How to Improve the E-Motor Design Process

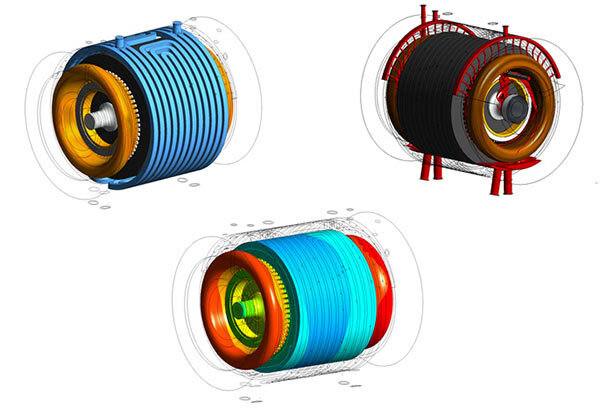

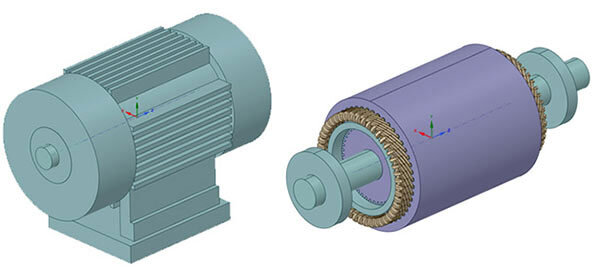

An electric motor is a complex multiphysics system that requires simulation from the start to achieve an optimized design. The demand for smaller motors capable of greater power output is driving this complexity. One of the main concerns with providing more power in a smaller form factor is thermal management.

If the temperature is not controlled, materials can exceed their normal operating temperatures and experience phase change, softening, melting, or other forms of degradation. Beyond the obvious safety risks of thermal stresses that can cause fatigue, cracking, and material deformation, modern materials can be expensive. For example, some electric motors use rare earth magnets that can overheat to the point that they become demagnetized.

Learn more about, how Ansys CFD solutions enhance you to make better and faster decisions.

Ansys offers an engineering workflow that progresses from electric motor design sizing options to detailed electromagnetics and thermal and mechanical analyses of the motor. The workflow encompasses mechanical and thermal simulation software, along with Ansys optiSLang process integration and design optimization (PIDO) software.

Combine different physics into a multidisciplinary approach to investigate phenomena more holistically.

Standardize and share simulation processes across teams, allowing simulation novices to gain more direct access to simulation.

Accelerate time-consuming manual searches for the best and most robust design configuration, enabling engineers and designers can gain a better understanding of their design via interactive visualization and artificial intelligence (AI) technologies.

The optiSLang platform connects Ansys, third-party and in-house tools to automated simulation workflows.

Thermal simulation of electric traction motors requires more than one solver, which typically provides greater accuracy at the expense of speed. Co-simulation performance can be significantly improved by introducing metamodels to the solver, which only marginally increases the time to obtain results while improving the quality of the model.

Register for the upcoming webinar “Improvement of Thermal CFD EM-Models by Introduction of FMU Sub-Models” to learn how ZF Friedrichshafen AG applies co-simulation to more precisely evaluate electric traction motor system design. The generation of metamodels is performed by introducing simplified sub-models into an optiSLang sensitivity study and extracting a functional mockup (FMU) directly from optiSLang. The FMU can then be implemented directly into the thermal simulation.