Empowering Innovation: Quintus Uses Ansys Simulation to Solve High-Pressure Challenges

Quintus Technologies is a global leader in high-pressure technology. The company designs, manufactures, installs, and supports high-pressure systems in three main areas: densification of advanced materials, sheet metal forming, and high-pressure processing for food and beverage innovation, safety, and extended shelf life.

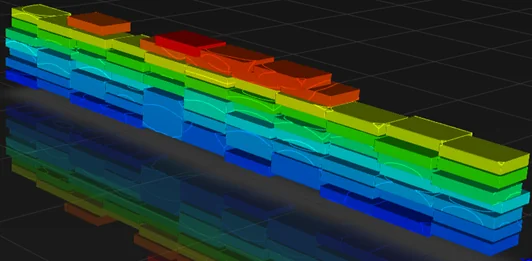

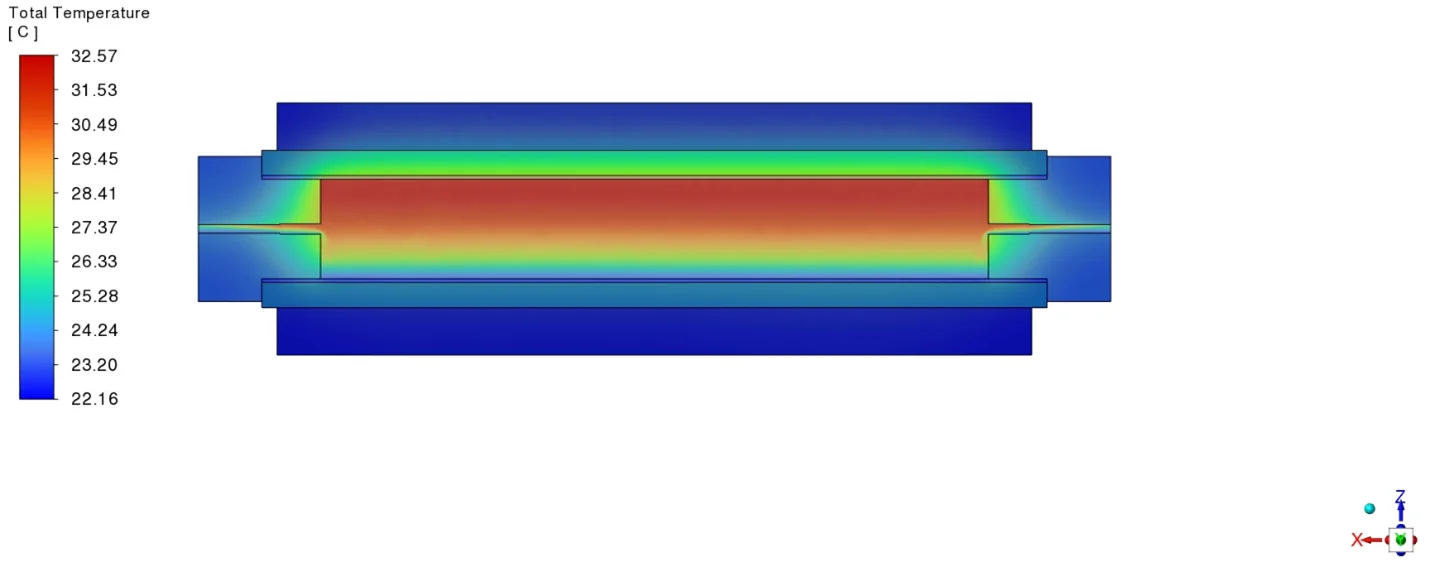

One standout offering from Quintus is their battery presses. With typical pressures ranging from 800 to 6,000 bar (11,603 to 87,022 psi) and temperatures up to 150°C (302°F), isostatic pressing enhances contact between components in solid-state battery cells. This process reduces resistivity, increases power density, and supports the production of essential components for next-generation battery technologies.

Quintus Battery Press Machine, QIB 180

Quintus is driving a niche market that faces multiple challenges such as:

To expand the adoption of their technology across industries, Quintus must address these challenges while proving reliability and building customer trust. Physical testing, however, is often impractical, expensive, or impossible due to the extreme environments and associated risks.

Quintus uses Ansys simulation technology to address these challenges effectively. Advanced simulation tools, combined with physical testing, allow Quintus to analyze thermal phenomena, optimize designs, and troubleshoot problems. These tools also enable the creation of design proposals during construction, providing customers with solid evidence to trust Quintus solutions.

By partnering with EDRMedeso, Quintus has gained additional resources in terms of simulation engineers and access to software and hardware, increasing capacity for larger computational tasks.

Quintus uses simulation extensively for new designs, particularly in high-pressure environments where physical prototypes are not yet available. In this context, simulation is critical to demonstrate that specific conditions can be met. To access a variety of software licenses for evaluation, Quintus utilizes the EDRMedeso tech pool, to gain flexibility to test and identify which tools best meet their needs. The most used technologies are Ansys CFX, Fluent, and Mechanical.

Accelerated and Trustworthy Product Design Process

Quintus has been building isostatic presses since the 1960s, accumulating deep expertise in the field. Simulations not only offer opportunities to further develop their products but also allow Quintus to efficiently evaluate and select optimal design paths, accelerating the process of bringing products to market.

Simulation offers several key advantages such as:

Time savings: Virtual prototypes enable faster testing, with results verified during implementation.

Improved safety and reliability: By modeling high-pressure environments, Quintus ensures safety and reliability without the risks of physical testing.

Long-term efficiency: Insights gained from simulations can be applied to future projects, enhancing overall innovation and efficiency.

Control over intellectual property: Performing simulations in-house ensures that Quintus retains full control over its intellectual property, which is a critical advantage in a competitive market.

Building trust: Reliable simulation data strengthens customer confidence in Quintus solutions.

Through its partnership with EDRMedeso, Quintus benefits from expert consultation and flexible resource support, enabling the company to address specific challenges and explore new opportunities.

The support is highly utilized, and one of the best things about it is that it responds quickly. Additionally, the tech pool (access to new simulation technology for evaluation) is greatly appreciated. – Anton Fritz, R&D Engineer, CFD at Quintus Technologies

Learn more about Quintus Technologies

Explore Career Opportunities at Quintus