Ansys Rocky: Redefining Particle Simulation Performance

At the heart of simulation technology lies the ability to replicate real-world physical behavior in virtual environments. One of the most dynamic tools helping to bring simulation to life is Ansys Rocky, a discrete element method (DEM) tool that enables engineers to model and understand the behavior of granular materials in exceptional detail.

The rationale for simulation is simple yet it has the power to innovate and give insight that. Physical testing is expensive, slow, and limited. Creating a virtual test lab allows companies to experiment more freely, iterate faster, and launch products more confidently. This doesn’t just save time and money, it drives innovation, giving teams the freedom to explore.

Rocky began life as a specialized tool for simulating particle behavior, particularly in the mining industry. Over time, it evolved into a comprehensive DEM platform, now fully integrated into the Ansys ecosystem. Today, it supports everything from basic spherical particles to highly complex shapes and flexible bodies like fibers and shells.

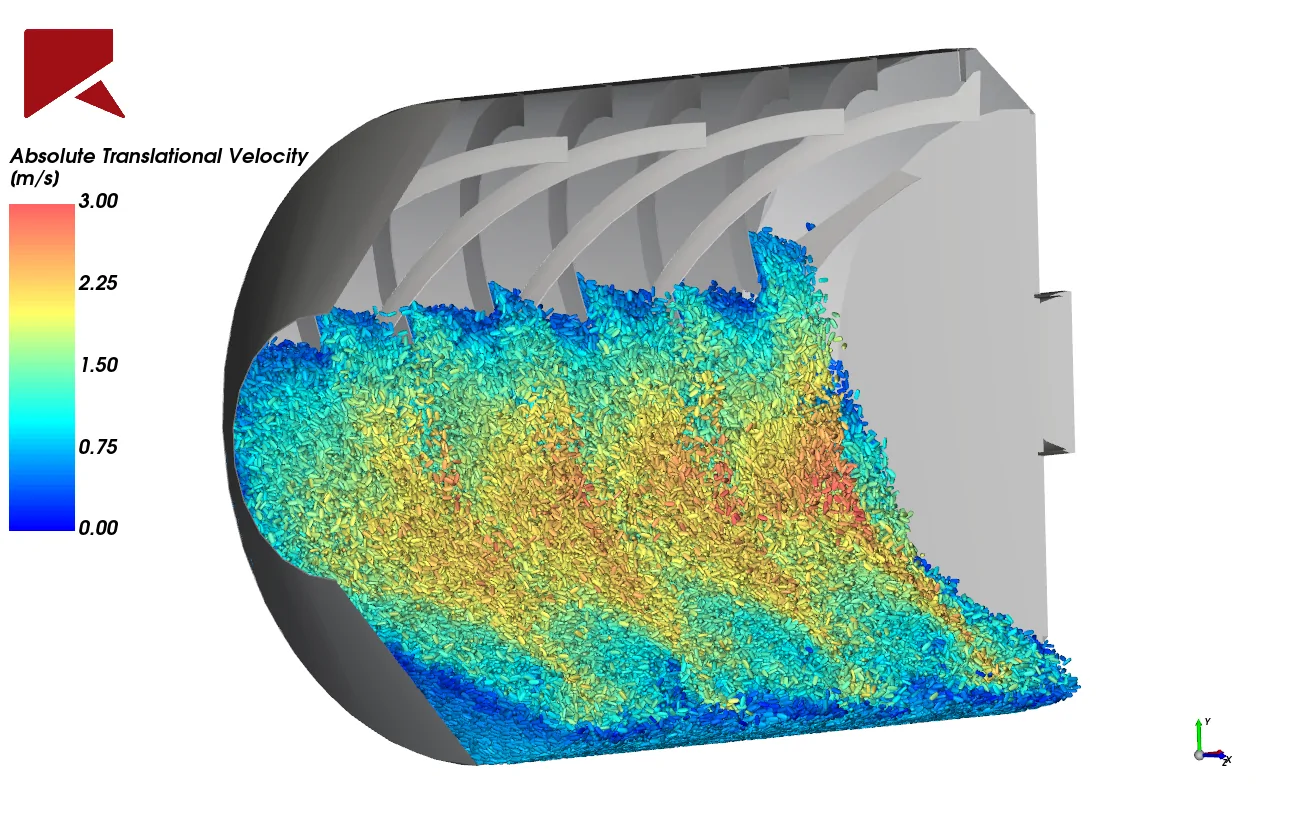

At its core, Rocky allows users to model granular materials, collections of thousands or even millions of particles and analyze how they move, interact, break apart, or wear down over time. These materials show up in virtually every sector: from rocks tumbling through crushers in mining operations, to powders mixing in pharmaceutical production lines, to seeds being sorted in agricultural facilities.

By simulating these processes with high accuracy, Rocky enables users to address critical challenges like clogging, particle buildup, inefficient mixing, and excessive equipment wear. It goes without saying that if left unchecked these problems can cause production delays, high maintenance costs, and even equipment failure.

One of Rocky’s most compelling features is its ability to represent real-world particle shapes. Unlike some traditional DEM tools that rely on simple spheres or ellipsoids, Rocky supports highly detailed particle geometries. Whether it’s jagged rocks, potato chips, or flexible polymer fibers, Rocky can take non-uniform particles in its stride.

Users can choose from a library of default particle shapes, modify them based on aspect ratio or surface detail, or even import 3D-scanned models as STL files. This allows for simulations that not only look more realistic but also behave more realistically, capturing the complex inter-particle forces that define bulk material behavior.

For users dealing with wet or cohesive particles, Rocky includes models that simulate liquid bridges and moisture-driven clumping. This is particularly useful in scenarios like tablet coating or moist powders where stickiness can lead to flow issues or product inconsistencies.

Rocky’s developers were among the first to recognize the value of GPU acceleration for DEM simulations. Because of the software’s highly parallel nature where millions of particle interactions are tracked at once, it thrives on GPU architecture. This results in lightning-fast simulations, even for large-scale scenarios.

Whether it’s a conveyor full of crushed ore or a tablet coating drum spinning at high speed, simulations that once took days can now run in hours. And with multi-GPU support, Rocky scales effortlessly with your hardware investment.

To illustrate Rocky’s versatility, consider a few real-world applications.

One of the most popular use cases is simulating cone crushers in mining operations. Rocky can model how rocks are fed into the crusher, how they break apart, and how the resulting forces affect the structure of the crusher itself. By analyzing this data, engineers can improve throughput, reduce wear, and extend the life of the machine.

In the food industry, Rocky has been used to model the seasoning process of potato chips. This might seem niche, but the challenge is real: ensuring even coating distribution on fragile chips while minimizing breakage. By simulating the drum motion, chip behavior, and seasoning flow, manufacturers can fine-tune their processes for optimal results.

In pharmaceuticals, Rocky is especially effective in mixing and coating scenarios, where uniformity is crucial. The software allows engineers to observe mixing patterns, analyze coverage levels, and even simulate how particle size or moisture content affects final product quality.

Rocky is also a powerful tool for analyzing wear and tear. For example, in milling applications, the software can simulate how liners inside the mill wear down over time, affecting particle flow and efficiency. With its advanced wear models, Rocky allows users to accelerate time within the simulation parameters, showing how wear progresses over days, weeks, or even months.

One of Rocky’s greatest strengths lies in its tight integration with the wider Ansys solutions portfolio. This means you can couple your DEM simulations with structural (FEA) and fluid (CFD) analyses for a more comprehensive understanding of your system.

When paired with Ansys Mechanical, Rocky enables both one-way and two-way coupling. You can simulate how particle loads affect structural components, like a crusher mantle or a conveyor frame, and then bring those deformations back into Rocky to see how they alter material flow.

On the CFD side, coupling with Ansys Fluent allows for detailed simulations of particle-fluid interactions. For example, in a cyclone separator, Fluent can model the airflow while Rocky simulates the behavior of particles as they are carried, separated, or deposited by the flow. One-way coupling lets the flow influence particle movement, while two-way coupling enables full interaction between phases.

For faster simulations, Rocky offers a porous media approach, ideal for pneumatic transport or drying systems where fluid-particle coupling is important but not particularly complex.

One of the most exciting recent developments in Rocky is the integration of Smooth Particle Hydrodynamics (SPH), a meshless CFD approach that enables fluid simulations without the need for traditional solvers like Fluent. In SPH, fluids are modeled as particles with fluid-like properties, allowing for fully coupled simulations within Rocky itself.

This opens up new possibilities for simulating lubrication systems, cooling of electrical motors, or even complex mixing scenarios involving both solid and liquid phases.

For simulations to be meaningful, they must be grounded in accurate material data. Rocky helps with this by offering a guided Material Wizard, where users can input simple test data to estimate key properties like friction, cohesion, and restitution.

In addition, Rocky includes a calibration suite with prebuilt test decks for common validation scenarios. A classic example is the angle of repose test, where particles are poured into a pile and the resulting slope is compared to experimental results. By matching simulation output with physical benchmarks, users can fine-tune input parameters to ensure simulations reflect real-world behavior.

From mining and manufacturing to food processing and pharmaceuticals, Ansys Rocky is helping engineers simulate the complex world of particles with greater precision than ever before. Its ability to model breakage, wear, motion, heat transfer, and fluid interaction makes it one of the most versatile DEM tools available.

As simulation becomes more central to product development, tools like Rocky aren’t just helpful, they’re essential. By giving engineers the power to predict and optimize performance before a single prototype is built, Rocky transforms how we design, test, and deliver products.

If you’re curious about how Rocky can be applied to your specific workflow or would like to learn more about simulation in general, feel free to reach out.