Businesses continue to operate in a fast-paced environment, and staying competitive is a must. In this digital age, leveraging Digital Twin and IoT technology is crucial to optimize operations, make informed decisions, and achieve ESG targets. However, many small and medium-sized enterprises may find implementing Digital Twin technology intimidating, especially without large datasets or dedicated technology specialists.

Adding Value to Your IoT Data

But a pragmatic approach can change this. By integrating off-the-shelf solutions and building upon proven technologies, even companies with limited resources can harness the power of AI and Digital Twins. The use of high-fidelity models and simplified engineering calculations can embed engineering insights into digital twins, providing a valuable resource for decision-making.

One common mistake that companies make is creating digital twin projects that are too complex too soon. Instead, a “start small and scale fast” approach can help companies embrace Digital Twin technology incrementally. Gradually expanding its applications and benefits throughout the development, production, operation, and maintenance.

In addition to practical benefits, it’s essential to remember that AI and Digital Twins can contribute to a more sustainable future. By improving resource efficiency, reducing waste, optimizing energy consumption, and enhancing predictive maintenance, companies can fulfill their social responsibility goals while achieving economic success.

As technology continues to evolve, companies that adopt a pragmatic approach to Digital Twin implementation will have a competitive edge. By starting small and scaling fast, they can achieve operational excellence, meet ESG targets, and create a sustainable future.

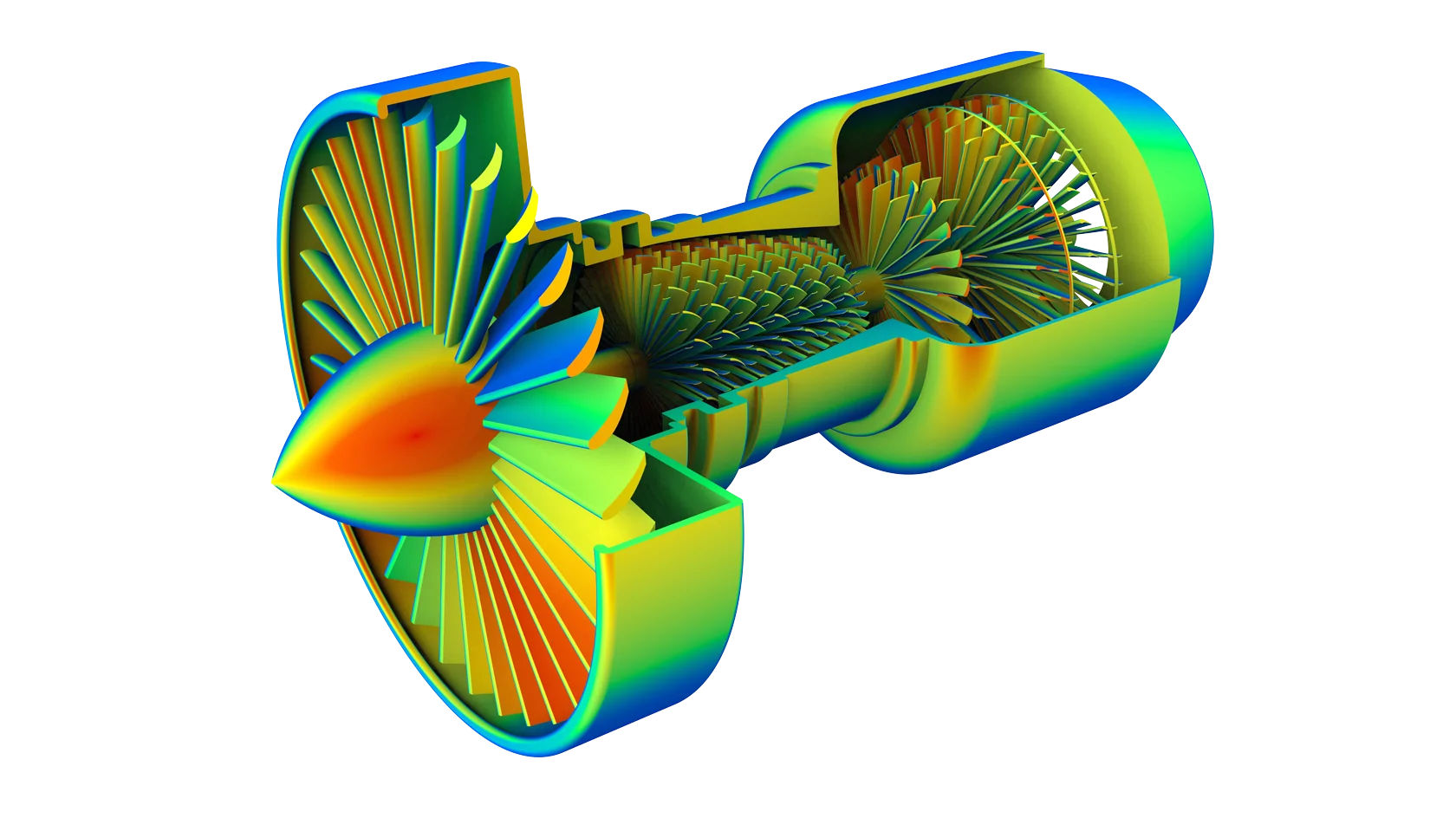

Sensor or control system data is fed from the physical asset to the Digital Twin in real time. The Digital Twin has physics models, engineering know-how and data analytics built in. This enable you to predict the future performance, behavior and maintenance needs.

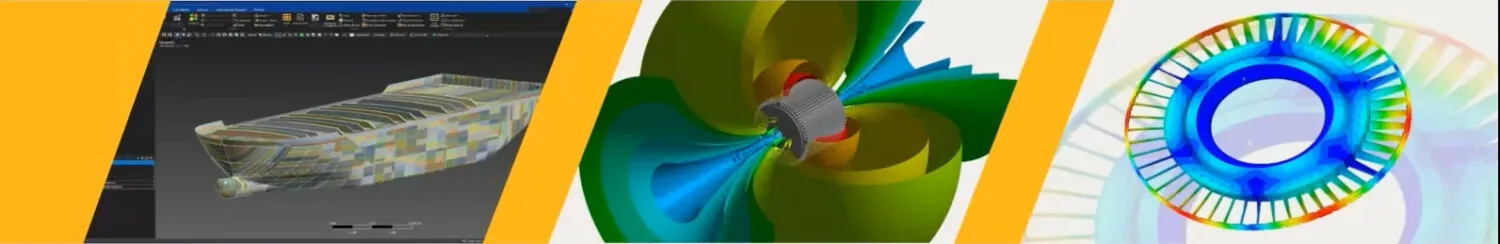

This is not just a dream, or a vision, for the future. Innovative Industrial companies are developing and deploying services like this already today. They are using this technology to be able to do reliable Predictive Maintenance, which again is forming the foundation for bringing new business models to the market.

New business models could for example be selling a service rather than a physical product, by offering a subscription with a guarantee that, for example, this pump will pump 100 cubic meter of liquid per hour with a 98.5% uptime.

Such services cannot be sold without being able to reliably predict the future behavior of your product.