Hystar: how simulation is helping industry experts extend insight, assess performance and analyse safety in innovative PEM electrolysers

Green hydrogen is key to the transition toward renewable, more sustainable energy sources and in combating greenhouse gas emissions.

Scaling up electrolysis technologies to meet the demands of a greener industry is a significant global challenge. Numerous technical complexities need to be overcome to meet electrolyser development goals in terms of performance, efficiency, scalability, and cost. Specifically, for Hystar, shortening development time was a high priority, thereby reducing time-to-market.

Ansys simulation tools were selected as a strategic solution to accelerate the development process, enhance confidence in design before manufacturing, and ultimately reduce the overall cost of tests. They offered a controlled environment for iterative testing and refinement, enabling Hystar to streamline the development cycle.

Ansys gives Hystar the ability to provide accurate results and with the potential to implement workflow tools that facilitate faster and more convenient modeling. Simple integration with a variety of CAD tools was crucial to ensure an efficient development process.

Hystar was partly founded by industry experts with a background in PEM electrolyser and fuel cells.

The patented technology that enables its high-performance electrolysers was developed based on 15 years of research. Using simulation has allowed Hystar experts to extend this knowledge by enabling understanding of detailed and highly coupled physical processes. This has not only expanded engineering knowledge but has also contributed significantly to the development of its innovative solutions.

Simulation is a critical requirement for Hystar due to the prohibitive costs and time associated with experimental tests of various design configurations. The need to evaluate design concepts early in the development process is vital to achieving development goals. Simulation allows both design performance and safety assessment early in the design phase, allowing engineers to make informed decisions, swiftly and cost-effectively.

By implementing simulation in the workflow, Hystar was able to assess and compare the performance differences and any trade-offs of various design concepts early in the design process. This not only accelerated the evaluation period, but also significantly reduced costs compared to traditional experimental testing. Simulation continues to deliver valuable insight into the viability of alternative designs, contributing to more informed decision-making.

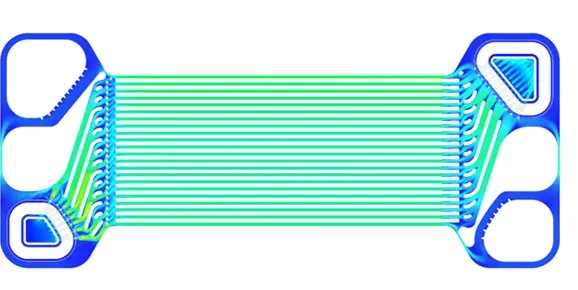

CFD simulation in Ansys Fluent of a Hystar prototype electrolyser bipolar plate

Hystar has been a member of the Ansys start-up program since 2021. Through this program, Hystar engineers and designers have had access to the entire Ansys portfolio of simulation software. Specifically, Ansys Mechanical is utilized to both develop electrolysers and perform structural simulations whilst Ansys Fluent is the solution of choice for fluid-mechanical simulations. In addition, the company uses Ansys Granta for material selection and Ansys Optislang for design optimization.

The ability to perform non-linear structural simulations has been important to designing compression and sealing solutions, and the fluid mechanical solvers for multiphase and multispecies transport has been central to the development of the safe and efficient design of the water, hydrogen and air flow in the electrolyser.

“EDRMedeso has played a pivotal role in supporting our simulation and modeling efforts. Their high-quality training, swift troubleshooting, and guidance have been invaluable. They assisted in setting up Cloud computing platform Rescale for our HPC needs and the self-paced training platform, EDRMedeso TrainingPortal, has enhanced our proficiency with a wide range of simulation software.

We have actively used supporting tools, like CloudConnect, developed by EDRMedeso for seamless management of Cloud simulations. Their assistance has accelerated our learning curve and significantly contributed to our success.”

Knut Ringstad, Analytical Simulation Engineer at Hystar

Simulation software played an important role in the rapid development and high performance of Hystar’s electrolyser platform. By integrating simulation as a cornerstone of the development process, they achieved a faster time-to-market, enabling the company to make well-informed decisions and ultimately design a more efficient product.

Simulations were actively used for many key design decisions, such as sealing gasket optimization, evaluating the pressure drop of two-phase flow in the electrolyser, designing for appropriate electrical conduction, and heat management.

Simulation has presented several advantages in the design work and development processes. Using simulation has made more cost- and time-effective design cycles possible, which has improved decision-making, enabled earlier detection and mitigation of design issues, and yielded more innovative design exploration. Simulation has also helped improve the accuracy of engineering calculations and widened the possibilities within collaborative and multidisciplinary design.