The future of product development is digital

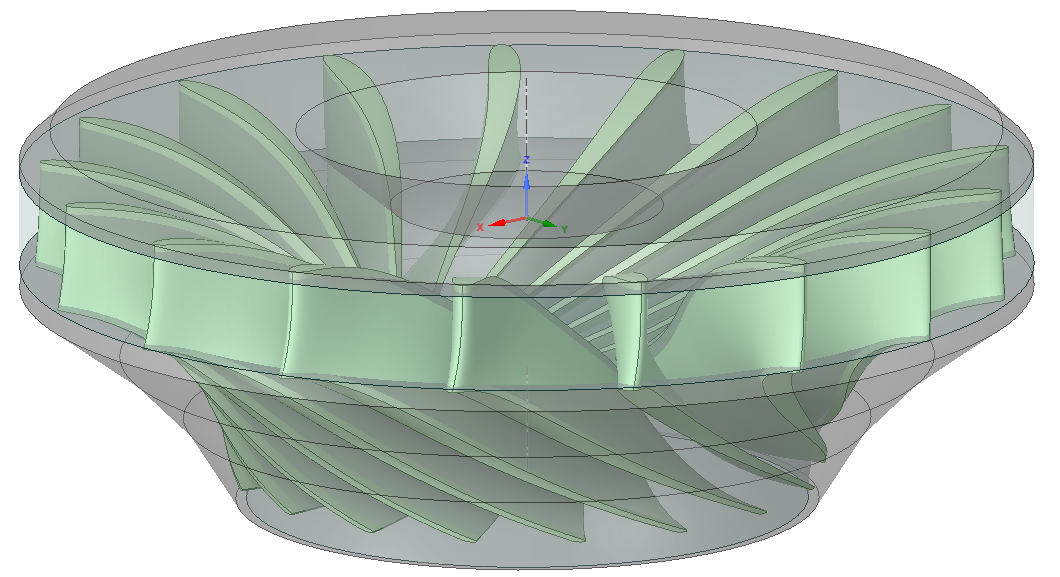

In the following webinar we show an advanced application of the Digital Lab. Here we present a framework for variable-speed Francis turbine design. To minimize the risk of runner fatigue, the turbine is optimized from both a hydraulic point of view, as well as maintaining the structural integrity. This is done by coupling fluid and structural simulations, and optimizing design based on efficiencies, stress values and more.

The presented process is fully automated, with no need for human interaction. A MATLAB design code and different ANSYS simulation tools are coupled using the optimization software ANSYS optiSLang.

Watch all the other webinars here