A Technological Revolution

Space technology is revolutionizing our world in ways we once thought impossible.

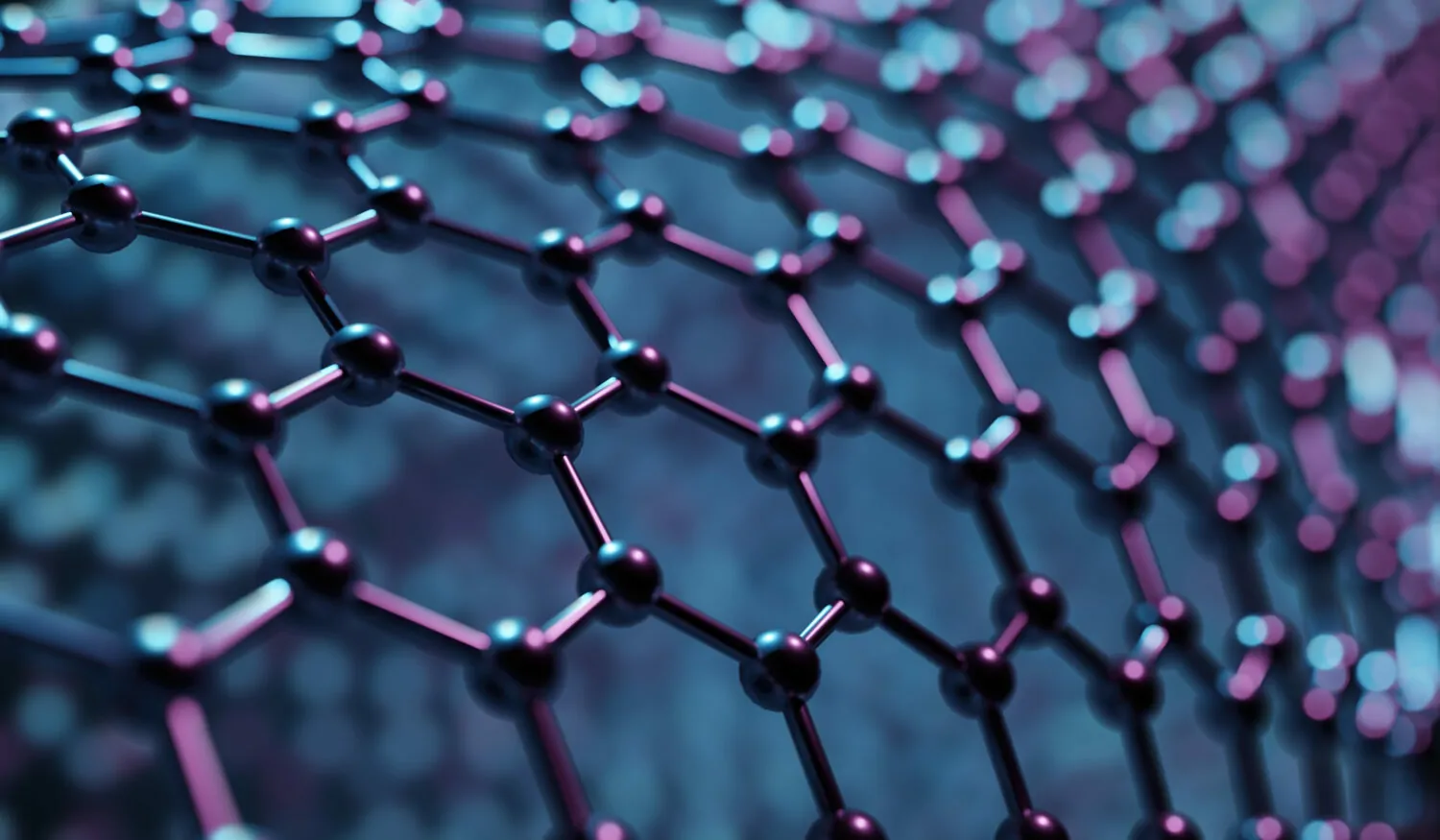

From satellite communications that connect the most remote corners of the Earth to advanced materials and manufacturing processes developed in microgravity, the innovations born out of space exploration are transforming industries.

Simulation Technology: The Key to Unlocking Space Innovation

Simulation technology is playing a crucial role in advancing space exploration and development.

Companies like EDRMedeso and Ansys are at the forefront of this revolution, providing cutting-edge simulation software that helps engineers and scientists model and test their designs in a virtual environment before they are physically built.

From secure and resilient communications to mission planning, novel propulsion technologies and accurate sensor systems, using the Ansys suite of products enables detailed simulations of spacecraft, rockets, and satellites, ensuring that they perform optimally and safely in the harsh conditions of space.

- Design launch systems, component, satellites and spacecraft

- Reduce the cost and time associated with physical testing

- Enhance the reliability and efficiency of space missions

Simulation Solutions for the Space Industry

Fueling the Innovation of Tomorrow

Simulation has the power to deliver insight beyond your wildest imagination.

From satellites to launch systems, components to spacecraft, simulation has the power to unlock new frontiers.

Launch your ideas beyond what you thought possible!

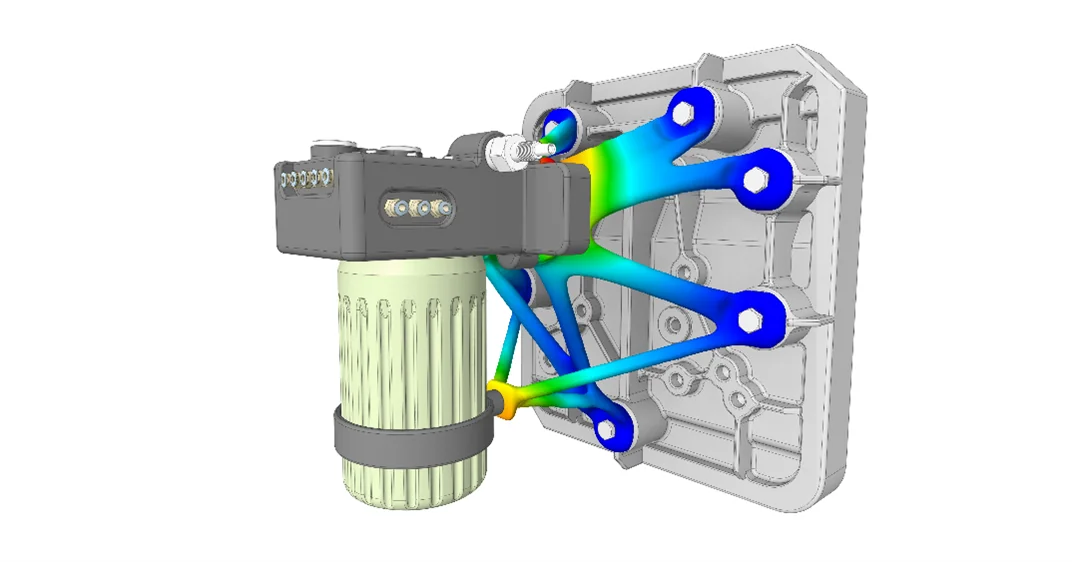

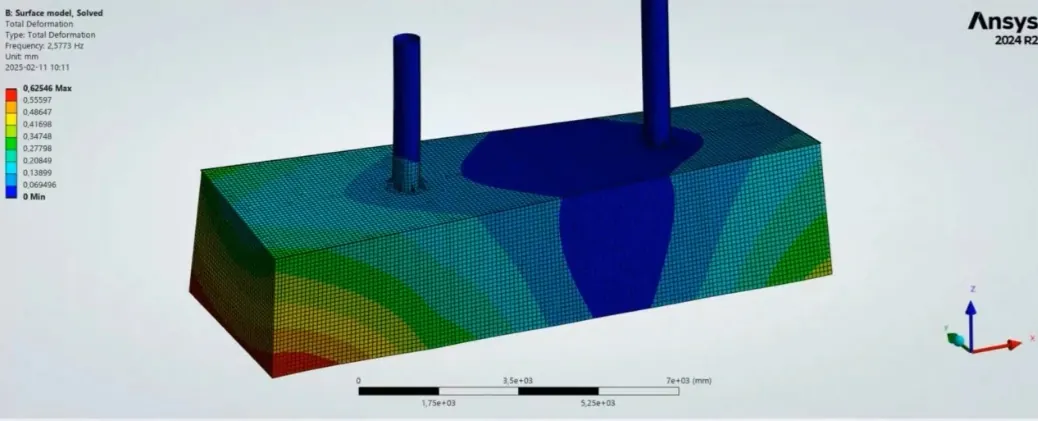

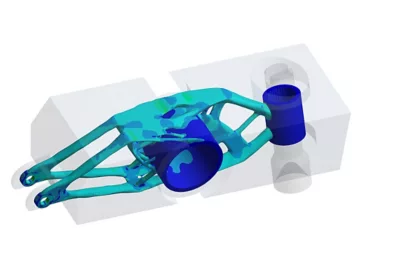

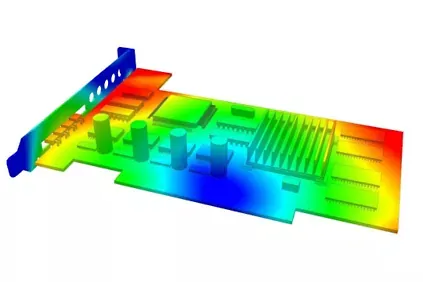

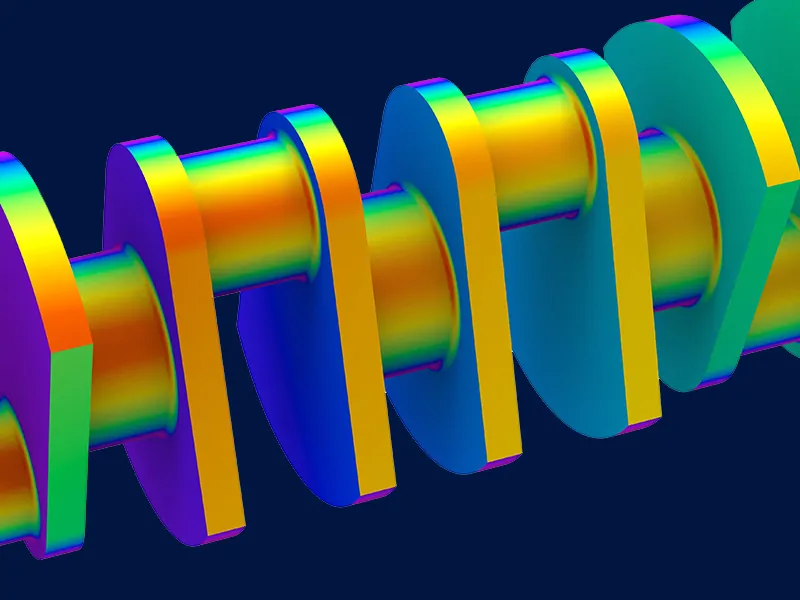

Structural Analysis for Space

Solving Complex Engineering Problems in Space with Ansys Structural Analysis Software

Solve complex structural engineering problems with structural analysis software from Ansys. Here, Rich Davies gives an introduction to structural analysis within a space context, touching on coupled thermal-optical and structural analysis, standalone mechanical analysis, impact modelling, PCB reliability, and composite assemblies.

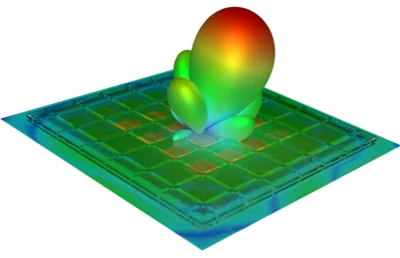

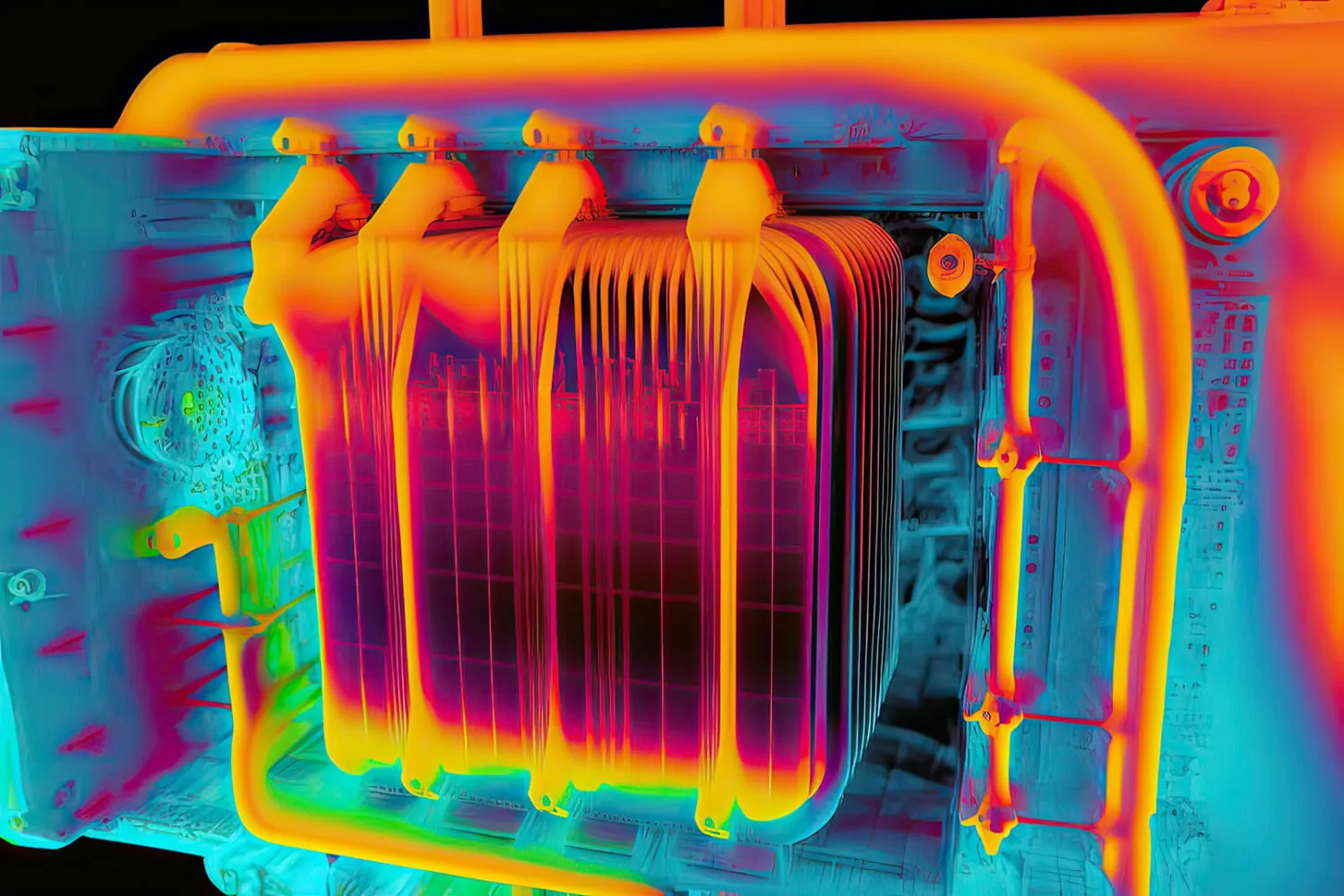

Electronic Simulation for Space

Electronic and Thermal Physics Simulation Tools for Space Applications

An overview of simulation’s role in critical high and low frequency electronic applications in Space Technology. Watch Dr Fatemeh Hoveizavi explore how Ansys simulation tools assist in communication and data transfer, phased array and beam steering, antenna performance, ESD and Thermal Analysis, and more.

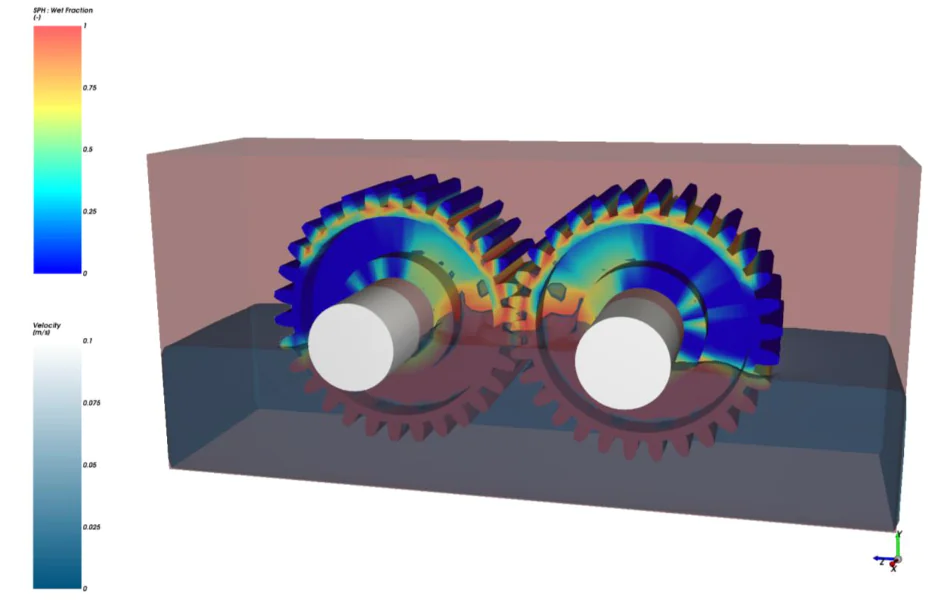

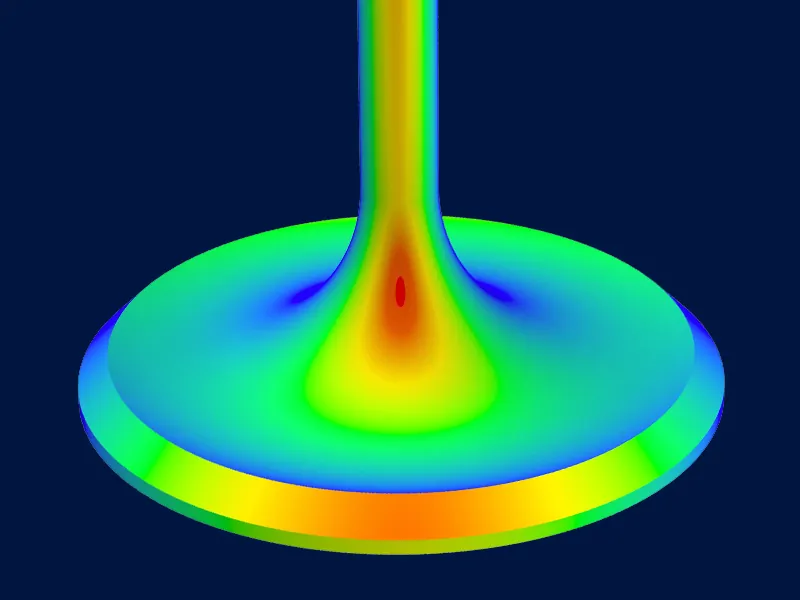

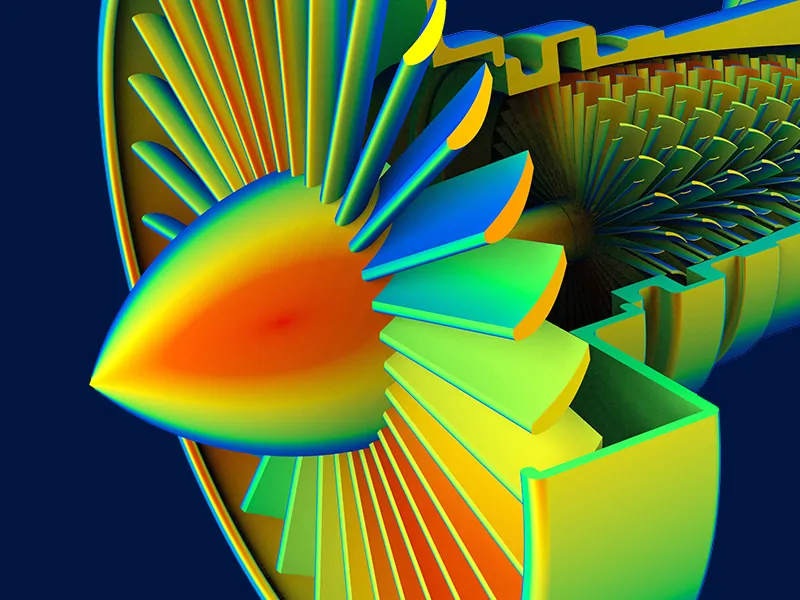

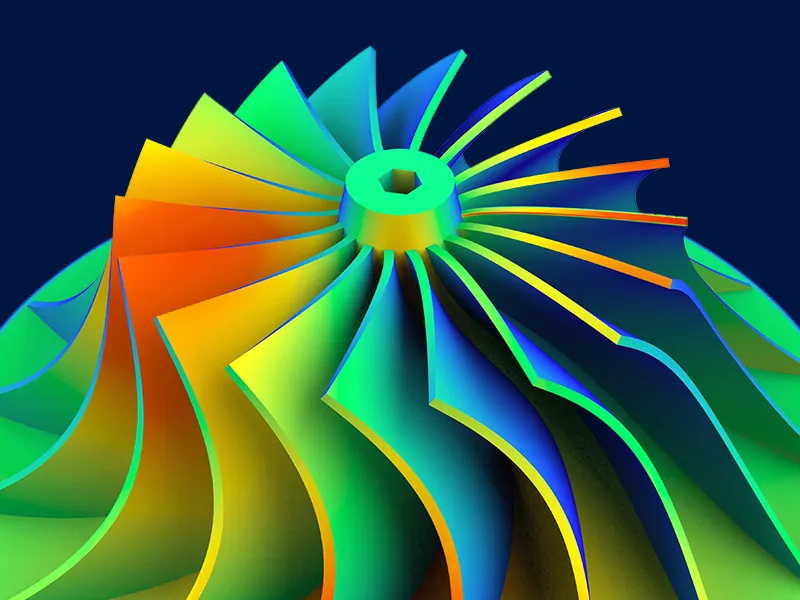

Fluids Simulation for Space

Solving Fluid Applications for Space with CFD tools from Ansys

A look over some of the uses and strengths of the Computational Fluid Dynamics (CFD) tools from Ansys for space projects. Our expert Stephen Silvester sets out how simulation can assist in the design process of key space engineering and research applications, from fuel sloshing to thermal and atmospheric impact.

Who We Have Helped

How We Can Help

At EDRMedeso we enable our customers to design better products, reduce risk, and accelerate time to market. We are committed to driving innovation by providing leading simulation technologies powered by knowledge transfer.

If you are looking for a partner to help you navigate the challenges of the Aerospace and Defense industries, we are here to help.

Our Recommended Applications

Speak to an Expert

Reach out to our experienced technical team for advice or support