Bruks Siwertell: utilizing simulation to optimize performance, reliability and efficiency in bulk handing operations

Design and Engineering Manager at Bruks Siwertell, Zoltan Habony, emphasizes the critical importance of reliability, efficiency, and environmentally friendly performance in the operation of unloaders, loaders, and conveyors:

“The challenge inherent in bulk material handling lies in the loading and unloading operations, irrespective of the technology employed, and the bottlenecks in these processes. The key issue revolves around the continuous availability of machinery for these operations. The challenge is twofold: ensuring the efficiency of loading and unloading procedures while minimizing downtime of the machinery.” Habony also highlights the financial repercussions of downtime, particularly when a ship is docked at its berth: “Costs are incurred by the ship for daily occupation of the docking space, and the longer the downtime, the greater the expenses will be for our customers.”

This economic consideration heightens the urgency for reliable and efficient loading and unloading solutions that minimize disruption and associated costs. Essentially, Bruks Siwertell must address the challenge of optimizing equipment reliability and performance to meet the industry’s demand for continuous and efficient ship loading and unloading operations, ultimately minimizing the financial impact on their customers.

Bruks Siwertell employs a comprehensive approach to optimize loading and unloading operations, incorporating robust support and maintenance. The key aspects of their solution include:

A Tailored Approach – no two projects are the same

Recognizing the diverse needs of their customers, Bruks Siwertell emphasizes a personalized approach. Each case is analyzed individually to provide customized solutions that address specific challenges.

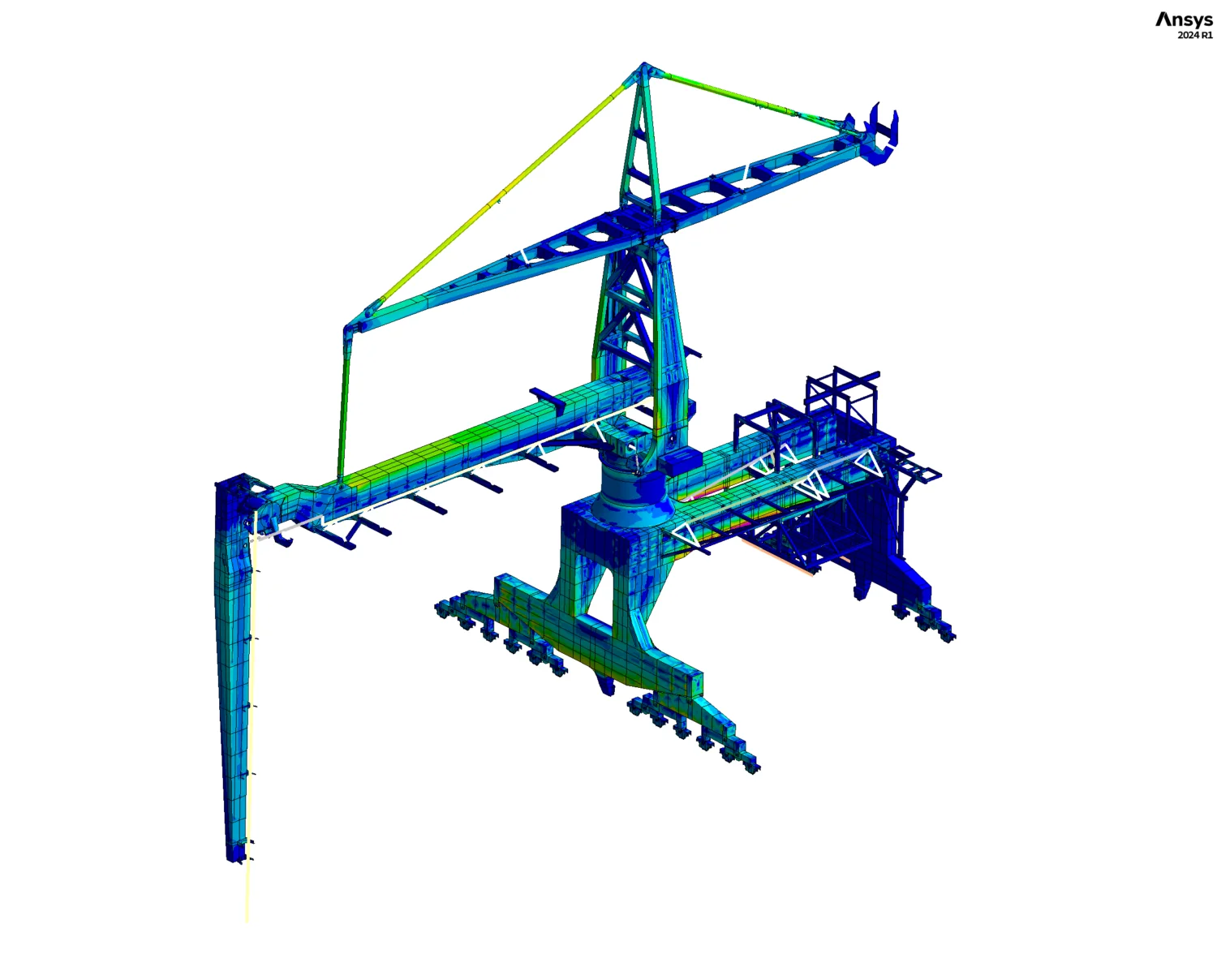

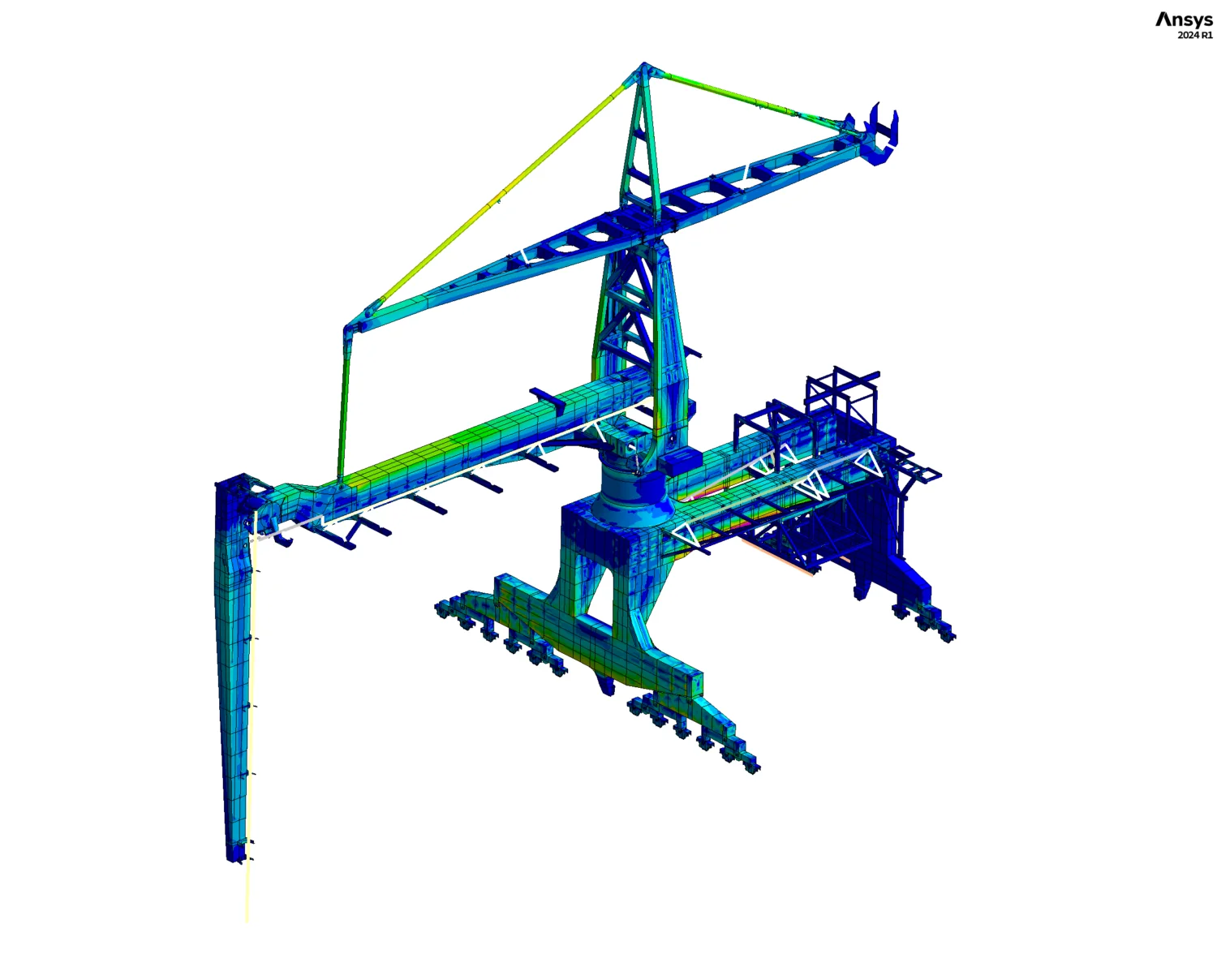

Simulation During Design

Utilizing Ansys Mechanical, Discovery, HPC, and Rocky, Bruks Siwertell employs proactive simulation-driven design during the design phase. This involves analyzing the entire machine and its structural components before delivery. This approach helps identify potential issues and ensures the efficiency and reliability of the equipment.

Adaptive Use of Simulation Post-Delivery

Bruks Siwertell acknowledges the crucial role that simulation plays in addressing challenges after equipment delivery. When issues arise on-site, simulation tools are employed to analyze the problem and find effective solutions. This adaptive use of simulation highlights its versatility in not only preventing issues during the design phase but also in troubleshooting and optimizing performance post-deployment. By incorporating these elements into their approach, Bruks Siwertell aims to enhance the overall efficiency, reliability, and performance of their loading and unloading solutions, thereby minimizing downtime and associated costs for their customers.

Simulation has played a crucial role in helping Bruks Siwertell achieve both engineering and business objectives. The clear benefits of simulation are in fostering innovation and creativity, reducing physical prototyping and minimizing wasted resources. Bruks Siwertell’s design goals center around improving the longevity of their machines, and the use of simulation aids in achieving this goal by optimizing structural designs to resist wear and tear, indirectly contributing to environmental sustainability by reducing the need for frequent replacements and associated resource consumption in the transportation chain. Zoltan Habony highlights that simulation and Ansys have been an invaluable part of Bruks Siwertell’s processes and acknowledges the added value of EDRMedeso’s technical support in developing its approach since 2005.

“Ever since we became an EDRMedeso customer I’ve never had any complaints. The support response time is always fast and when we have a time-critical issue, I can pick up the phone and get help instantly. That has been super helpful and brought added value to us here at Bruks Siwertell.”

– Zoltan Habony, Design and Engineering Manager, Bruks Siwertell.

Learn more about Bruks Siwertell