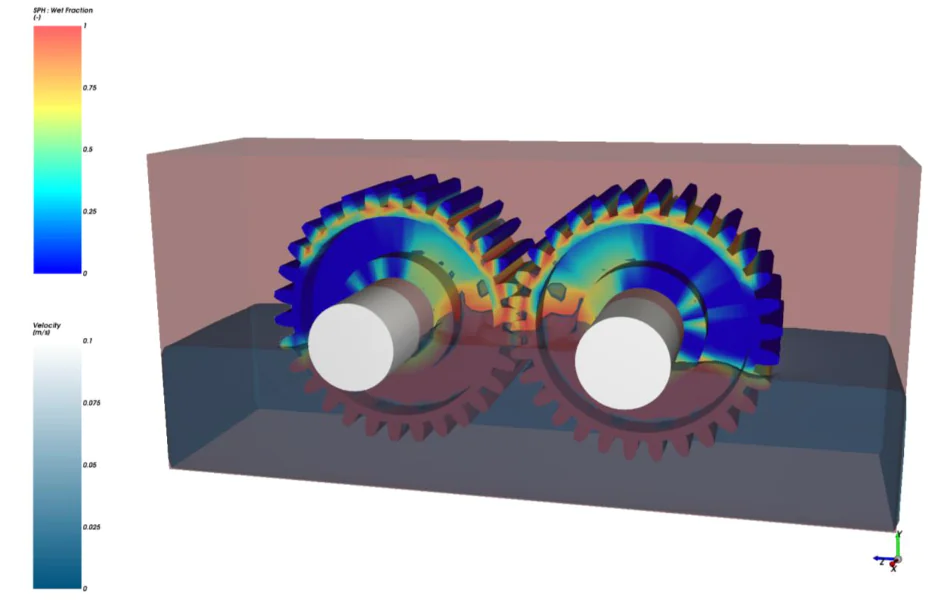

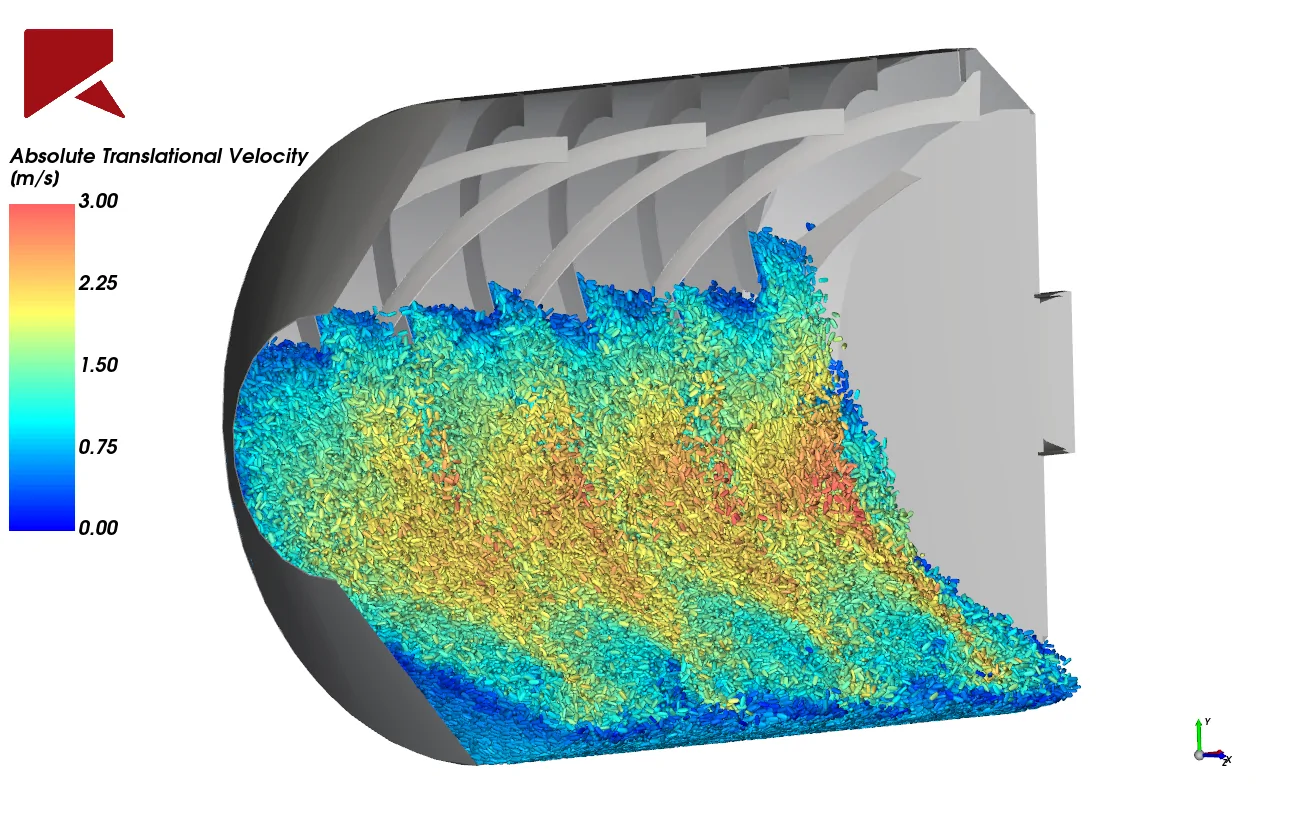

With Ansys Rocky™ (particle dynamics simulation software), engineers can simulate and analyze the behavior of particles in a wide range of applications, such as pharmaceutical manufacturing, chemical processing, mining and mineral processing, and food processing.

Simulating the Behavior of Particulate Materials

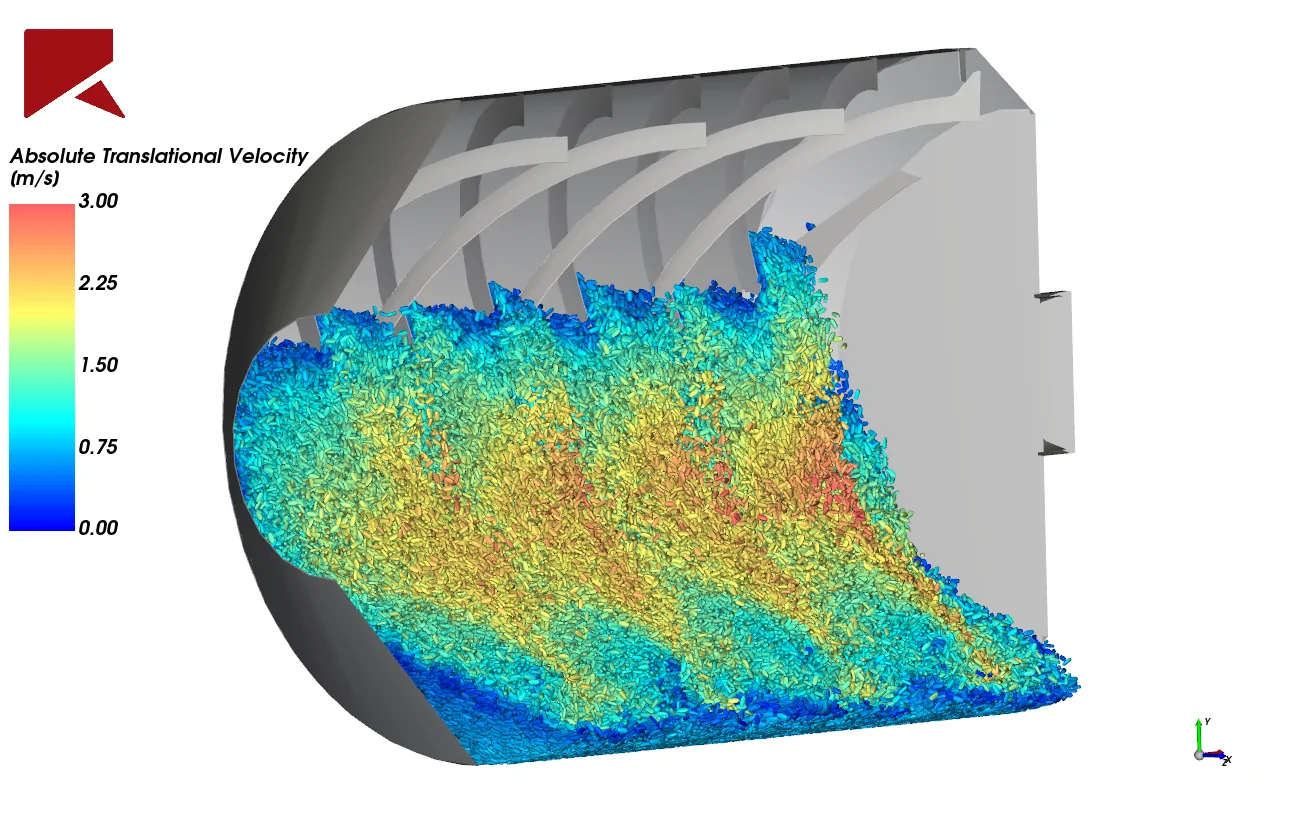

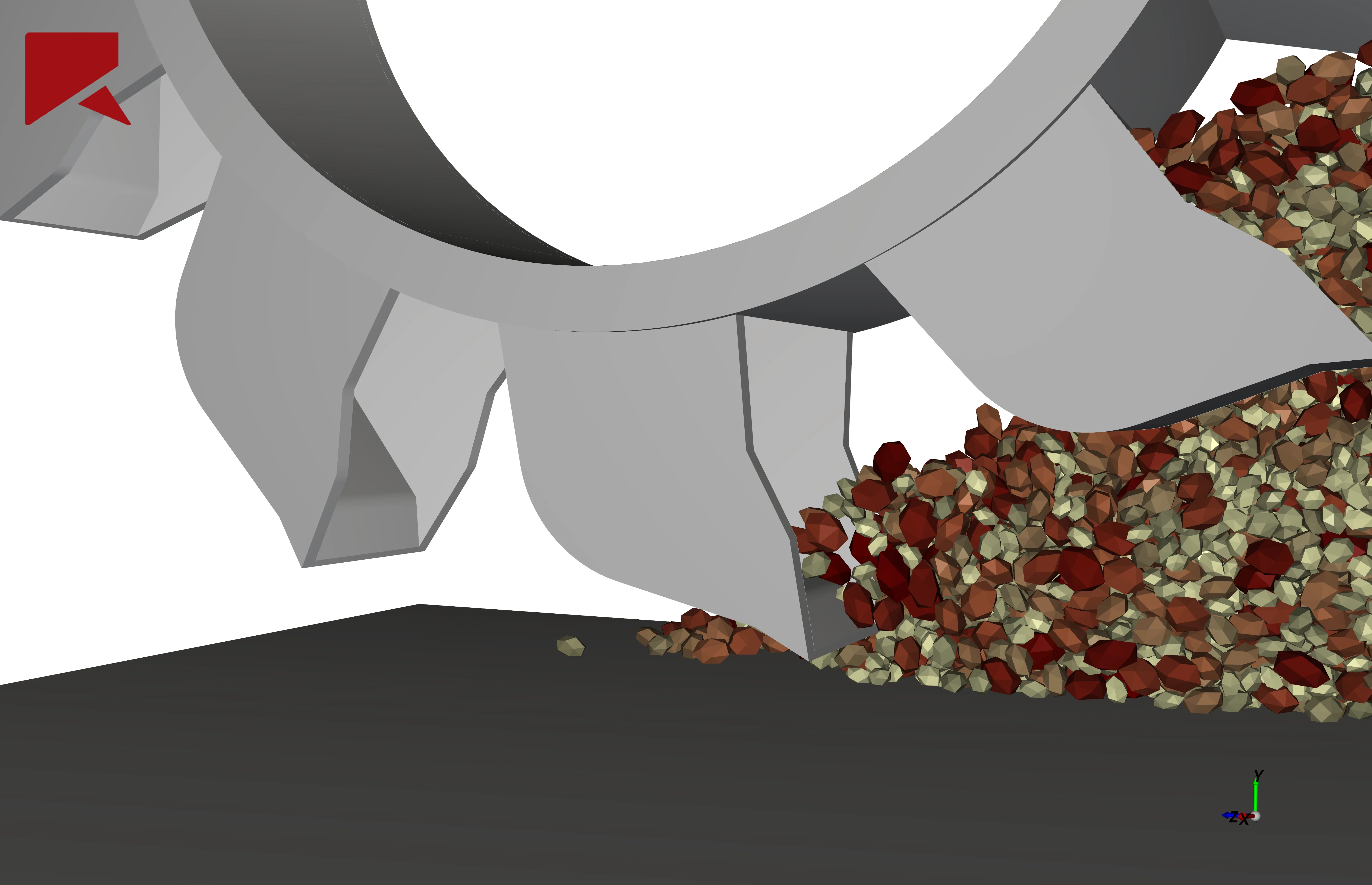

Ansys Rocky™ is a powerful simulation software used for simulating the behavior of particulate materials, such as granular materials, powders, and tablets, under various conditions. It is based on the Discrete Element Method (DEM), which uses a particle-based approach to simulate the interaction between particles and the surrounding environment.

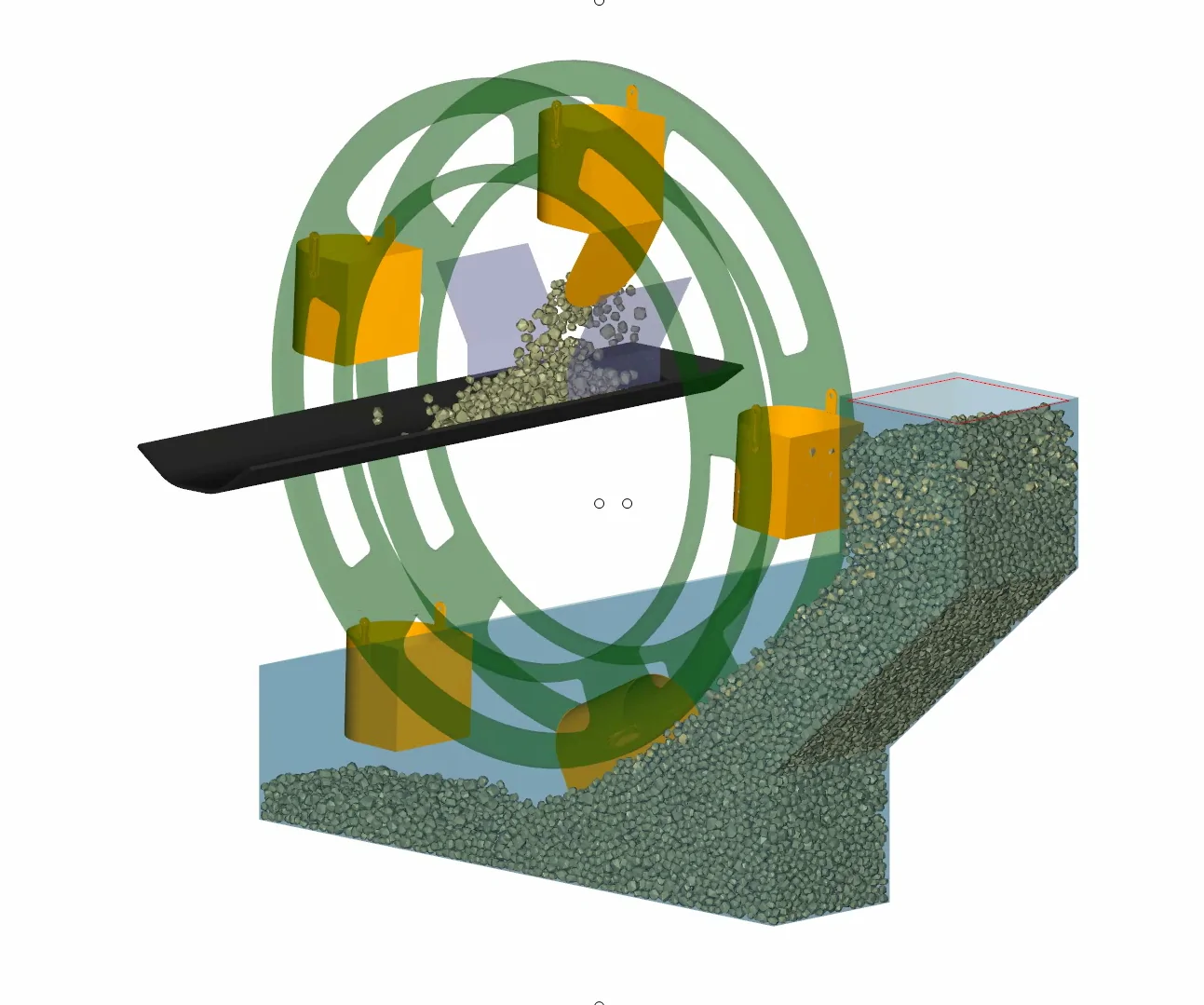

The capability to use real particle shapes including any solids, 2D shells, and rigid and flexible fibers is unique for Ansys Rocky™. With multi-graphics processing unit (GPU) solver technology, you can simulate the behavior of different shaped and sized particles in many industrial applications.

Key Features

Ansys Rocky™ is the premier tool for quickly and accurately simulating the behavior of bulk materials with complex particle shapes and size distributions.

- Multi-GPU Processing

- Realistic, Complex Particle Shapes

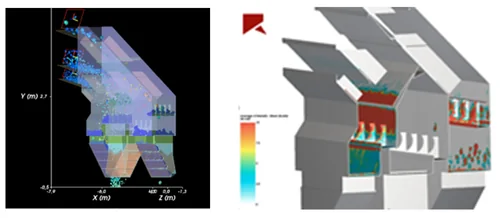

- Fluid Mechanics Coupling

- Structural Mechanics Coupling

- Electromagnetic Coupling

- Multibody Dynamics

- Breakage Modeling

Benefits

Case Study

Particle Analysis and Cloud Computing Produce Mining Solutions Built to Last

In the mining and aggregates industry, a company can move hundreds of thousands of tons of material every day. The right equipment can help increase productivity, optimize energy usage, reduce cost-per-ton, improve safety, and avoid risks. From the perspective of one equipment developer, Metso Outotec, dependability is key.

Speak to an Expert

Reach out to our expert for help or advice

Over the years the focus has shifted from working primarily in the support team to the presales team, supporting the sales process. The sales process is also developing rapidly and instead of purely focusing on specific tools I promote the full portfolio of products that we utilize to assist the whole product development process.