Unleashing the Power of Electrification through Simulation: Insights and Innovation

Electrification is, at its core, the journey toward increasingly advanced electrical systems. From electric vehicles and charging stations to electrified transportation in marine and aerospace, the applications are vast and growing. These shifts are driven not only by environmental concerns but by the remarkable efficiency and flexibility that electric systems bring. For instance, electric motors can achieve efficiencies up to 98%, far surpassing combustion engines. But beyond efficiency, electrification reduces reliance on complex mechanical components, enhancing system reliability.

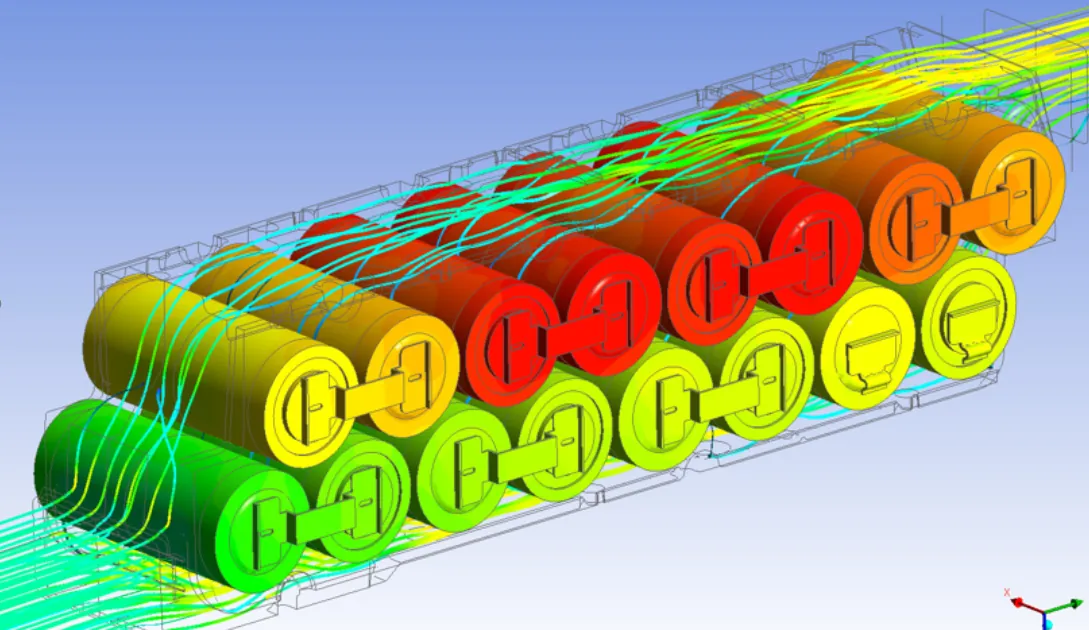

One of the enduring challenges of electrification lies in energy storage, with batteries as a critical focal point. Creating an efficient, safe, and long-lasting battery requires innovative solutions, especially for industries reliant on high energy capacities, like automotive and aerospace.

Simulation technology is central to addressing the challenges of electrification, enabling engineers to design and optimize components and systems more efficiently. The key to successful electrification is not only improving individual components – such as electric motors, transformers, and power electronics – but understanding how they interact within a larger system. This is where advanced simulation tools like those from Ansys come into play, empowering engineers to create high-fidelity models and conduct multiphysics simulations.

By utilizing simulation-driven design, companies can optimize systems from the ground up, reducing reliance on physical prototyping and accelerating time-to-market. Simulation enables them to test, iterate, and refine complex interactions between components, ultimately ensuring the optimal performance of the entire system.

Looking forward, system-level simulations will become essential as industries strive for increasingly sophisticated electrified systems. Simulation not only drives product development but also enables the creation of digital twins. These virtual models provide real-time insights into system health and enable predictive maintenance, reducing downtime and enhancing asset management.

In essence, electrification is about more than just going electric; it’s about creating cohesive systems that interact seamlessly. By harnessing the power of simulation-driven design, industries are positioned to innovate in ways that reduce environmental impact while optimizing performance, setting a new standard for the future.

Electrification, powered by simulation, is paving the way for a cleaner, more efficient tomorrow. Whether you’re an engineer, a product designer, or an industry leader, the future is electric, and simulation is the key to unlocking its full potential.

Watch our webinar on demand: Simulation of Components and Systems for an Electric Future