Five Innovative Startups That Have Used Simulation to Cut Costs

Often written off as an asset only reachable by mature companies, in reality, early adoption of simulation can significantly help startups save money, with specialized packages such as the Ansys Startup Program unlocking the full benefits of market leading simulation software for new companies, enabling them to boost the development of cutting-edge technology, minimize expensive physical prototype tests, cut time to market, and reduce expensive re-designs.

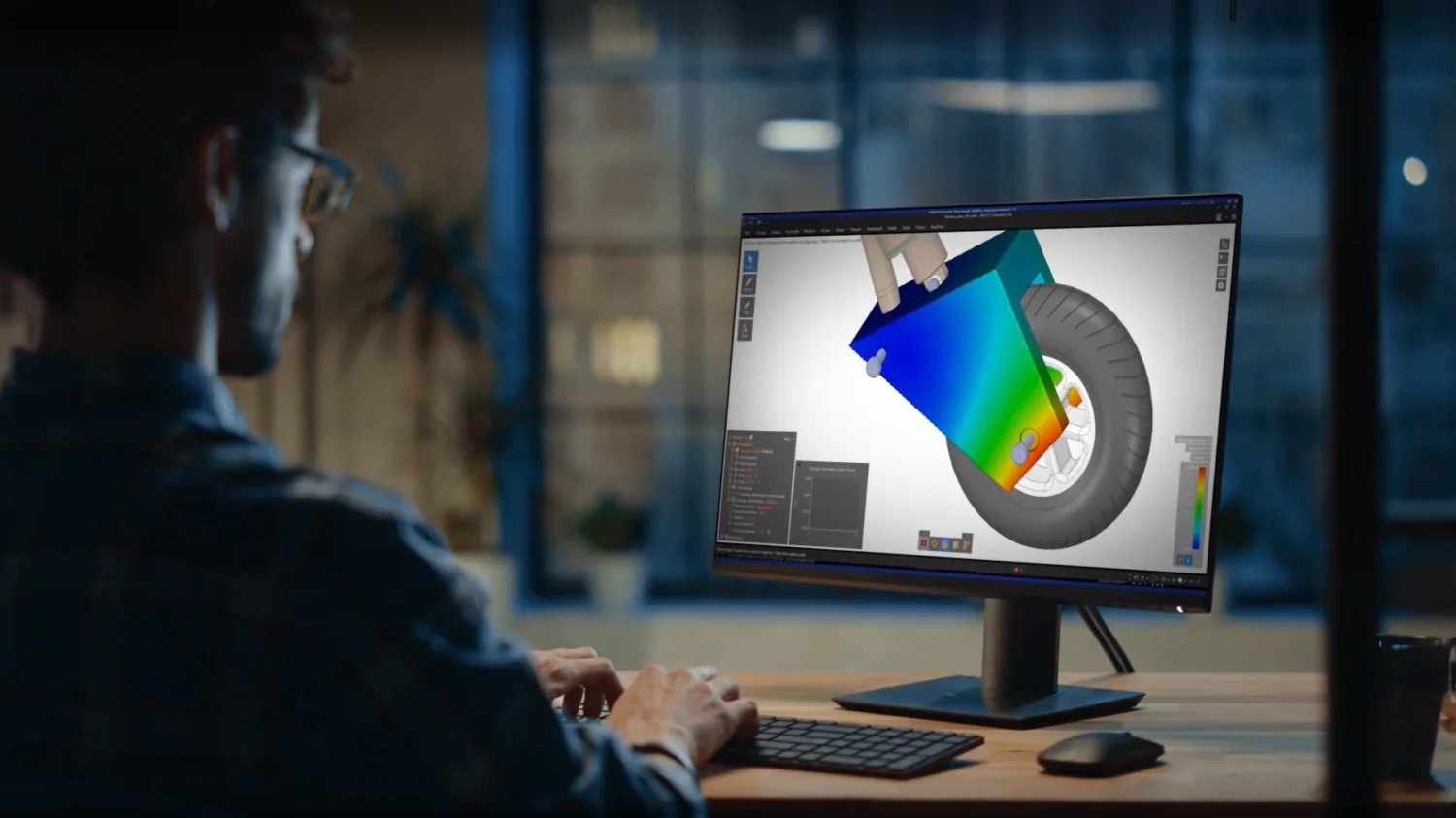

Simulation software enables the creation and/or adaptation of digital models that undergo real-world processes within a virtual environment. These accurately mimic behaviors and interactions that enables detailed analysis, testing, and optimization of designs. This helps drive down costs, reduce complexity, eliminate risk, and brings new products to MVP sooner.

Simulation helps engineers and designers perfect new products and technologies while saving startups money. Traditional prototyping methods can be time-consuming and expensive, involving multiple iterations and physical prototypes. In comparison, simulation software allows for virtual prototyping, where designers can test different designs and materials within the digital environment, and make changes on the fly, as many times as needed. This not only speeds up the development process but also reduces the need for physical experiments, saving on material and labour costs.

For example, a startup developing a new electronic device can use simulation software to test various circuit designs and thermal management solutions. By identifying and fixing issues in the virtual world, the startup can avoid costly redesigns and delays in the physical prototyping phase.

Norwegian startup Optifloat joined the Ansys Startup Program in 2021 and, with expert mentoring from the EDRMedeso team, embraced simulation in their design process of floating offshore wind turbines. Virtual testing of their products was critical for controlling costs, as physical testing in pool tank and instrumenting the test model with sensors is very expensive, it’s natural to do virtual testing and prototyping before going into the pool tank.

The Ansys Startup Bundle has been instrumental in reducing costs and streamlining the innovation process, providing advanced simulation capabilities that allow OptiFloat to model complex behaviours accurately.

Find out more about Optifloat >>

Cardiff based Space Forge joined the Ansys Startup Program with EDRMedeso in 2021, leveraging Ansys to facilitate two-way trips to space as safely and as efficiently as possible. The predictive accuracy of simulation software was critical for developing a vehicle that could successfully drops from an altitude of approximately 400km at a speed of more than 19,000 miles per hour – to sea level at around 20 miles an hour.

Find out more about Space Forge >>

The ability to rapidly assess a large number of design load cases in a short time frame is crucial for Myriad, a startup based in Stirling, Scotland. Joining the Ansys startup program in 202X, Myriad made use of Ansys Mechanical and Ansys Fluids to optimize turbine design details and facilitate seamless communication with engineering consultancies, stakeholders, and investors. This swift iteration and adaptation has been vital to development and ensured that the project has progressed on time with no costly delays.

Norwegian Startup Otechos required simulation to help study the behaviour of fluids and structural aspects of their pumps and compressors. Making full use of the structures and fluids bundle of Ansys applications, The team undertook fluid simulations (CFD) and Finite Element Analysis (FEA) to ascertain knowledge about the machinery and process that would give their prototypes a head start. This saved many steps in development that would have otherwise have piled on the costs.

Find out more about Otechos >>

STILFOLD joined the Ansys Startup Program in 2024 having identified the need to bring repetition, precision, and scalability to its curve-folding technology for sheet metal. Using Ansys LS-DYNA, the team have been able to precisely predict how varied materials would behave during the folding process, which has been critical in progressing from prototype to industrial scale production.

Find out more about STILFOLD >>