The Role of Ansys Granta Selector in Syncrolift’s Durable Shiplift Innovations

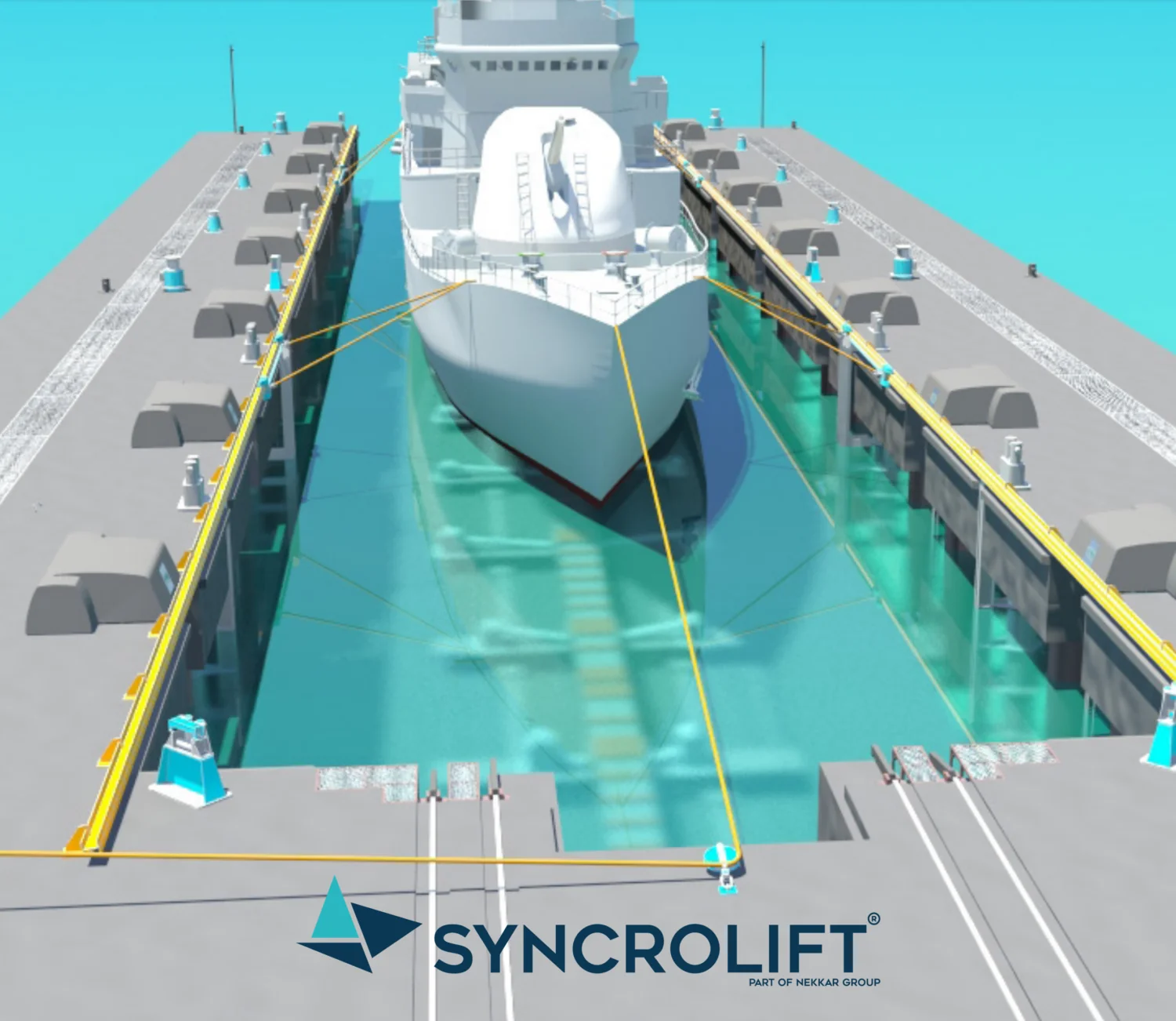

The shipyard and marine equipment industry demands products that can withstand extreme environmental conditions and heavy operational loads. For Syncrolift, ensuring the durability, safety and efficiency of their systems is therefore crucial. Achieving this requires a thorough material selection process to identify materials capable of meeting these strict demands. At the same time, balancing cost-effectiveness and sustainability adds another layer of complexity to the decision-making process. Syncrolift turned to EDRMedeso for a solution, with the hope of overcoming these challenges.

The decision landed at the tool Ansys Granta Selector, since it offers an advanced, data-driven solution that simplifies and enhances the material selection process. The software combines a vast database of reliable materials information with powerful selection and comparison tools, empowering the engineers to make informed decisions based on critical criteria such as mechanical strength, corrosion resistance and fatigue life. By providing streamlined access to hard-to-obtain material data, the Ansys software became an essential resource for optimizing Syncrolift’s designs. It enabled their team to refine products for long-term durability and performance, even in the most demanding environments, ensuring that their systems continue to meet high standards of safety and efficiency.

By integrating the software into their workflow, Syncrolift thus achieved several key benefits that have transformed their material selection process:

Together, these benefits have transformed Syncrolift’s engineering processes, ensuring their products consistently meet the highest standards of quality and reliability. These results demonstrate how Ansys Granta Selector has become a valuable tool in ensuring Syncrolift’s products meet the highest standards.