CEA Aims to Democratize Space by 3D Printing Rocket Engines

While a handful of mega-wealthy individuals — including Richard Branson, Elon Musk, and Jeff Bezos ― have received plenty of media attention for their efforts to establish space tourism, the potential of space for a range of business applications is enormous. From launching satellites to transporting goods, the worldwide space industry represents untapped opportunities for product and service commercialization. It may well be the “final frontier” for a new generation of ambitious entrepreneurs.

One such entrepreneur, (and a self-confessed space evangelist) is Ewan Craig, who founded Connect Everything Aerospace (CEA) in the UK in 2020, based on a novel idea he developed during the early months of the COVID-19 lockdown. While many of us were taking long walks, assembling puzzles, or baking bread, Craig was imagining an unexpected way to make space more accessible, more affordable, and more democratic by 3D-printing rocket engines. Less than 18 months later, with support from the Ansys Startup Program, Craig is preparing for his first test launch. Recently I talked with Craig about his unique vision — and how he’s managed to realize it so quickly.

Ansys Advantage: When I hear the words “additive manufacturing,” rocket engines don’t seem like a natural fit. After all, we use “rocket science” to express the most extreme example of product complexity. So how exactly did the concept for CEA originate?

Ewan Craig: I’ve always thought aerospace engineering is just the coolest thing we do as human beings. The moon landing, sending rovers to other planets, having men and women living in orbit around our planet ― it’s so incredible. So during the initial COVID-19. lockdown, I did an online open course, an introduction to basic rocket science, created by the Massachusetts Institute of Technology (MIT). I just loved it. I started doing some research, and I learned about an aerospike engine design that was conceived in the 1960s but never really got off the ground, pun intended. And there was a moment when I thought, “Hold on a second. Should I try and redesign this for today?”

The engine has an unique design that allows it to deliver maximum thrust as it climbs through the atmosphere, self-adapting to the changes in ambient pressure to support optimum exhaust expansion. But that unique design makes it heavy, hard to manufacture, and expensive to produce using conventional materials and fabrication processes. Additive manufacturing, or 3D printing, is really the only way to produce it at scale. With 3D printing, complexity is not really an issue. As long as you optimize the design, it’s just a matter of pressing a button. By combining the really modern technology of 3D printing with this rather old invention of the aerospike rocket engine, you can actually make something that’s viable today, both financially and practically. And that was the genesis of CEA.

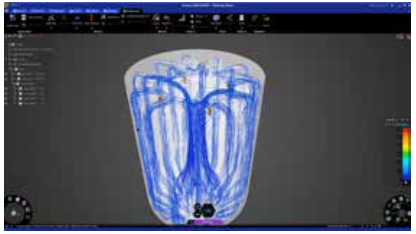

CEA relied on Ansys Discovery (pictured) and Ansys Fluent in creating and verifying the design.

Ansys Advantage: Once you have the ability to massproduce rocket engines, quickly and affordably, what does that make possible?

Craig: The opportunities for a printable rocket engine are huge. I like to think of it as similar to the Ford Model T moment in cars. If you’re able to start making these things at a fraction of the price and with far less labor ― and skilled labor, especially — then it means you don’t need a massive, government-funded operation like NASA to put things into space. It can become a cheaper, more accessible enterprise. You can have much smaller rockets powered by cheaply built rocket engines. You can have small companies offer services like satellite launches. You could have loads of little startups popping up in the UK or in America or all over the world, especially in developing nations where space exploration is something that’s just not happened. Right now it’s a game for the richest men on the planet, and that should change. A company like CEA actually can start instigating that change.

Ansys Advantage: What are the business challenges you’ve faced as a young entrepreneur with a big, ambitious idea?

Craig: From the get-go, this was never really a business enterprise for me. I was doing this work out of a scientific curiosity. I was just trying to solve the technical problems. But, in doing that, I was challenged because I didn’t have access to the best tools for my design exploration and simulation needs, specifically Ansys Discovery and Ansys Fluent. Being able to access Ansys software through the Startup Program was incredibly important. If you imagine the internal structure of this rocket engine, it’s a labyrinth of channels, passages, coolant flows, and all manner of different areas and surfaces. You can’t make a million prototypes and destroy them. You have to be absolutely confident in your designs before you start printing them, and Ansys delivers that confidence quickly. I couldn’t have proven my concept, founded a company, applied for patents, and identified a 3D printing partner without the credibility Ansys provided me. I’ve been hugely supported by Ansys throughout the engineering phase, and now it’s time to start thinking about commercial viability and making a profit ― whether that means manufacturing rocket engines in-house or licensing the technology to others. I like to describe CEA as being in the pre-revenue phase, but it’s brilliant to imagine where this company could go. And I wouldn’t be at this stage without Ansys.

CEA has designed an innovative rocket engine in one part, 3D-printed to contain an injection manifold, regenerative cooling channels, a combustion chamber, and an entirely unique aerospike nozzle. CEA relied on Ansys Discovery and Ansys Fluent in creating and verifying the design.

Ansys Advantage: Where are you in the development cycle — and what’s next for CEA?

Craig: On October 11, we officially produced the world’s first single-piece rocket engine, 3D-printed by our partner Velo3D. In the world of rocket engines, once you’ve built the first one, you do what’s called a static test fire. So you strap the thing to the ground and you fire it. You pump your oxidizer and your fuel through it, and you see how well it keeps itself cool, as combustion releases an incredible amount of energy and heat. We’re planning a test flight soon and, if it works, that will be the first time one of these engine designs from the 1960s actually ever got off the ground. I’m excited and I’m also confident. My Ansys simulations say it’s going to work, and so I expect it to work.

Ansys Elite Channel Partner in this project EDRMedeso, UK

Article from Ansys Advantage 2022/2