Tackling Challenges in the National Football League with Simulation

The trusted explicit solver did not disappoint. KOLLIDE secured a spot as one of the NFL’s top three awardees for their helmet’s innovative and protective system, which employs 95 pads and an underlying supportive 3D-printed matrix structure. With $550,000 in grant funding to advance their prototype, KOLLIDE is headed into overtime with plans to further upgrade the helmet and scale the manufacturing process.

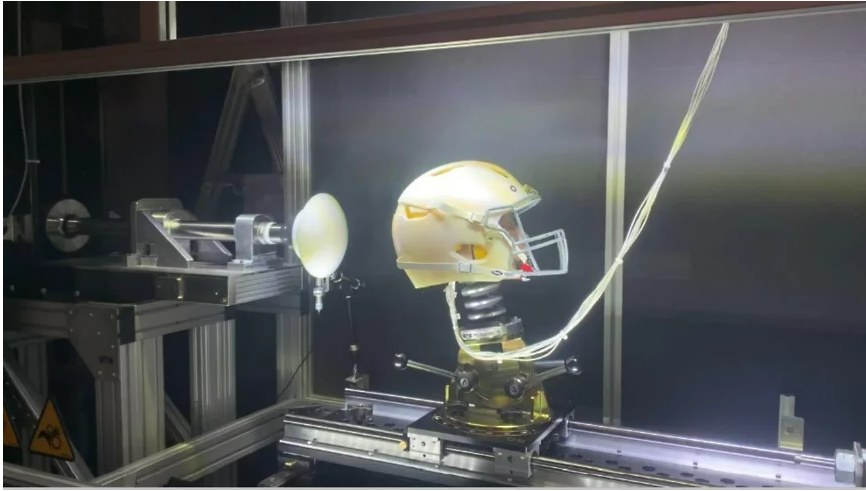

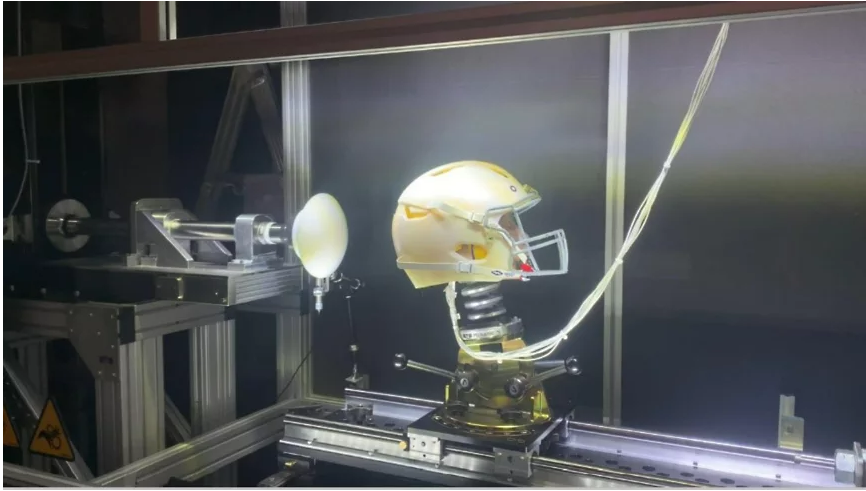

Figure 1. The KOLLIDE football helmet features an innovative system that uses 95 pads to enhance shock absorption and better withstand impact.

Intrigued by the challenge, Kupol, an advanced manufacturing company, gathered fellow local innovators from startups and niche companies to work together toward a solution in collaboration with the École de technologie supérieure (ÉTS), a decades-old engineering school in Montreal.

Together with Kupol, KOLLIDE’s lineup includes industrial design firm Tactix, simulation company Numalogics, and software firm Shapeshift 3D.

KOLLIDE took up the challenge in November 2020, with a one-year-deadline and 12 people who could not meet in person for 10 months due to the pandemic, adding another challenge in itself.

Given the in-person meeting limitations, coupled with budget restrictions for prototyping, the team went digital, turning to virtual design and testing. Implementing simulation as a collaboration tool not only united the team despite member location, but it was critical to saving development time and costs.

Additionally, the NFL provided four open-source finite element (FE) models of helmets with associated impact test methods and equipment.

“The bench test for testing the helmets is an expensive piece of equipment,” says Franck Le Naveaux, a research coordinator for KOLLIDE at Numalogics. “Testing virtually with Ansys LS-DYNA is helpful to improve our speed and reduce costs related to prototyping.”

For nearly 10 years, Numalogics has worked with Ansys and the SimuTech Group, an Ansys Elite Channel Partner. Until now, Numalogics experts relied mainly on implicit modeling to simulate medical devices and their interaction with the human body, however, to simulate helmet impacts, explicit modeling was required. Nine meters per second — the highest impact speed in the NFL’s helmet testing protocol — may be slower than typical simulations that use LS-DYNA, but it’s much faster than what a surgeon does with his hands. Prior to the challenge, Numalogics experts had the most experience using Ansys Workbench for more static, or structural simulations.

But with the speed of impact and composition of the prototype itself, they knew there was only one explicit solver for the job.

“Materials used in the helmet are fairly complex materials” says David Benoit, Biomechanical Simulation R&D Specialist at Numalogics. “Being able to simulate materials that are highly non-linear, viscoelastic and strain rate dependent was a challenge. Ansys LS-DYNA already had all of those profiles.”

A different modeling approach was needed to find the optimal trade-off between model accuracy and solving time to iterate quickly. The team strategized on how to represent the lattice structures best, trying to understand how to model each wall of the structures. Although the predictive results of the simulation by faithfully representing the lattice microstructure of the pads were promising, too much computing resources were required to simulate the whole helmet. As a solution, they homogenized the lattice models to use less computing resources. Still, with 400,000 elements to analyze at the start, KOLLIDE’s simulation journey was certainly not express. Ultimately, each type of simulated impact ran in about three hours on 16 cores. The simulations were performed at three different speeds to demonstrate diverse impacts.

Figure 2. The KOLLIDE Helmet is comprised of 95 shock-absorbent pads.

KOLLIDE approached the helmet as a system comprised of two main parts: the liner and the shell, setting the facemask aside for last. And simulation played a role in each part of the system, allowing the team to test multiple types of liners and shell features, while mitigating risks of late design failure.

“Because the helmet is a system, you cannot optimize a single component without affecting the behavior of the whole helmet” says Benoit. “I don’t see us being able to provide a fully optimized helmet for the challenge without simulation.”

One of the KOLLIDE helmet’s most essential features is its unique liner comprised of networks of lattice-filled, 3D printed structures. These networks absorb a large amount of energy and enable the pads to have flexibility and movement, relative to each other, which boost shock absorption depending on the direction of impact. Additionally, the group experimented with different printing techniques and materials to consider how lattice structures behave and sustain multiple types of impact at different temperatures.

Figure 3. Ansys LS-DYNA and 3D printing reduced physical prototyping costs and accelerated product development.

The final pads were printed using fused deposition modeling (FDM). For the shell, KOLLIDE tested different compounds to find the best material for sustaining impact before opting for a soft shell to better distribute impact onto the underlining inner padding. The rigidity of the pads and shell were calibrated using Ansys LS-OPT, a design optimization tool built into LS-DYNA, allowing to develop a fully automatized optimization workflow. In another success, the finished pads are able to shear and mitigate rotational acceleration which has been found to be the most potentially damaging type of acceleration for the brain.

As a last step, the team created the facemask, which was less of a redesign and more of a fit adjustment to the new liner and shell.

KOLLIDE’s final product looks like a regular helmet but holds advanced features that highlight its lattice structure, such as its customizable fit. There are 95 shock-absorbent pads mounted on a sling in suspension with the shell — an area where simulation helped to improve energy distribution.

“This project would not at all have been possible without using simulation, given the fast timeframe. We would have submitted a helmet, but not a good one,” says Franck Le Naveaux, a research coordinator for KOLLIDE at Numalogics. “Also, with designers working with computer-aided design (CAD) software, bringing concepts to us and testing them, simulation was critical to an efficient workflow.”

Though no team met the NFL’s goal, KOLLIDE scored just above the desired rank. The helmet’s promise was so impressive that the team was selected with two other finalists to receive funding to advance their prototypes.

KOLLIDE is gearing up to do just that, focused on exploring new concepts and scaling 3D printing to produce an upgraded helmet at a faster pace to meet the HPS goal. In accordance with the grant, the NFL will follow KOLLIDE’s progress for a year. The teams have six months to submit a new prototype, then another six months to produce an advanced final product.