Making Quasi-Static Simulations Simple with Ansys LS-Dyna

Quasi-static simulation sounds technical, but the objective is simple: simulate slow, controlled loading conditions where dynamic effects like inertia and high-speed impacts aren’t the main concern. Think about things like roof crush tests, bolt pre-tensioning, or structural deflection under gradually applied loads.

This kind of analysis is crucial for evaluating the real-world behavior of mechanical systems under long-duration loading. The good news? You can run these simulations efficiently using LS-Dyna’s explicit solver, if you know the right tricks!

Here, we explore how to run quasi-static simulations using LS-Dyna explicitly, and why that approach makes a lot of sense in complex engineering workflows.

LS-Dyna is a full multiphysics simulation solution. Initially developed for short-duration dynamics using explicit time integration, it has grown to include implicit solvers, CFD, thermal, electromagnetic, NVH (noise, vibration and harshness), and more. Everything is wrapped into one cohesive solver environment, so coupling physics doesn’t require separate platforms or multiple inputs.

For quasi-static analysis, LS-Dyna’s explicit solver is surprisingly well-suited. That might sound counter-intuitive, since explicit solvers are often associated with crash or drop tests. But with a few smart adjustments, such as controlling kinetic energy and choosing suitable time steps, you can use LS-Dyna’s speed and stability to model slow deformation very effectively.

To simulate motion or deformation over time, engineers need to solve equations of motion. Implicit and explicit time integration schemes offer different approaches:

Explicit time integration becomes viable for quasi-static problems when the loads are applied very slowly. This minimizes inertia and kinetic energy so even though it’s a dynamic solver, it behaves like a static analysis.

Running a truly quasi-static simulation with LS-Dyna’s explicit solver requires careful setup:

A common method is to start with a fast simulation to debug the model and understand time scale. Then, gradually increase the analysis end time and observe if the results stabilize. If results no longer change with longer runtimes, the solution is likely in the quasi-static regime.

Comparing applied loads with reaction forces also helps confirm quasi-static behavior. If these values closely match, the simulation is not dominated by dynamic effects.

Explicit solvers are constrained by the smallest element in the mesh, therefore the smaller the elements, the shorter the time step. Mass scaling increases element mass artificially, reducing the speed of sound and allowing longer time steps.

Done carefully, mass scaling improves simulation performance without introducing significant error. As long as kinetic energy stays low and inertial effects remain negligible, mass scaling can be a powerful enabler for quasi-static analysis.

Many real-world structures are preloaded (think bolts under tension or press-fitted joints). Simulating these accurately is important for realistic results.

There are two main methods to introduce preload:

[NB Dynamic relaxation can be run with either explicit or implicit solvers and gives more controlled, cleaner initial conditions]

Many engineering scenarios involve stepwise loading: preload, side load, unload, top load, etc. Rather than cram all these into one simulation, LS-Dyna allows restart analysis, where each load stage builds on the results of the previous.

Three restart types offer flexibility:

This modular approach is efficient and lets engineers iterate quickly, especially when load assumptions change.

Quasi-static workflows are supported in Ansys Workbench via LS-Dyna integration. Here’s what makes setup smooth:

Using mechanical’s Workbench interface, engineers can manage model definitions and run sequential restarts, all within a traceable and repeatable environment.

After running the simulation, you’ll want to check energy plots. If kinetic energy remains small compared to internal energy, your analysis is quasi-static.

Plotting reaction forces gives insight into noise and transient effects. A smooth force response and stable displacements over time further indicate success.

You can also experiment with end times. For example, comparing simulations with 0.1s, 0.5s, and 1s load durations will help identify when results stabilize which is an indicator of sufficient time for static behavior.

Simulating slow-load scenarios with explicit solvers brings multiple benefits:

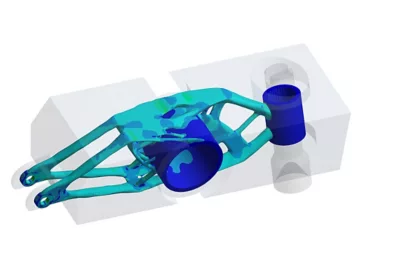

This makes explicit quasi-static analysis especially valuable in scenarios like crash safety, structural collapse, bolt modeling, and rubber deformation.

With smart control of loading rates, mass scaling, and sequential restarts, LS-Dyna’s explicit solver becomes a robust tool for simulating quasi-static problems. You get the best of both worlds: stability, speed, and control, all within a cohesive, multiphysics-ready environment.

And with intuitive setup in Ansys Workbench, even complex simulations like bolt preload and ROPS (rollover protection system) testing become manageable.

Need help getting started or want to explore how this could work in your engineering process?