Ansys Sherlock™ an electronics reliability prediction software, is the industry-leading reliability physics and failure analysis software that helps engineers predict and prevent electronics failures in complex systems.

Product Life Prediction

With Ansys Sherlock™, you can quickly and accurately identify potential points of failure in electronic devices, allowing them to make informed decisions about product design and reliability. Its advanced algorithms and simulation capabilities enable you to simulate and analyze the behavior of electronic systems under various stress conditions, such as thermal cycling, vibration, and shock.

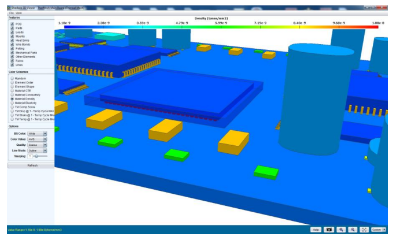

In post-processing simulation results from Ansys Icepak® (electronics cooling simulation software) and Ansys Mechanical™ (structural finite element analysis software), and Ansys LS-DYNA® (nonlinear dynamics structural simulation software), Ansys Sherlock™ can predict test success and estimate warranty return rates. Users are more efficient by directly connecting simulation to material and manufacturing costs.

Key Features

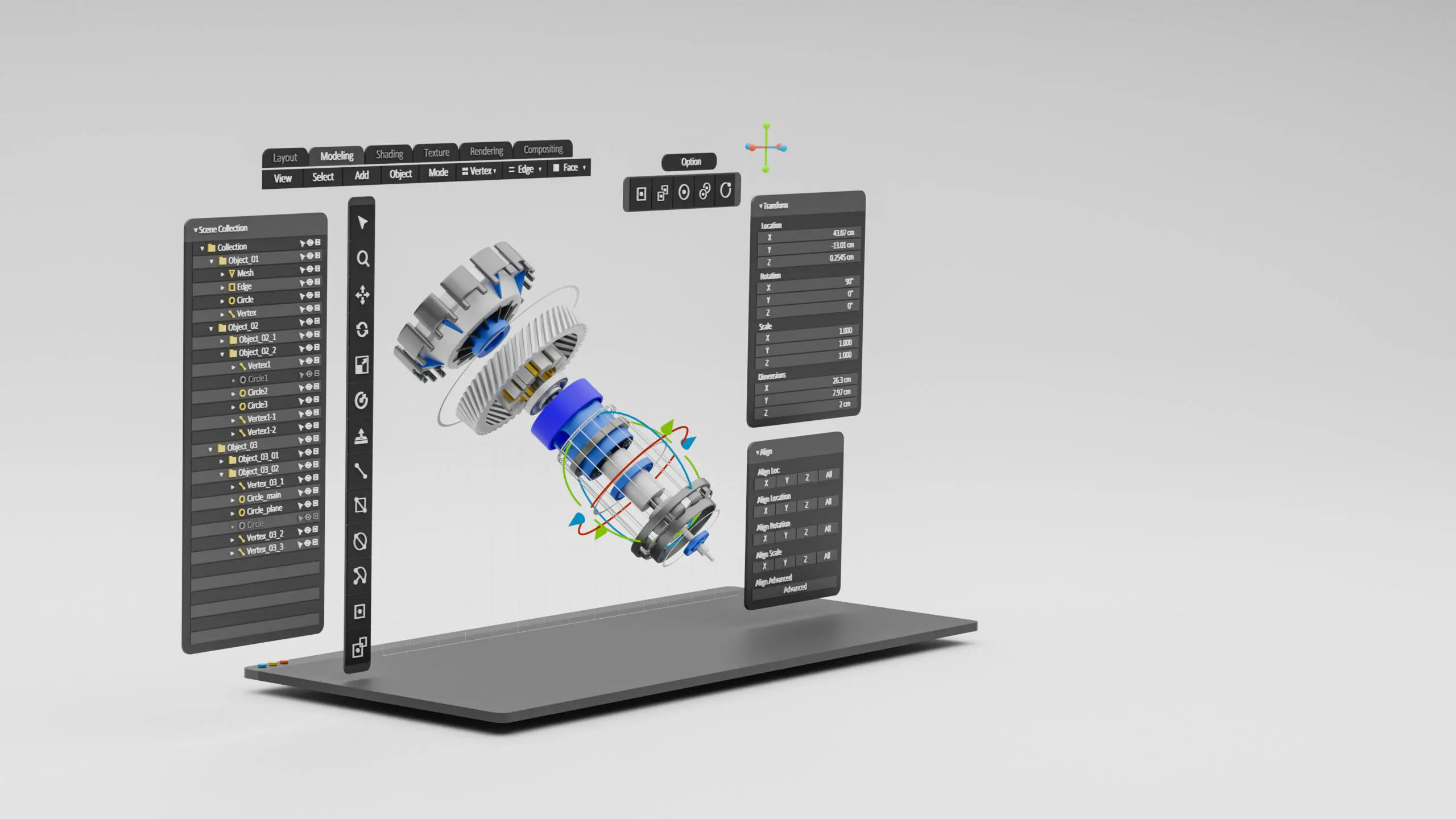

Ansys Sherlock™ uses your own design files to build 3D models for electronic assemblies for trace modeling, post-processing, and reliability predictions.

- Builds and tests virtual products

- Modifies designs in near real-time

- Quickly runs mechanical simulations

- Evaluates and optimizes design choices

Benefits

Reduced Risk of Product Failures

Enhanced Product Performance

Intuitive User Interface

Improve Quality and Durability

Case Study

Danfoss A/S Reduces Time to Market for AC Drives by 75%

Danfoss sought continued innovation of their AC drives with the goal of reducing energy waste. Considering the thousands of variants of utilization for AC drives, Danfoss wished to improve the efficiency of their AC drives without sacrificing the abundance of deployment methods.

Speak To An Expert

Reach out to our team