Making Waves in Sustainable Energy

Picture: By helping to ensure that every component of the O2 design can withstand the harsh marine conditions, Ansys Mechanical has been critical in successfully launching this game-changing green energy solution.

While solar and wind powered technology have begun to replace fossil fuels ― and both represent fundamental alternatives in the global effort to combat climate change — they will not be enough to meet these ambitious goals: the world needs to embrace and exploit an enormous, yet overlooked, power source, the tides. By harnessing the power of natural oceanic flows, countries around the world can benefit from a clean, renewable, reliable and predictable energy source with a relatively small physical footprint and minimal environmental impacts.

Tidal stream power generation is still an emerging renewable technology, primarily because it involves complex engineering challenges. These problems need to be addressed successfully before tidal power can be captured on the massive scale needed to support aggressive renewable energy targets.

Orbital was founded in Orkney, Scotland in 2002 with a straightforward goal: to bring together the engineering expertise to develop the advanced technologies needed to commercialize and install powerful, game-changing tidal turbines around the world.

Orbital’s flagship solution, the O2, is a 74 meter-long turbine that is moored to the seabed by an anchoring system. When the O2 is positioned in a powerful tidal stream, large 1MW twin underwater rotors capture this energy. The rotors’ 10-meter blades provide more than 600 square meters of area to capture flowing tidal energy. Electricity is transferred from the turbine to the seabed via a dynamic cable, while a static cable running along the seabed carries the energy to an onshore distribution facility.

Picture: Orbital Marine Power recently completed the first installation of O2, its innovative tidal turbine-based energy generation system, off the coast of Scotland.

The O2 was designed by Orbital to address many of the historic obstacles to commercializing tidal turbines. Unlike seabed-mounted underwater turbines, its rotors are attached to legs that can be lifted to the water surface for maintenance and repair. This is a critical design feature, as oceanic conditions are harsh ― and the difficulty and high costs of equipment maintenance have historically been viewed as significant obstacles to the broad commercialization of tidal turbines.

With its thoughtful design, the O2 is expected to have significantly lower production and maintenance costs than existing tidal turbine designs. Orbital hopes that the O2 will prove to be a key enabler in the widespread adoption of tidal-based energy generation.

Since Orbital was founded nearly 20 years ago, its engineering team has adopted advanced solutions, including Ansys Mechanical, along with offshore test and demonstration programs to support the development of its tidal technology.

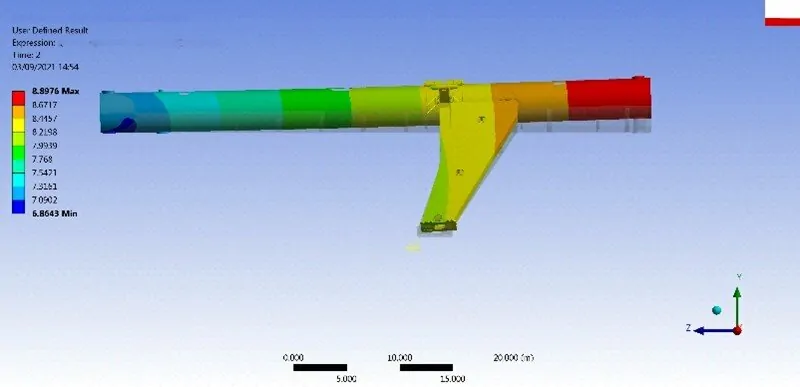

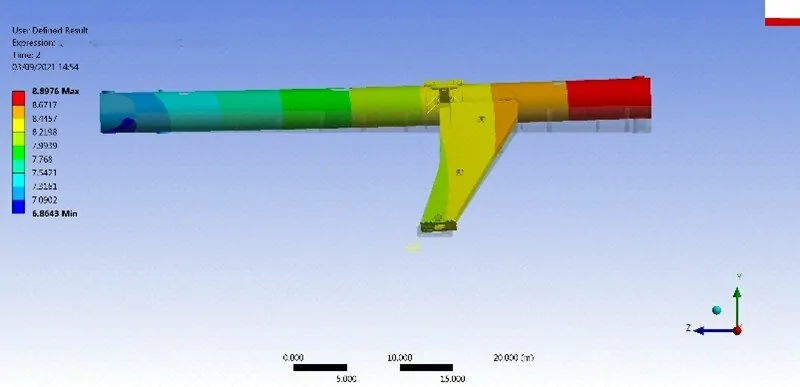

Image of an output plot of some of the O2 structure from Ansys

Supported locally by the UK’s Ansys Elite Channel Partner EDRMedeso, engineers at Orbital have used Ansys Mechanical to simulate the structural and environmental loadings on the entire turbine design, from the rotors to the anchors and chains, to ensure that it will successfully withstand harsh oceanic conditions, including extreme weather events.

Ansys Mechanical has enabled the Orbital development team to study fatigue, vibration, stiffness, bending and other issues both at the system level and the component level — including a rigorous analysis of the hundreds of individual connection points across the O2 design. Ansys Mechanical integrates seamlessly with other engineering tools used by Orbital’s engineers, making it easy to collaborate and hand off design tasks.

By applying Ansys Mechanical to quickly model and verify its designs in a low-cost, risk-free virtual environment ahead of offshore testing, Orbital has been able to accelerate the initial design of the O2, cutting years from the development cycle.

Orbital engineers continue to leverage Ansys Mechanical to explore performance and cost improvements such as mass and weight reduction, improved manufacturability, and the use of alternative materials. Many members of the engineering team began using Mechanical while at university engineering programs, and it remains the industry standard today for fast, cost-effective, accurate structural analysis.

Recently, Orbital completed installation of the O2 near its headquarters in Orkney, Scotland, which has some of the strongest tidal currents in the world.

Anchored in the Fall of Warness at the European Marine Energy Centre (EMEC), where tidal speeds can exceed three meters per second, the O2 is connected to the onshore electricity grid. The O2 can produce enough power for 2,000 homes, offsetting approximately 2,000 tons of CO2 production annually that would otherwise be emitted from fossil fuel generation. To augment its positive environmental impact, the O2 project will shortly also provide power to EMEC’s onshore electrolyzer, which generates green hydrogen to demonstrate how tidal energy can additionally supply predictable renewable energy to transport and heating sectors.

Building on the success of the O2, Orbital is now focused on broad commercialization of its technology by supplying multiple turbines to create tidal energy farms in regions of the world with strong tidal currents. As more and more O2 turbines are deployed, commercialization costs are projected to fall steeply from the product’s rollout of the technology in Orkney, making tidal power an important component of the US, UK and worldwide efforts to eliminate carbon emissions as fast as possible.

Looking ahead, Orbital will continue to leverage Ansys Mechanical – drawing on the technical support expertise offered by EDRMedeso – alongside other advanced engineering tools to continuously improve its product designs for both cost and performance. While tidal energy generation still lags behind wind and solar power, the ability to design, test and verify the performance of Orbital’s tidal turbines in a virtual environment is essential in closing that gap ― and fully realizing the potential of oceanic energy to turn the tide on climate change.