Harnessing The Power of AI to Revolutionize Engineering Simulation

For some products, multiple physics simulations are essential for design improvements and real-time performance prediction. Multi-physics simulations, which couple various physics, are crucial for designing optimized components and systems. A good example is designing electric machines, where optimized electromagnetic performance and structural and thermal integrity are all interrelated.

What can AI offer engineering simulations? The answer is, a lot!

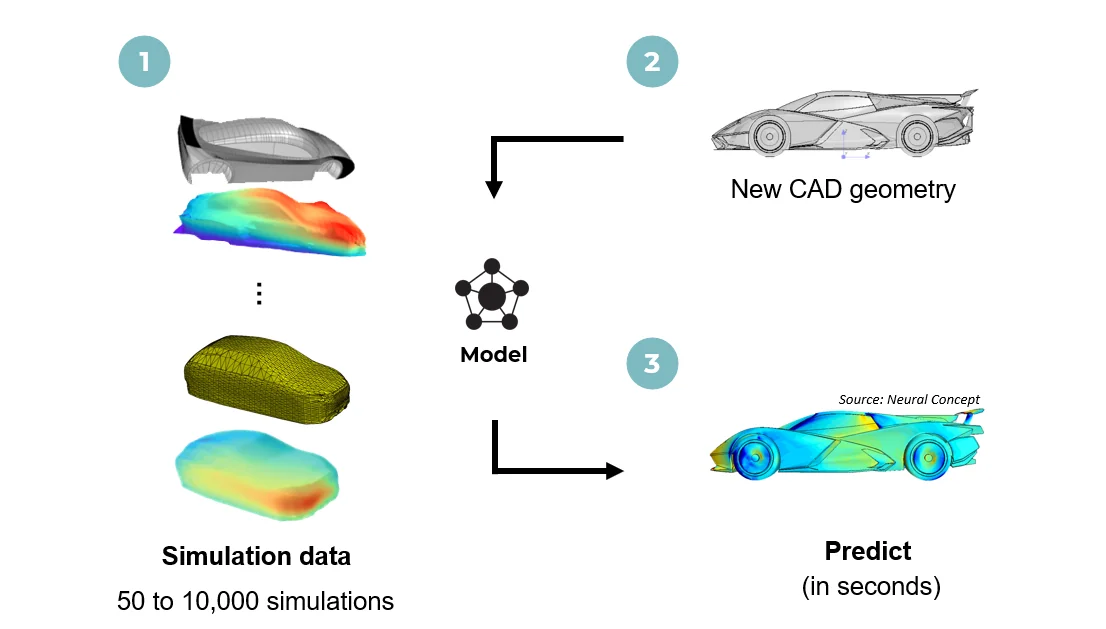

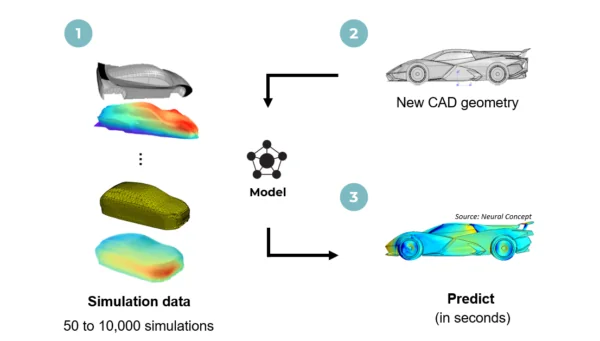

The advent of AI, particularly deep learning neural networks, suggests an impending paradigm shift. These models, commonly used in computer vision, are trained with simulation or test data. They are physics-agnostic and rely on shapes rather than parameters, making them versatile and powerful tools for engineering simulations.

AI enables rapid training on simulation data, leading to new simulations and design optimizations executed with unprecedented speed. For example, heavy computational fluid dynamics (CFD) simulations for optimizing a vehicle’s aerodynamic performance can take hours or days. An AI-generated model can produce these results in seconds, significantly accelerating development.

Pretty amazing, isn’t it? And this is the revolution we are talking about.

Once trained, AI models can be efficiently used by non-expert users, contributing to the democratization of simulations. The number of simulations needed to train the AI model depends on the design space’s size. For instance, an AI model for designing sedans, station wagons, and SUVs requires more training data than one for just SUVs. These AI models also provide a confidence score indicating the reliability of the results.

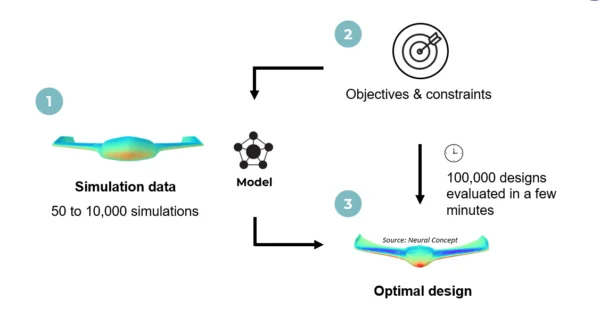

With AI models capable of rapid simulation, the next step is optimization. Hundreds of thousands of designs can be quickly evaluated to find the most optimized.

Let’s have a look at a couple of case studies where AI models are used to generate simulation results and to optimize the performance:

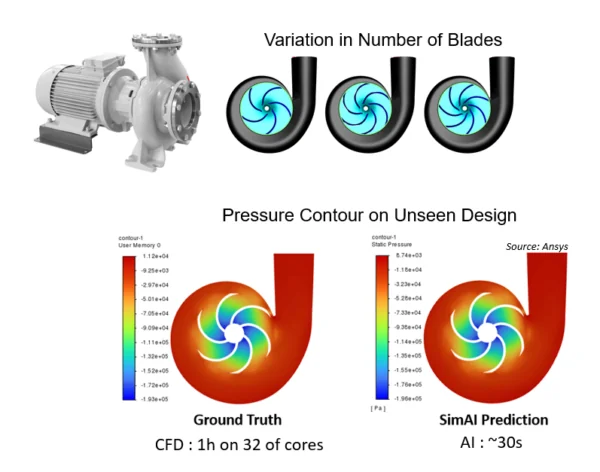

Performance of a centrifugal pump depends on the number and shape of the blades. In this case study, the AI model is trained with 113 CFD simulations that include variations in leading and training edge angles and the number of blades. Here we are interested in pump torque and efficiency values, as well as pressure and velocity fields.

The AI model can successfully generate simulation field results for the new design, with predicted torque and efficiency values in good agreement with high fidelity CFD simulations (less than 0.5% error).

As mentioned earlier, we need to consider a combination of electromagnetic, thermal, and structural aspects when designing electric machines. This case study presents optimization of a synchronous reluctance motor where we want to maximize the torque while minimizing torque ripples.

Several electromagnetic, thermal, and structural constraints are considered in the optimization process. The AI model is trained with Multiphysics simulation results and generates the optimized designs.

A key part of the process is optimizing the shape of the flux barriers which can significantly affect both electromagnetic performance and structural integrity.

The introduction of AI, specifically deep learning neural networks, promises to revolutionize this field by significantly accelerating design and optimization processes. AI models, once trained on extensive simulation data, can perform simulations rapidly, enabling quicker iterations and more efficient design cycles. This democratization of simulation tools also allows non-expert users to leverage advanced simulation, broadening the accessibility and application of high-fidelity simulations.

This article is based on the keynote presentation at the Underwater Technology Conference at Grieghallen in Bergen, Norway, held from June 11 to 13, 2024.

At this year’s UTC, EDRMedeso participated as a keynote speaker, where Mostafa Valavi delivered a presentation titled “Harnessing the Power of AI to Revolutionize Engineering Simulations” showcasing the potential of AI to transform the field.

UTC is an annual event focused on the latest developments and innovations in underwater technology, particularly within the offshore and subsea industries. It brings together professionals, researchers, and companies from around the world to share knowledge, present research findings, and discuss emerging trends and challenges in underwater technology.

Read about the Pivotal role of Electric Machnines in Our Sustainable Future