AFRY: Thermal Energy Storage for a Sustainable Future

Storing energy on a large scale is challenging, but heat can be stored and reused, for example, in district heating during the winter. Several thermal energy storages are being built, with capacities in the gigawatt-hour (GWh) range.

Many decommissioned underground storages built decades ago are now planned to be converted into thermal storage. A typical thermal storage can hold between 10–20 GWh of thermal energy.

Stored energy of 10 GWh is enough to supply a mid-sized Swedish city of 50 000 people with district heating for up to two weeks.

The storage medium itself should meet several important criteria: cost-effective, non-toxic, widely available and sustainable, non-flammable, and non-corrosive.

Water meets all these requirements and is naturally present underground, making it a great choice for heat storage, especially since district heating systems already use water in the heat circuit. Water also has a high thermal mass, which means it can store a lot of heat efficiently. The main limitation is that the maximum temperature is limited to about the boiling point of water.

When simulating thermal storages, getting the thermocline right is essential. Some of the challenges include:

The main limitation is that the maximum temperature is limited to about the boiling point of water.

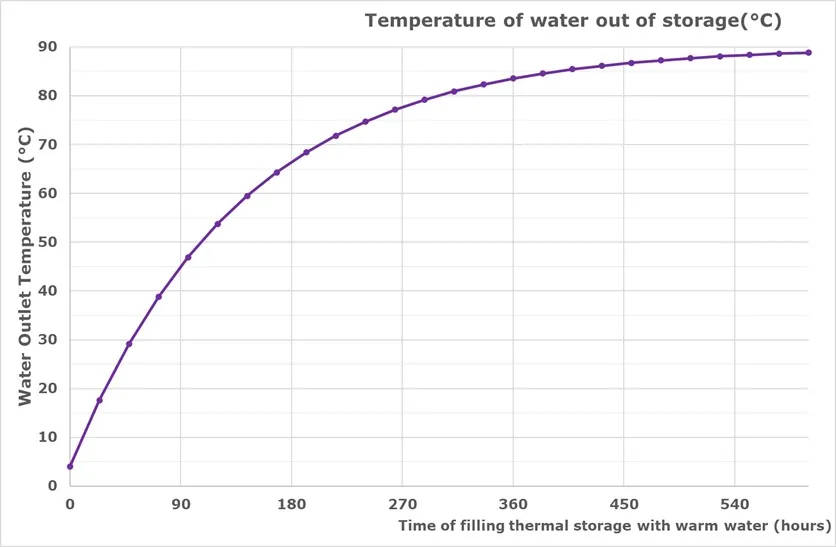

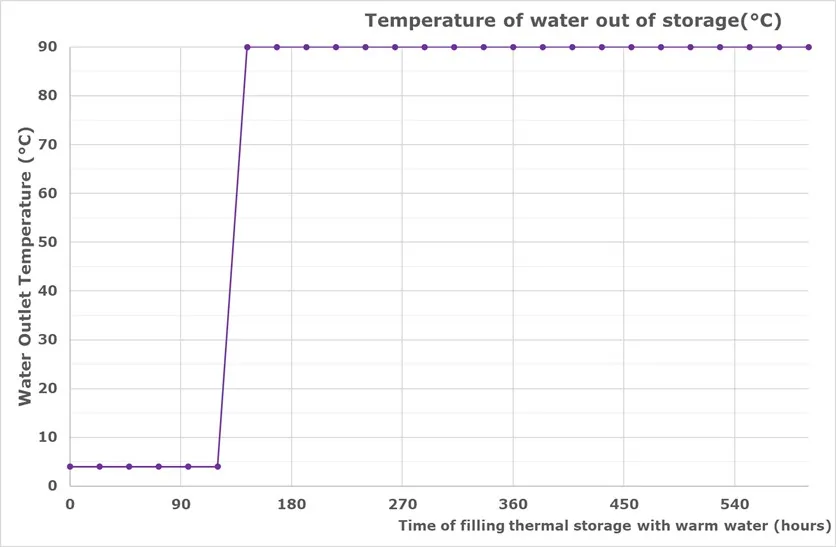

The key to effectively converting excess heat and electricity from renewable sources is to avoid mixing colder and warmer water. An ideal thermal storage should work as a plug flow reactor. When filling the storage with warm water, the outlet should only eject cold water. If the cold and warm water mix, the thermal storage acts more like a continuously stirred reactor. The warm water pumped into the storage is gradually mixed with the cold water. The mixing of cold and warm water generates a lot of lukewarm water with limited usage and decreases the efficiency of the thermal storage.

Stored energy of 10 GWh is enough to supply a mid-sized Swedish city of 50 000 people with district heating for up to two weeks.

An example of a storage volume of 10 000 m³ with an initial temperature of 4 °C: hot water at a temperature of 90 °C and a rate of 7.5 MW is continuously added to the thermal storage.

If the hot and cold water mix, it will take about 25 days for the storage to reach the target temperature of 90 °C. If the thermocline is preserved, the storage will be filled with 90 °C water in about 6 days.

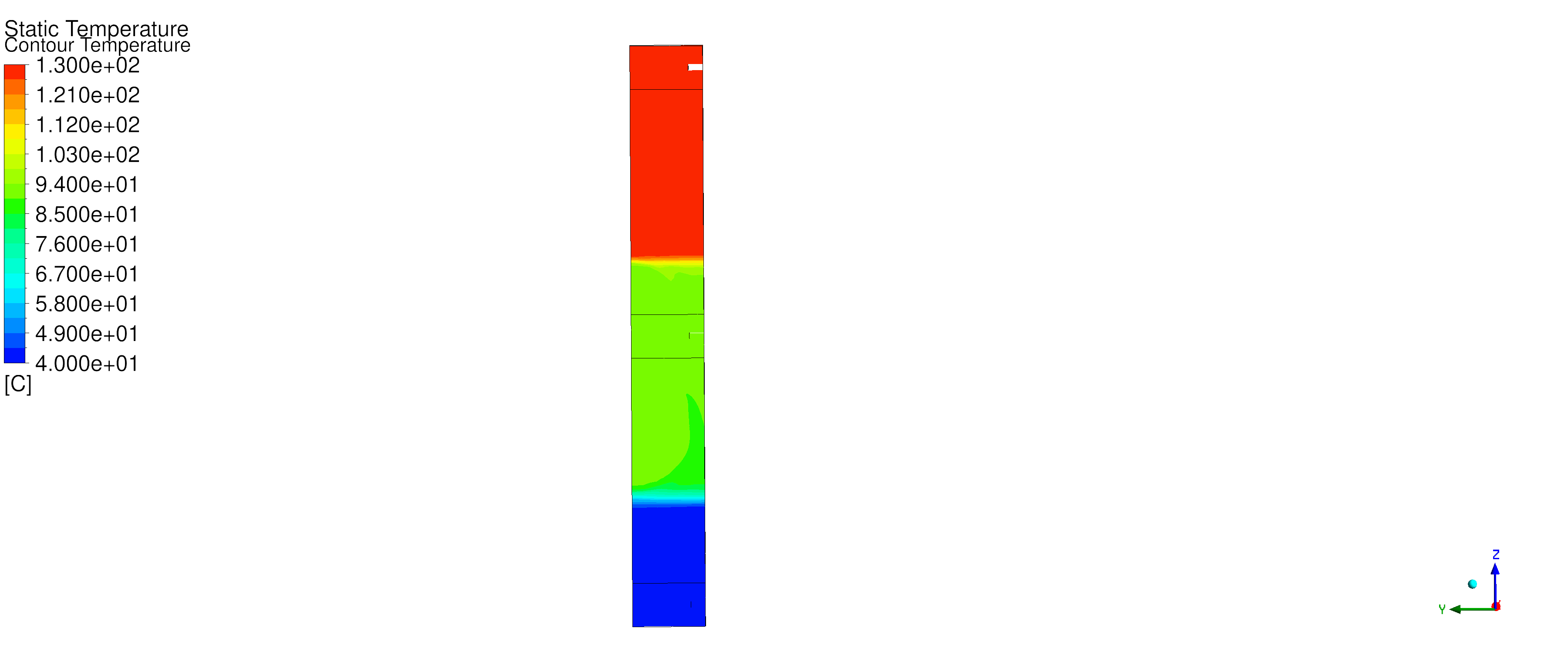

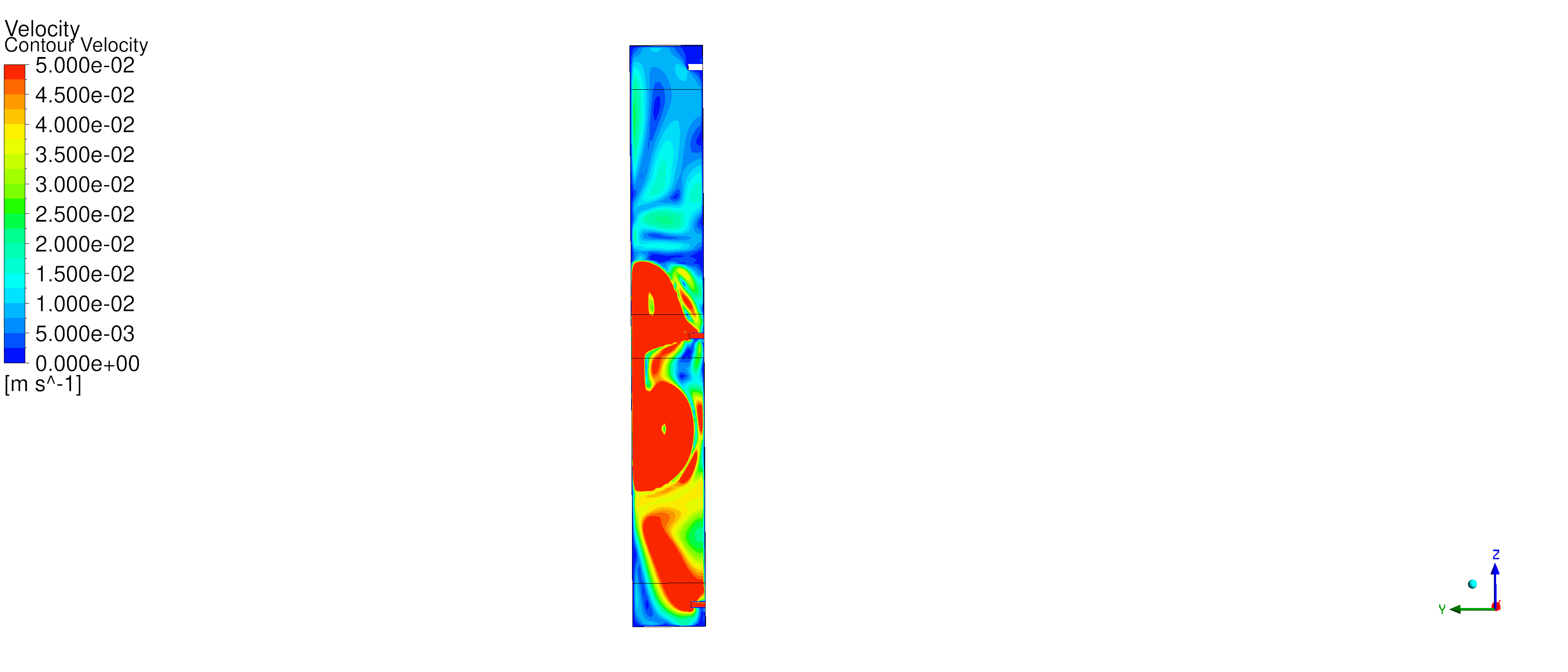

The barrier that prevents mixing of warm and cold water is known as a thermocline. The thermocline is created by the difference in density between warm and cold water. If the flow of water is small, the density difference will prevent mixing across the thermocline. Heat conduction through the thermocline will still cause losses, but these thermal losses are much smaller than those caused by mixing of cold and warm water.

This calculation is simplified and does not take into account losses to the surrounding rock but highlights the importance of preserving the thermocline. Even when neglecting thermal losses to the surrounding rock, a breached thermocline will require about 2.5 GWh of extra thermal energy to heat the thermal storage from 4 °C to 90 °C, as shown in the plots above.

In addition to preserving the thermocline, the surface area of the storage should be kept as small as possible to minimize thermal losses to the surrounding rock.

Simulating thermoclines enables effective design of thermal energy storage systems. Care must be taken with mesh alignment and turbulence modeling to accurately represent the thermocline. The position and direction of inlets need to be carefully considered to avoid mixing different thermal layers.

Compared to batteries, thermal energy storage can hold energy in the range of gigawatt-hours (GWh).

For simulating and designing thermal energy storage systems with a focus on thermoclines, the following Ansys technologies are typically used:

Ansys Fluent for advanced Computational Fluid Dynamics (CFD) simulations including flow dynamics, heat transfer, turbulence modeling, and thermocline behavior.

Ansys Mechanical to analyze structural integrity and thermal stresses in storage tanks and surrounding rock formations.

Ansys Mechanical have additionally the ability to simulate thermo-hydro-mechanical problems (THM). THM analyses are used to ensure that the surrounding rock of converted storage built decades ago do not fracture when converted into a thermal storage.

Ansys CFX, another CFD tool option for fluid flow and heat transfer, particularly suited for rotating machinery but also applicable in thermal storage.

Ansys Icepak mainly for electronics cooling but sometimes used for thermal management simulations that can relate to smaller-scale thermal storage.

AFRY helps organizations achieve a carbon-free future by taking brave, decisive steps toward a better tomorrow. AFRY and EDRMedeso have great input on interaction between natural convection and turbulence interaction in a previous project simulating thermal energy storage.

This case study is based on the “Meet the Experts” keynote presentation by Christoffer Källerman, held in Gothenburg on 6th May 2025.