Enhancing Offshore Structural Integrity with Engineering Simulation

Company Background

Company BackgroundFS Dynamics Europe’s leading CAE Simulation Consultants providing services for simulating systems, processes and equipment involving fluid analysis, structural analysis, vibration and acoustics. With two decades of proven success in simulation, FS Dynamics cooperates with a large number of customers all over Europe to deliver better and more robust solutions faster in a timely manner. Committed to provide high quality services for product and process development its scope encompasses all industries, such as wind and nuclear power, automotive, offshore, marine and life science.

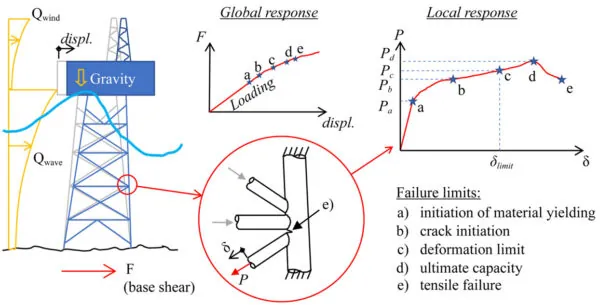

Offshore steel structures, such as platforms and rigs, are exposed to extreme environmental conditions, including powerful wave loading, harsh winds, and corrosive marine environments, see Figure 1. These factors can compromise the structural integrity of the platforms over time, increasing the risk of unexpected failures, costly repairs, and operational downtime.

Figure 1: Global and local load-deformation responses. Local failure limits visualized in the local load(P)-deformation(δ) response curve.

The core business challenge is ensuring that these structures can withstand these forces while operating reliably and safely over their expected lifespan. This is critical for maximizing asset up-time, minimizing maintenance costs, and avoiding catastrophic failures that can disrupt operations, cause safety hazards, and incur significant financial losses.

As offshore industries continue to grow, with increasing pressure to operate more cost-effectively and sustainably, the ability to predict, analyze, and mitigate these risks is more crucial than ever. The ability to deliver reliable, high-performing offshore assets, while minimizing operational interruptions and reducing long-term costs, is a key competitive advantage in the industry.

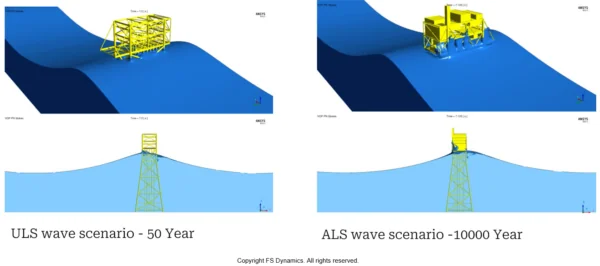

Engineering simulation offers an advanced, cost-effective solution to the challenges faced by offshore steel structures. Traditional methods, such as physical testing and simplified analytical models, are often too limited, expensive, or time-consuming to evaluate the complex interactions between waves, structural elements, and environmental forces. By using Ansys Fluent, Ansys Mechanical and Ansys LS-DYNA, engineers can accurately simulate how offshore structures will perform under a wide range of conditions, including extreme weather events, such as fatigue, ultimate and accidental wave loading events as shown in figure 2, and cyclic stress events.

Figure 2: Examples of ultimate and accidental wave loading events simulated with Ansys Fluent.

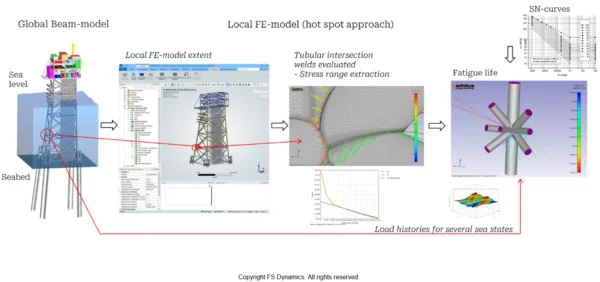

These simulations enable the precise modelling of fluid-structure interactions (FSI), allowing engineers to assess structural responses, identify potential failure points, and optimize designs for maximum strength, durability, and performance. The ability to simulate various scenarios with high accuracy not only helps reduce the risk of failure but also eliminates the need for costly and time consuming physical testing. Simulation allows companies to explore multiple design alternatives, making it easier to optimize structure designs and maintenance plans. This ensures the structures remain operational over the long term, reducing the need for unexpected repairs due to fatigue and minimizing operational costs (see figure 3).

Figure 3: Examples of Fatigue evaluations involving Ansys Mechanical.

Furthermore, simulation supports regulatory compliance, ensuring that offshore structures meet safety and performance standards while providing companies with critical insights that drive smarter, more informed decision-making.

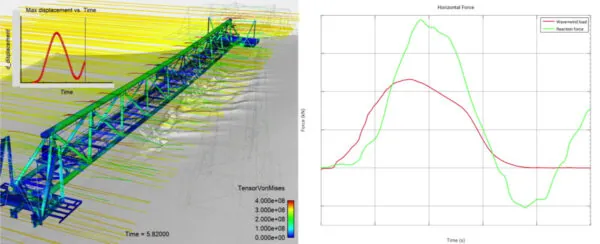

The primary advantage of engineering simulation lies in its ability to deliver highly accurate predictions of how offshore structures will behave under real world conditions, allowing for better-informed design and operational decisions. By using FSI simulations, engineers can identify stress concentrations, areas of fatigue, and potential failure points – insights that are difficult to achieve through traditional methods. This deep understanding of the structure’s response enables engineers to design for resilience, optimizing materials and configurations to ensure long-term durability. Additionally, simulation can be used to predict the impact of various extreme events, such as severe wave loading, storms, or even accidental damage, ensuring that the structure will perform safely under such conditions (see figure 4).

Figure 4: Examples of FSI analysis involving Ansys Fluent and Ansys LS-DYNA. Ansys Ensight is used to visualize extracted results.

From a business perspective, engineering simulation brings significant cost savings by reducing the need for extensive physical testing, minimizing unplanned downtime, and extending the operational life of offshore platforms. By identifying vulnerabilities early in the design process, simulation helps avoid costly repairs and unanticipated failures, reducing both operational and maintenance costs. It also provides a clear pathway for efficient, proactive maintenance scheduling based on precise, data-driven predictions, ultimately ensuring that offshore assets stay in operation longer.

Additionally, simulations improve risk management by offering better forecasting of structural performance, enabling companies to make proactive, rather than reactive, decisions. With improved safety, reliability, and performance, companies benefit from a more predictable and profitable operation.

In summary, engineering simulation enables businesses to meet both their engineering objectives and broader business goals – such as cost reduction, improved asset up-time, and enhanced operational efficiency – while ensuring safety and regulatory compliance.