, listen to Mikaels story in the recording.

As examples from previous SLF sessions have shown, sometimes there needs to be a strong driving force to break up the established physically linked design process. Either a financial pain of prototyping cost or a top-level decision and commitment to establish a new way of thinking.

One of these megatrends that currently has a lot of executive attention is electrification. For many industries this introduces new challenges, but also huge opportunities – if you do things right.

To put this into context, and a main point that Mikael highlighted, this requires more than technology. It requires a new way of organization and project management. It’s no wonder that ‘agile’ has become a buzzword in the world of product development in the last few years. Simulation opens up new possibilities that previously, were unheard of.

Until next time, take care!

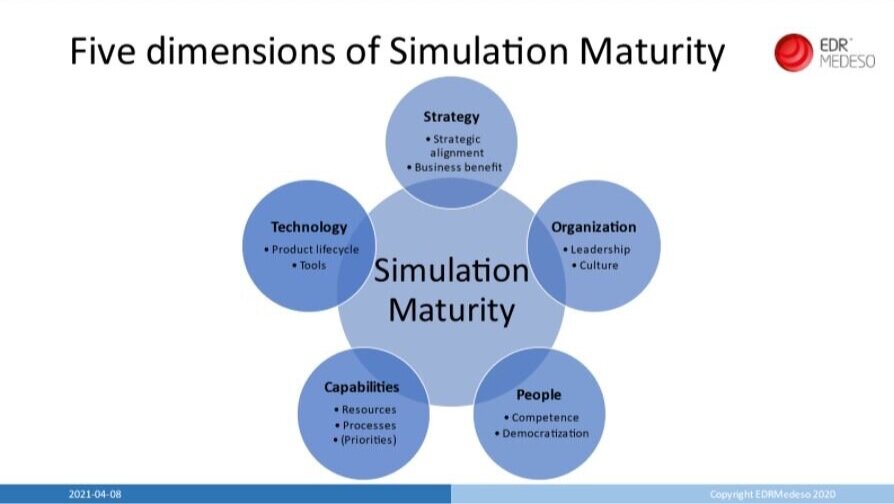

Image: EDRMedeso Simulation Maturity Index