Turn Costs into ROI with EMC Simulation

We spent nearly a million euros last year trying to fix what simulation could have prevented. – Design Director, Consumer Electronics

For many electronics manufacturers, EMC compliance is seen as an unavoidable expense. But by replacing multiple rounds of physical testing with simulation, companies are turning a regulatory requirement into a powerful profit driver. In this article, we’ll show you how EMC simulation pays for itself in under a year and keeps delivering returns with every product cycle.

Electromagnetic compatibility (EMC) is a critical requirement for any electronic device entering the market. This means that every electronic product must be able to operate as intended within its electromagnetic environment, without causing or suffering from unacceptable interference. In Europe, EMC compliance is mandatory under the EMC Directive (2014/30/EU). Failing to meet these legal requirements can lead to delayed launches, costly redesigns, fines, or even withdrawal of products from the market.

Controlling electromagnetic interference (EMI) is central to EMC compliance. EMI occurs when unwanted signals disrupt a device’s performance. Often invisible until the damage is done, EMI can be particularly dangerous in settings where accuracy is vital, such as medical devices, aerospace systems, or industrial automation. Traditionally, compliance required multiple costly lab test cycles, but today, digital simulation lets engineers detect and fix EMI issues earlier, reducing prototypes, costs, and delays.

Table 1. Estimated yearly EMC testing costs, physical prototyping and internal costs.

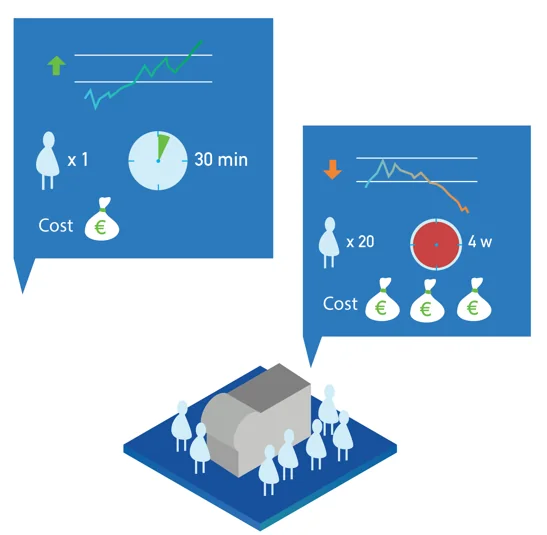

A high-level cost assessment shows the potential savings of EMC simulation. Although these are estimates, the numbers in the table are drawn directly from real industry patterns.

On average, the external costs of a single prototype cycle include PCB fabrication, component sourcing, shipping, test lab fees, and possibly EMC or other consulting. Each cycle also requires internal work hours for documenting, reporting, designing, redesigning, testing, and sourcing components. The total cost in money and time depends on the project’s complexity and scope.

Reducing physical lab testing also cuts ongoing internal expenses for equipment, facilities, and maintenance, including investments, depreciation, calibrations, rent, storage, utilities, cleaning, and consumables such as connectors, cabling, and soldering materials.

Let’s define a conservative ROI scenario using the table values:

Table 2. Estimated yearly EMC testing costs, project delay costs.

Delays do more than push back a launch date: they trigger costly adjustments and reduce competitiveness. Direct costs include extra marketing, changes in sourcing and logistics, contractual penalties, and other timeline-related expenses.

Indirect costs arise when specialist hours, testing facilities, and resources are diverted to fix the delayed project, slowing dependent projects and disrupting schedules. This ripple effect can stall innovation, as engineering focus shifts from developing new ideas to fixing existing problems.

As shown in Table 2, these savings can reach hundreds of thousands of euros annually.

* Enter your company’s own estimates based on your chosen calculation methods.

Table 3. Estimated yearly EMC testing costs, possible hidden and long-term costs.

Looking at Table 3, the possible hidden and long-term costs may include the average cost of product recalls, market withdrawals, warranty replacements, or legal disputes. The largest financial impact comes not from these direct costs, but from lost revenue: for example, when a product must be sold at a lower price or delivers weaker performance compared to competitors due to design compromises.

A single compliance failure or defect can also damage brand reputation, eroding customer trust, investor confidence, and employee pride. In some cases, this damage is permanent.

When adding simulation to the design process, you factor in benefits such as faster time-to-market, better allocation of engineering resources, improved cost-to-performance without rushed EMC fixes, and reduced liability risk. This makes the business case even stronger, with savings that are not only significant but transformative.

** These values should be calculated using selected internal risk assessment methods, for example, multiplying risk probability by risk severity.

Table 4. Estimated yearly EMC testing costs, total cost and saving per year.

According to this high-level assessment, using simulation can save up to 420 500 € per year and 45 days of time for your team. Compare that with the cost of implementing EMC simulation tools and training (50 000-70 000 € upfront). The payback is less than one year, and every iteration saved thereafter is pure profit.

The results make a strong case for using simulation not just as a troubleshooting tool, but as a core element of the product development strategy.

Here’s how your next 30 days can look:

Request a free demo for your PCB

In physical testing, near-field probes are a great tool for tracking EMI issues on a PCB. However, simulation can not only do exactly the same, but take it even further: plot near fields, visualize problem areas, and pinpoint exactly which parts of your design cause peaks in your radiated EMC report, at any frequency.

When embedded into the design phase, simulation changes the game from reactive firefighting to proactive design.

EMC simulation is not just an engineering upgrade – it’s a win for the entire business:

Request a free demo for your PCB

Webinar on Demand: Solving EMI/EMC Challenges in Electronics Design